Manufacturing and Automation - Articles, Stories & Interviews

Smart Automation: How AGVs and AMRs Help Manufacturers Manage Rising Costs

The time is now to invest in scalable, cost-efficient automation deployments, keeping in mind the importance of power and data delivery solutions that support consistent, productive operations.

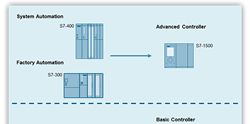

Upgrading for Industry 4.0: How Siemens S7-1500 Migration Solves Hidden Legacy Challenges and Why Modern Manufacturing Can’t Afford to Wait

This article explains why migration to the S7-1500 platform is becoming urgent, the hidden challenges engineers face during transition, and how modern PLC architecture supports Industry 4.0 readiness, improved reliability, and long-term performance.

Driving Performance Improvement on the Shop Floor with Production Data

One of my favorite customer lines is, “I need parts, not charts.” And that really captures what Datanomix is about: helping manufacturers solve real business problems by clearly showing what’s happening on their shop floor.

Rugged Surface Pro xCase with Badge Readers Elevates Workforce Safety & Mustering for Umicore

When global materials technology and recycling leader Umicore set out to modernize employee tracking and emergency mustering processes, they turned to Savance Workplace for a customized digital workforce management solution.

2025 Top Article - Common Misconceptions Manufacturers have about AI

With over 25 years of experience advising mid-market companies, Ghori provides a grounded yet progressive-looking take on where manufacturers should focus, what misconceptions to avoid, and how to get started without overhauling everything.

2025 Top Article - AUTOMATION IS UNLOCKING THE FUTURE OF AM SERVICES

In this article, I want to dive into the role automation plays in the approach to AM services, highlighting the benefits it delivers to customers, how it drives operational efficiency, and why it’s essential for the future of this industry.

2025 Top Article - Monitoring Tools for Manufacturing Plant Maintenance

Electrical power delivery systems are usually the most impactful on plant operation. The cost of failure of certain pieces of equipment can quickly escalate into multi-millions of dollars of equipment replacement costs and production downtime.

Manufacturing and Automation - Featured Stories

AI for Product Data Management: A Key Component for Smarter Manufacturing

.jpg)

AI improves data quality by reducing errors and inconsistencies introduced by manual intervention. Manual errors may not seem like a huge deal, but they can easily disrupt time-to-market or channel accuracy.

Discovering Manufacturing Bottlenecks Through AI and Machine Learning Analysis

.jpg)

Manufacturing slowdowns come from many sources. That diversity makes it challenging for executives to identify the top causes without help. Well-trained AI and machine learning algorithms can analyze the data and recommend suggestions for improvement.

How private 5G empowers manufacturers to maximize AI use cases

While Wi-Fi networks have historically met the basic wireless connectivity needs of some manufacturing operations, they increasingly fall short in more complex, high-demand industrial environments.

Manufacturing and Automation - News Headlines

Anti-Static Ion Air Cannon is CE, UL and RoHS Certified

New design features include a metal armored high voltage cable to protect against abrasion and cuts, a replaceable emitter point, integrated ground connection and electromagnetic shielding.

3D PEOPLE HELPS POWER BREAKTHROUGH MARITIME SUSTAINABILITY WITH ARMADA TECHNOLOGIES' PASSIVE AIR LUBRICATION SYSTEM

Armada Technologies, a Liverpool-based firm on a mission to reduce the environmental impact of global shipping, turned to 3D People to manufacture a critical part for its revolutionary Passive Air Lubrication System (PALS).

Replique Expands Global Manufacturing Partnership with Alstom

Replique now serves as a global supplier for numerous projects and subsidiaries, including locations in Singapore, Brazil, Australia, France, Italy, Germany, Thailand, and Spain.

Datalogic Launches Smart Vision Suite for Retail: The Industry's First All-in-One Embedded AI Software Solution for Real-Time Loss Prevention at Checkout

Datalogic, a global leader in automatic data capture and industrial automation, proudly announces the launch of Smart Vision Suite for Retail, a new AI-driven portfolio of software solutions designed to enhance loss prevention and checkout efficiency in retail environments, directly embedded in the updated Magellan™ 9600i and 9900i scanner platforms.

Challenging Weather and Lighting Conditions Prove No Problem for the New Flir FCB-Series AI Infrared Analytics Camera

New Thermal Sensor with Deep-Learning Video Analytics Safeguards Locations by Detecting, Tracking and Analyzing All Perimeter Breaches.

Manufacturing and Automation - Featured Product

Rapid Prototyping with the Modular Motor Series

Quick to configure. Quick to build. Quick to deliver. Parvalux understands the importance of getting product in the hands of customers quickly and efficiently. The Modular Range does just that allowing customers to configure their own solution, selecting motor and gearbox, adding encoders and brakes to create a solution perfectly suited for their specific applications such as conveyor belt systems, picking systems, parcel sorting equipment, pallet shuttles and automated storage and retrieval systems (ASRS). Read our modular range guide for specifics.

Manufacturing and Automation - Featured Company

Teledyne FLIR

Teledyne FLIR designs, develops, manufactures, markets, and distributes technologies that enhance perception and awareness. We bring innovative sensing solutions into daily life through our thermal imaging, visible-light imaging, video analytics, measurement and diagnostic, and advanced threat detection systems. Teledyne FLIR offers a diversified portfolio that serves a number of applications in government & defense, industrial, and commercial markets. Our products help first responders and military personnel protect and save lives, promote efficiency within the trades, and innovate consumer-facing technologies. Teledyne FLIR strives to strengthen public safety and well-being, increase energy and time efficiency, and contribute to healthy and intelligent communities.