Ex-NASA Engineer Now Guiding Manufacturers to Greater Efficiency

David Altemir, Founder of Altemir Consulting manufacturing consultancy from Dallas, used to build rocket ships. Today, he has his feet firmly planted on the shop floor, helping manufacturers across America improve their operational efficiency.

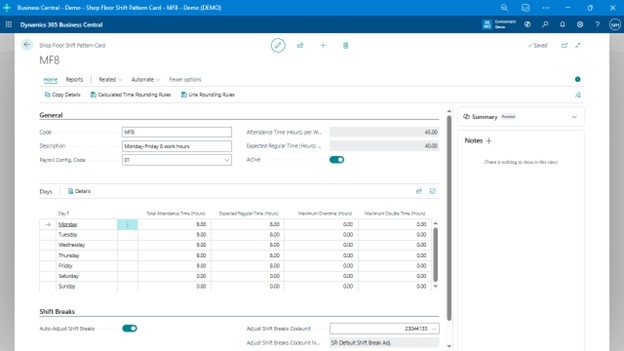

Why Manual Time Tracking in Business Central Is Costing Your Shop Floor More Than You Think

By automating time collection through barcode scanning, manufacturers gain precise labor costing, improved accountability, and a clearer picture of shop floor performance.

Smart Automation: How AGVs and AMRs Help Manufacturers Manage Rising Costs

The time is now to invest in scalable, cost-efficient automation deployments, keeping in mind the importance of power and data delivery solutions that support consistent, productive operations.

AI for Product Data Management: A Key Component for Smarter Manufacturing

AI improves data quality by reducing errors and inconsistencies introduced by manual intervention. Manual errors may not seem like a huge deal, but they can easily disrupt time-to-market or channel accuracy.

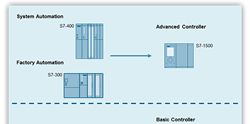

Upgrading for Industry 4.0: How Siemens S7-1500 Migration Solves Hidden Legacy Challenges and Why Modern Manufacturing Can't Afford to Wait

This article explains why migration to the S7-1500 platform is becoming urgent, the hidden challenges engineers face during transition, and how modern PLC architecture supports Industry 4.0 readiness, improved reliability, and long-term performance.

Driving Performance Improvement on the Shop Floor with Production Data

One of my favorite customer lines is, "I need parts, not charts." And that really captures what Datanomix is about: helping manufacturers solve real business problems by clearly showing what's happening on their shop floor.

Rugged Surface Pro xCase with Badge Readers Elevates Workforce Safety & Mustering for Umicore

When global materials technology and recycling leader Umicore set out to modernize employee tracking and emergency mustering processes, they turned to Savance Workplace for a customized digital workforce management solution.

Discovering Manufacturing Bottlenecks Through AI and Machine Learning Analysis

Manufacturing slowdowns come from many sources. That diversity makes it challenging for executives to identify the top causes without help. Well-trained AI and machine learning algorithms can analyze the data and recommend suggestions for improvement.

How private 5G empowers manufacturers to maximize AI use cases

While Wi-Fi networks have historically met the basic wireless connectivity needs of some manufacturing operations, they increasingly fall short in more complex, high-demand industrial environments.

2025 Top Article - Common Misconceptions Manufacturers have about AI

With over 25 years of experience advising mid-market companies, Ghori provides a grounded yet progressive-looking take on where manufacturers should focus, what misconceptions to avoid, and how to get started without overhauling everything.

2025 Top Article - Monitoring Tools for Manufacturing Plant Maintenance

Electrical power delivery systems are usually the most impactful on plant operation. The cost of failure of certain pieces of equipment can quickly escalate into multi-millions of dollars of equipment replacement costs and production downtime.

2025 Top Article - The Rise of AI in Manufacturing to Collect and Use Data

While AI and machine learning systems typically require around two years to collect enough data to reach their full potential, manufacturers can start seeing benefits almost immediately with basic analysis tools and dashboards.

Case Study from Nord - A Heavy Lift

How OMi Crane Systems works with NORD DRIVESYSTEMS to keep manufacturing moving. For OMi Cranes and its customers alike, having a reliable drive system supplier isn't just about convenience, it's about keeping material moving efficiently and without fail.

Beyond the Device: The Real Drivers of Industrial Mobility

Accessories don't just complement rugged devices, they complete them. They turn durability into productivity, resilience into results, and hardware into workflow platforms.

Why B2B IAM Is Essential for Modern Manufacturing

VPN access is widely used without strong safeguards regarding whether those users should be trusted or what they're entitled to access. Cybercriminals are increasingly targeting VPN setups.

Records 1 to 15 of 1803

Automation & IIoT - Featured Product

Model TR1 Tru-Trac

The Model TR1 Tru-Trac® linear measurement solution is a versatile option for tracking velocity, position, or distance over a wide variety of surfaces. An integrated encoder, measuring wheel, and spring-loaded torsion arm in one, compact unit, the Model TR1 is easy to install. The spring-loaded torsion arm offers adjustable torsion load, allowing the Model TR1 to be mounted in almost any orientation - even upside-down. The threaded shaft on the pivot axis is field reversible, providing mounting access from either side. With operating speeds up to 3000 feet per minute, a wide variety of configuration options - including multiple wheel material options - and a housing made from a durable, conductive composite material that minimizes static buildup, the Model TR1 Tru-Trac® is the ideal solution for countless applications.

Manufacturing and Automation - Featured Company

maxon group

maxon is a leading supplier of high-precision DC brush and brushless servo motors and drives. These motors range in size from 4 - 90 mm and are available up to 500 watts. We combine electric motors, gears and DC motor controls into high-precision, intelligent drive systems that can be custom-made to fit the specific needs of customer applications.

.jpg)

.jpg)