How Microfactories Can Bring Iterative Manufacturing to the Masses

ANDREW O'KEEFE and JASON DORRIER for Singularity Hub: Humans manufacture a mind-numbing amount of stuff each year—ever wonder how we do it?

ANDREW O'KEEFE and JASON DORRIER for Singularity Hub: Humans manufacture a mind-numbing amount of stuff each year—ever wonder how we do it?

In the past 100 or more years, it’s been all about economies of scale. This means you should make a lot of a thing because the more you make, the more your fixed expenses get spread out. This reduces the cost of each unit, from light bulbs to iPhones. Here’s the problem. It’s expensive to do a big manufacturing run. So, how do you know what to make in the first place?

Often, it’s an educated guess based on prototypes and limited feedback, but you don’t really know until you try to sell a product—and by then, you’re fully committed, succeed or fail.

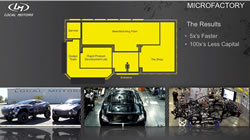

Jay Rogers of Local Motors wants to upend common wisdom. Manufacturers should run through tons ofpotentially good ideas and then test them out to see if people actually want what they’re making before going full scale. And Rogers thinks microfactories are the way to do it. Cont'd...

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product