Increasing Productivity by Reducing Tool Change time with Multicouplings

"Many manufacturing processes have interchangeable tooling in their machines. These tools require pneumatic, hydraulic, chemical, or electrical connections to operate. Instead of connecting individual connections one at a time, they can be connected at the same time."

Pneumatics and the Internet of Things: What's Holding Us Back?

Pneumatics has had different diagnostic features for some time. For example, we can sense today whether the power is too low or too high, or whether there is a short circuit in an I/O system which caused some sort of failure.

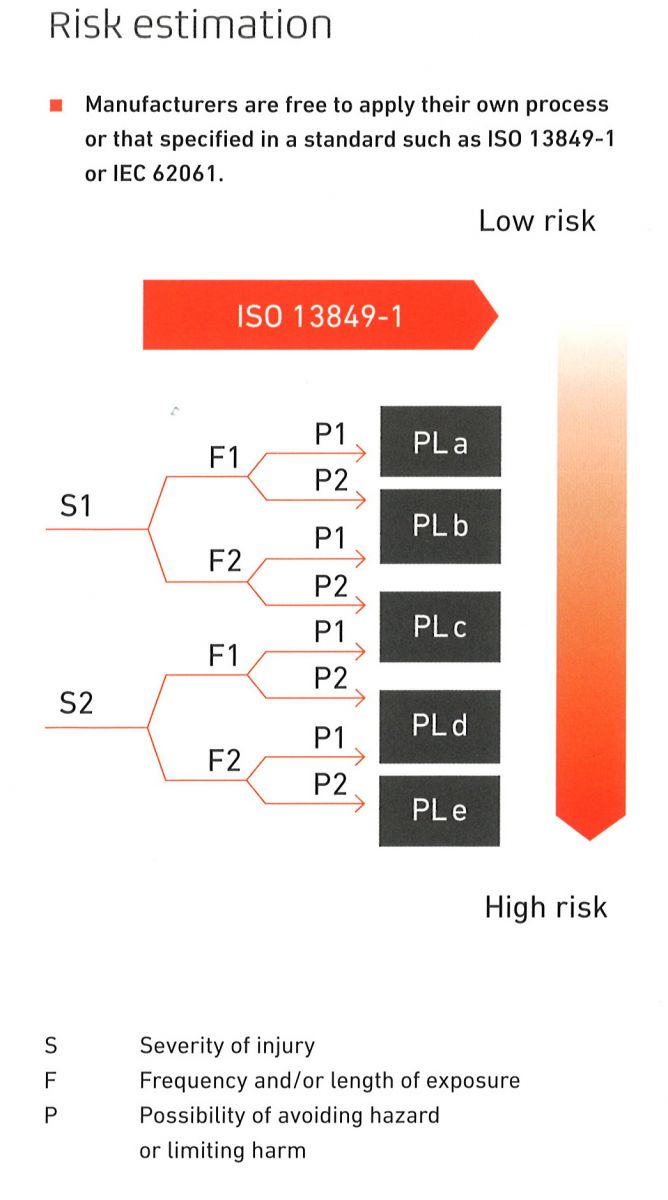

Designing Safe Pneumatic Circuits

Pneumatic circuits can be safe when carefully examined and implemented. The designers can use the appropriate level of reliability based on their assessment of the risk and frequency of the potential risk.

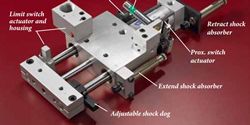

Selecting Pneumatic Linear Slides for Automated Assembly Equipment

Rather than sizing up to a slide model with very large diameter guideshafts, you may be able to use a smaller model with the addition of the optional center support.

Records 1 to 4 of 4

Featured Product

FLIR Si1-LD - Industrial Acoustic Imaging Camera for Compressed Air Leak Detection

The FLIR Si1-LD is an easy-to-use acoustic imaging camera for locating and quantifying pressurized leaks in compressed air systems. This lightweight, one-handed camera is designed to help maintenance, manufacturing, and engineering professionals identify air leaks faster than with traditional methods. Built with a carefully constructed array of MEMS microphones for high sensitivity, the Si1-LD produces a precise acoustic image that visually displays ultrasonic information, even in loud, industrial environments. The acoustic image is overlaid in real time on a digital image, allowing you to accurately pinpoint the source of the sound, with onboard analytics which quantify the losses being incurred. The Si1-LD features a plugin that enables you to import acoustic images to FLIR Thermal Studio suite for offline editing, analysis, and advanced report creation. Field analysis and reporting can also be done using the FLIR Acoustic Camera Viewer cloud service. Transferring of images can be managed via memory stick or USB data cable. Through a regular maintenance routine, the FLIR Si1-LD can help facilities reduce their environmental impact and save money on utility bills.

Manufacturing and Automation - Featured Company

Encoder Products Company

At Encoder Products Company, we specialize in the encoders that provide you with motion feedback. EPC has been a leading designer and manufacturer of motion sensing devices for more than 50 years, we understand that each industrial automation application is different, and you need encoders that fit the needs of your applications. Our encoders are highly configurable, offer an array of shaft or bore sizes, output types, connector types, mounting options, and resolutions as high as 65,536 CPR.

.jpg)