3D Printed Buoy Gives Voice to Berlin's River Spree

A 3D-printed buoy uses sensors and solar power to reveal the health of Berlin's River Spree and engage the city with its main river. To meet the project's requirements for scale, durability, and sustainability, Jakob partnered with BigRep.

Ex-NASA Engineer Now Guiding Manufacturers to Greater Efficiency

David Altemir, Founder of Altemir Consulting manufacturing consultancy from Dallas, used to build rocket ships. Today, he has his feet firmly planted on the shop floor, helping manufacturers across America improve their operational efficiency.

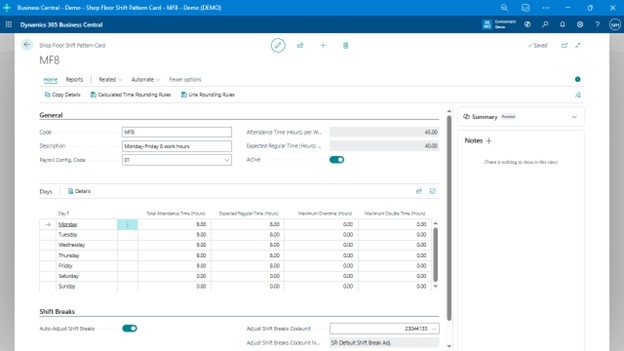

Why Manual Time Tracking in Business Central Is Costing Your Shop Floor More Than You Think

By automating time collection through barcode scanning, manufacturers gain precise labor costing, improved accountability, and a clearer picture of shop floor performance.

Smart Automation: How AGVs and AMRs Help Manufacturers Manage Rising Costs

The time is now to invest in scalable, cost-efficient automation deployments, keeping in mind the importance of power and data delivery solutions that support consistent, productive operations.

AI for Product Data Management: A Key Component for Smarter Manufacturing

AI improves data quality by reducing errors and inconsistencies introduced by manual intervention. Manual errors may not seem like a huge deal, but they can easily disrupt time-to-market or channel accuracy.

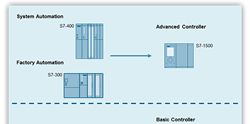

Upgrading for Industry 4.0: How Siemens S7-1500 Migration Solves Hidden Legacy Challenges and Why Modern Manufacturing Can't Afford to Wait

This article explains why migration to the S7-1500 platform is becoming urgent, the hidden challenges engineers face during transition, and how modern PLC architecture supports Industry 4.0 readiness, improved reliability, and long-term performance.

Driving Performance Improvement on the Shop Floor with Production Data

One of my favorite customer lines is, "I need parts, not charts." And that really captures what Datanomix is about: helping manufacturers solve real business problems by clearly showing what's happening on their shop floor.

Rugged Surface Pro xCase with Badge Readers Elevates Workforce Safety & Mustering for Umicore

When global materials technology and recycling leader Umicore set out to modernize employee tracking and emergency mustering processes, they turned to Savance Workplace for a customized digital workforce management solution.

Discovering Manufacturing Bottlenecks Through AI and Machine Learning Analysis

Manufacturing slowdowns come from many sources. That diversity makes it challenging for executives to identify the top causes without help. Well-trained AI and machine learning algorithms can analyze the data and recommend suggestions for improvement.

How private 5G empowers manufacturers to maximize AI use cases

While Wi-Fi networks have historically met the basic wireless connectivity needs of some manufacturing operations, they increasingly fall short in more complex, high-demand industrial environments.

2025 Top Article - Common Misconceptions Manufacturers have about AI

With over 25 years of experience advising mid-market companies, Ghori provides a grounded yet progressive-looking take on where manufacturers should focus, what misconceptions to avoid, and how to get started without overhauling everything.

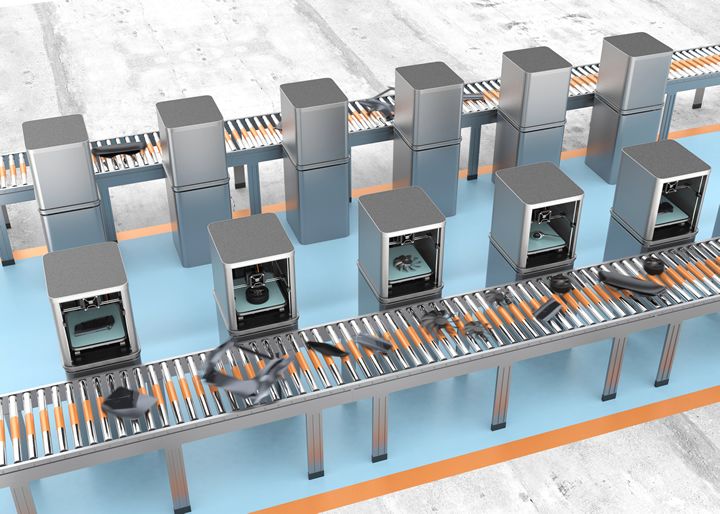

2025 Top Article - AUTOMATION IS UNLOCKING THE FUTURE OF AM SERVICES

In this article, I want to dive into the role automation plays in the approach to AM services, highlighting the benefits it delivers to customers, how it drives operational efficiency, and why it's essential for the future of this industry.

2025 Top Article - Monitoring Tools for Manufacturing Plant Maintenance

Electrical power delivery systems are usually the most impactful on plant operation. The cost of failure of certain pieces of equipment can quickly escalate into multi-millions of dollars of equipment replacement costs and production downtime.

2025 Top Article - How Industrial 3D Printing is Propelling Small and Mid-Sized Manufacturers Forward

With lower barriers to entry, small and mid-sized manufacturers have more opportunities than ever to integrate industrial 3D printing into their operations while avoiding the hurdles that once held them back.

2025 Top Article - The Rise of AI in Manufacturing to Collect and Use Data

While AI and machine learning systems typically require around two years to collect enough data to reach their full potential, manufacturers can start seeing benefits almost immediately with basic analysis tools and dashboards.

Records 1 to 15 of 3082

Featured Product

NVIDIA RTX PRO™ BLACKWELL DESKTOP GPUs N

NVIDIA RTX PRO™ - Built for Professionals - NVIDIA RTX PRO Blackwell Desktop GPUs feature the latest breakthroughs in AI, ray tracing, and neural rendering technology to power the most innovative workflows in design, engineering, and beyond.

Manufacturing and Automation - Featured Company

EXAIR

EXAIR intelligent compressed air® products solve problems in industrial plants while reducing compressed air consumption and increasing safety for personnel. We have the largest variety of sizes, materials and performance characteristics in order to provide the best solution for your processes and problems.

Our products are commonly used to conserve air, cool processes or parts, convey material, clean surfaces or coat surfaces. EXAIR's 15 extensive product lines include air knives, air wipes, air nozzles and jets, atomizing nozzles, static eliminators, cold gun air coolant systems, air amplifiers, safety air guns, air operated conveyors, industrial housekeeping products, vortex tubes and spot cooling products, cabinet cooler systems, vacuum generators, compressed air optimization products, and associated accessories.

Products meet OSHA standards and are CE and RoHS compliant. Five-year warranty on compressed air products and one-year warranty on accessories and electrically powered products.

.jpg)

.jpg)