The market demand for solutions that combine high performance, compact size, and high reliability is rapidly increasing, especially in harsh environments such as smart manufacturing.

Computers for Edge AI, Machine Vision, and Industrial Automation Applications

Computers for Edge AI, Machine Vision, and Industrial Automation Applications

Q&A with Cindy Lin | Cincoze

Tell us about yourself and your role with Cincoze.

I am Cindy Lin, currently serving as the Senior Marketing Manager at Cincoze. I have been with Cincoze for five years and have nearly 20 years of marketing experience in the IT industry, focusing on brand strategy planning, product marketing, and global promotion.

At Cincoze, I am responsible for overall brand positioning and product promotion, helping to establish the company as a trusted global brand in the industrial computer market. I also actively plan and execute international exhibitions, digital marketing initiatives, and media collaborations to enhance Cincoze’s brand visibility and strengthen connections with target customers.

I believe that Cincoze’s industrial computer products are developed from deeply understanding customer needs and solving their pain points, combining innovative technology with high reliability to deliver the best solutions for demanding applications worldwide, ultimately helping customers create greater value and achieve a stronger competitive advantage.

What are Cincoze’s main product lines and core markets?

Cincoze is a brand manufacturer dedicated to providing embedded computing systems for edge AI and industrial computing applications. We market our high-quality brand 'Cincoze' globally, with the brand name derived from 'synchronize,’ reflecting our commitment to seamlessly integrate with customer applications. Cincoze designs, develops, manufactures, and sells rugged embedded computers for harsh environments and critical applications.

Founded in 2012, Cincoze has built a strong reputation over 12 years as a high-end and professional brand. As an own-brand manufacturer with no OEM or ODM operations and 100% of products designed and made in Taiwan, we stand apart from other industrial computer manufacturers.

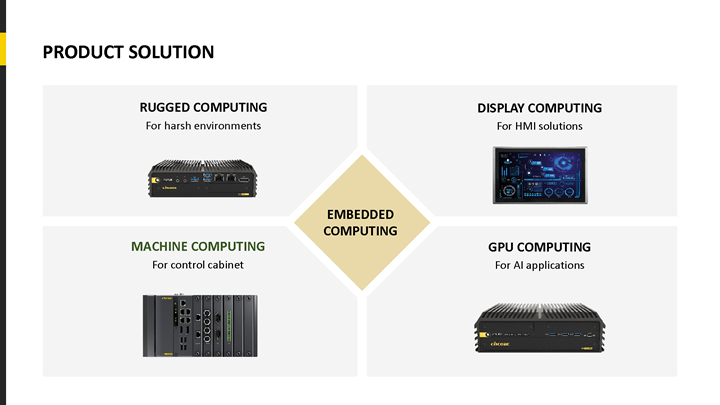

Cincoze focuses on embedded computing technologies and has developed four major product lines to deliver comprehensive computing solutions:

• Rugged Computing — Rugged computers designed for harsh industrial environments.

• Display Computing – Panel PCs and touch monitors providing comprehensive HMI solutions.

• GPU Computing – GPU computers for high-performance applications such as AI inference, machine vision, and image analysis.

• Machine Computing – DIN-Rail computers for installation in control cabinets, enabling machine vision and other industrial applications.

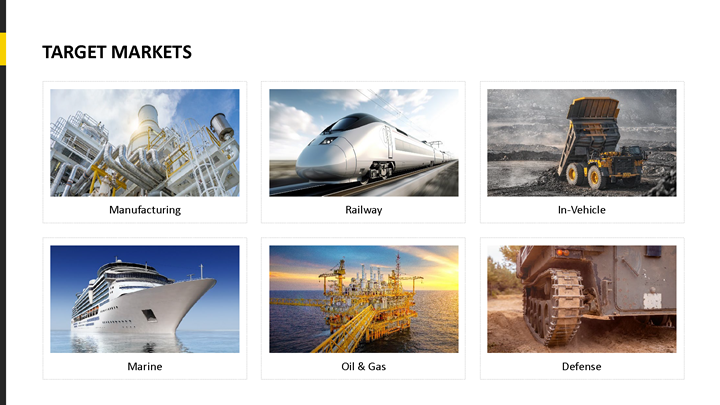

Cincoze focuses on key vertical markets including manufacturing, railway, in-vehicle, energy & environment, marine, and defense. Our products have been sold in more than 50 countries worldwide, with the U.S. and Europe as our primary markets.

Cincoze solutions are widely deployed in demanding applications, such as production lines of major international EV manufacturers, metro trains and station systems across Europe, key airport facilities in Northeast Asia, manufacturing sites of global electronics brands, and production lines of leading global automotive brands.

How do you differentiate your product design in a highly competitive industry?

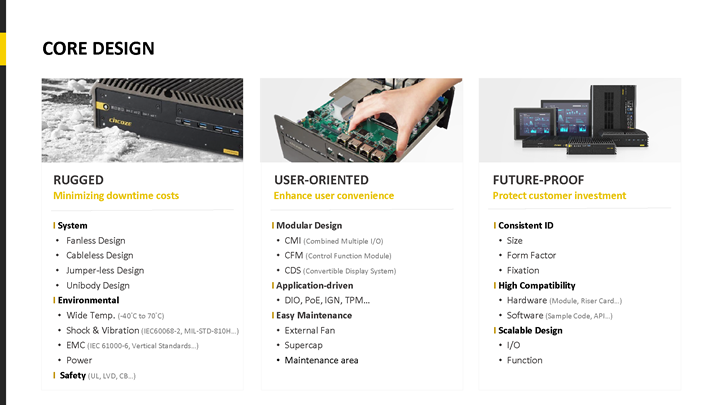

Cincoze embedded computers are designed with three main features: ruggedness, user-oriented design, and future-proofing, helping to reduce downtime costs, enhance operational convenience, and extend equipment lifespan to maximize customer investment value. These three features enable Cincoze to achieve differentiated competitiveness in the market.

• Ruggedness — Minimized Downtime Costs

Cincoze embedded computers use industrial-grade components from the beginning and adopt many fanless, cableless, jumper-less designs. They are also proven by compliance with multiple international certifications and standards that demonstrate their high reliability. Thanks to this reliability, downtime costs can be minimized. For environmental adaptability, Cincoze computers undergo tests for wide temperature ranges, shock, and vibration resistance to overcome harsh environmental challenges. EMC tests include standards for ESD (electrostatic discharge), RS (radiation susceptibility), EFT (electrical fast transient), and surge protection, ensuring reliable performance in various applications. In terms of safety, Cincoze embedded computers have passed certifications such as UL safety standards in the U.S. and LVD (Low Voltage Directive), further safeguarding both users and equipment.

• User-Oriented Design — Enhanced Operational Convenience

Cincoze embedded computers are designed to address needs across different stages of use, ensuring user convenience. In the pre-sales stage, modular design allows flexible configuration to provide quick solutions. During deployment, application-driven features such as PoE and IGN simplify and accelerate the installation process. In operation, Cincoze computers feature maintenance-friendly designs, such as grouping critical switches and settings in a front maintenance area and supporting front-access hot-swappable hard drives, helping customers save time and reduce maintenance costs.

• Future-Proofing — Long-Term Value and Extended Equipment Lifespan

Cincoze embedded computers feature product series consistency and flexible expansion capabilities, effectively preserving the long-term value of equipment assets. This is reflected in three aspects: First, the consistent ID design within each product series—including dimensions, size, and mounting hole positions—allows customers to upgrade to next-generation products without redesigning their mechanical setup. Second, high compatibility enables modules and interfaces from previous generations to be reused in new models, achieving seamless upgrades. Finally, scalable design makes it easy to meet future needs for additional I/O or new functions, allowing equipment to be used over the long term. This ensures greater sustainability and flexibility for equipment investment, further protecting customer assets.

What inspired the development of the GM-1100?

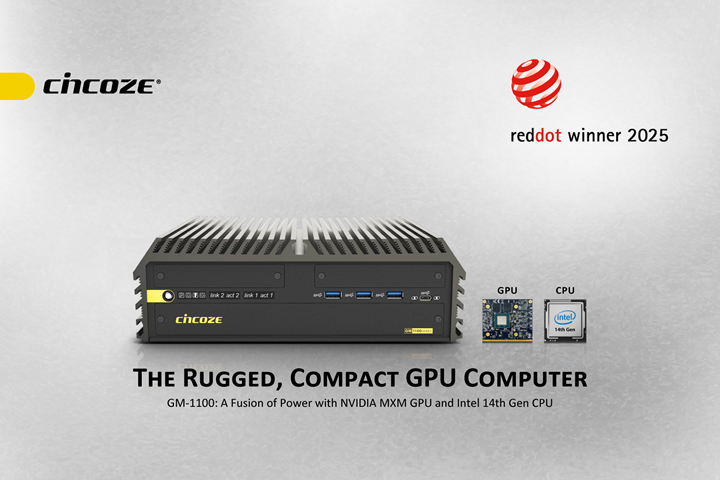

The GM-1100 is a GPU computer designed for space-constrained edge AI applications. The market demand for solutions that combine high performance, compact size, and high reliability is rapidly increasing, especially in harsh environments such as smart manufacturing, in-vehicle systems, and railway applications. However, most GPU computers on the market struggle to balance performance, size, and environmental adaptability. Seeing this market gap, Cincoze launched the GM-1100, focusing on the combined needs of「Performance × Compact × Ruggedã€, delivering a stable, high-performance, and rugged edge AI solution within a compact footprint.

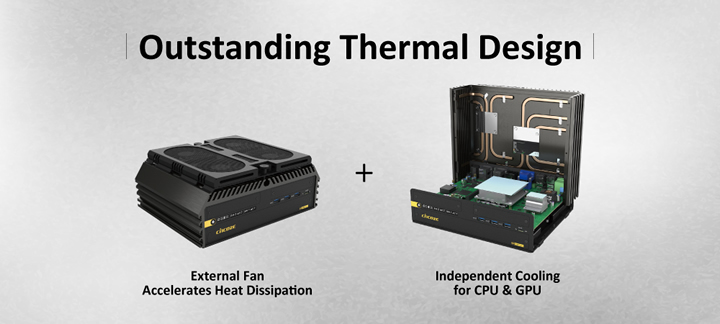

What are the unique design features that make the GM-1100 stand out in the Edge AI space?

CPU + GPU Dual Engines Drive Edge AI Applications

The GM-1100 is an embedded MXM GPU computer specifically designed for edge AI, machine vision, and industrial automation applications. It is equipped with a 14th Gen Intel® Core™ 65W CPU and supports MXM Type A/B GPU modules, delivering powerful CPU + GPU collaborative computing performance. With high-speed I/O (such as 10GbE LAN and USB 3.2 Gen2x2 Type-C) and flexible storage options (2 x 2.5" hot-swappable drives and NVMe SSDs), it can integrate multiple sensors and image capture devices to enable real-time data processing as well as high-speed transmission and storage, fully meeting the demands of various edge AI applications.

Compact, Rugged, and Ready for Harsh Environments

With a compact footprint of only 260 × 200 × 85 mm, the GM-1100 supports multiple mounting options, making it ideal for space-constrained applications. It features industrial-grade protections such as wide temperature support (-40–70°C) and wide voltage input (9–48V), and has passed numerous international certifications, including MIL-STD-810H (U.S. military shock and vibration standard), E-Mark for in-vehicle use, EN 50155 for railway applications, and UL safety standards. These ensure long-term stable operation even in the harshest environments.

Application-Oriented High Expandability

The GM-1100 features outstanding modular I/O design that can be flexibly expanded based on application needs, enhancing deployment efficiency, reducing integration costs, and supporting future upgrades. For different vertical markets, various I/O modules can be selected — for example, M12 LAN connectors for railway applications to enhance anti-vibration performance and connection stability, or 10GbE LAN expansion for machine vision applications to support high-speed image transmission. Additionally, to meet the demanding GPU performance requirements of edge AI, the GM-1100 adopts a special carrier board design that supports various MXM Type A/B modules. This enables flexible options ranging from lightweight AI tasks to high-end AI inference workloads, delivering maximum flexibility for different application scenarios.

With these design advantages, the GM-1100 was also honored with the 2025 Red Dot Design Award (Product Design), further highlighting its exceptional functionality and innovation.

How does the GM-1100 solve common challenges in deploying AI at the edge?

Which application scenarios are best suited for this model?

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product