Products are becoming more and more complicated-and manufacturers are having a harder time keeping up. 92% of manufacturers have reported that their products have become more complex over the last half-decade.

Cloud-Based Data Storage - The Future of Agile Manufacturing

Cloud-Based Data Storage - The Future of Agile Manufacturing

Maziar Adl, Software, Technology and Information Systems Executive | Gocious

Products are becoming more and more complicated—and manufacturers are having a harder time keeping up. 92% of manufacturers have reported that their products have become more complex over the last half-decade. This complexity isn’t limited to incorporating the software and circuitry that comprise the IoT—even purely mechanical designs have become more intricate.

In addition to this finding, only 15% of manufacturers were tackling this increase in complexity via systems such as requirements management software. In other words, these manufacturers were still deploying linear development processes against product requirements that have become multidimensional. Complex products lengthen the development lifecycle by their very nature. Continuing in the use of outdated design processes is no way to cope.

How do linear manufacturing processes fail to hold up?

A traditional manufacturing design process typically has a series of bottlenecks. Each department completes its stage of the work, there’s a holdup while it’s approved, and their work is passed along to the next department in line. There are legacy systems and data silos that are underpinning these processes. Even though 86% of manufacturers have adopted advanced solutions such as the Industrial Internet of Things (IIoT), adopters still have to worry about issues such as siloed data. Companies might collect data only from their new manufacturing equipment, equipment from different vendors might end up in incompatible formats, and raw data might defy analysis. Similar issues can occur with marketing, product, and design data, even if these departments are using the newest tools.

If data remains in silos, then it becomes difficult to access across the organization. Getting access to this data slows down critical processes, and if data can’t be accessed, then companies can end up making important decisions in error.

Make Manufacturing Agile at the Start

Agile isn’t a software development term anymore. When applied to manufacturing, processes can cope better with complexity, shorten development lifecycles, and meet accelerating customer demands.

It starts with the Cloud.

The Cloud has massive potential to break down silos and democratize access to information across a large organization—even in organizations where continents separate the product developers and manufacturing facilities. If done correctly, the Cloud allows data from every organization to access data from every other part. What’s more, the Cloud can place an analytics layer in front of the data—no one has to interpret raw data or bug a data science team to interpret the raw data. As such, the data isn’t available, but the best interpretations of the data are made available.

As a result, product design suddenly becomes a lot faster. Imagine the design team creating a 3D model of a design prototype and then sending it to the Cloud. The factory in Shenzhen downloads the model and creates a 3D metal printed version. They use this early interpretation to send feedback to the design team and create tooling for their production line. Meanwhile, the marketing team has an early look at the design and begins designing a campaign around it.

Increased functionality

Managing in the Cloud is advantageous as it gives product planning teams more flexibility than rigid tools like Excel. The Information Technology & Innovation Foundation reports that:

“Cloud-adaptive manufacturing firms generally exhibit higher average labor productivity compared to manufacturing firms that are not Cloud adaptive.”

The Economist Intelligence Unit indicates that 60% of manufacturers believe moving to the Cloud supports production processes, improves supply chain management, and enables better designing and prototyping. With the right platform, manufacturers can achieve infinite flexibility to run product walks against millions of buildable combinations—an impossible undertaking with spreadsheets.

Cloud security

Traditionally, manufacturers have held reservations about using the Cloud due to fears it can compromise their intellectual property. These are outdated fears that manufacturing enterprises are moving past. The old way of thinking that data is safer on-site than in the Cloud does not take into account that (most) Cloud providers maintain secure infrastructure that is resilient to attacks and provide disaster recovery contingency plans. Manufacturing Business Technology magazine referenced a quote by LNS Research driving this point home:

“By moving to the Cloud, security is usually enhanced rather than diminished as Cloud suppliers devote huge efforts to ensuring their underlying systems are as secure as possible and are constantly updated to react to potential threats. No individual manufacturer could devote such efforts, and they should focus on plant security working with their MES and plant software vendors to ensure maximum security and properly maintained systems. Do not get caught out by obsolete and vulnerable systems.”

When manufacturing embraces the increased functionality of the cloud and moves past security concerns, product design and production processes turn from a linear rigid process into an efficient, flexible operation.

Instead of completing a piece of work and throwing it over the transom to the next department, all departments work synchronously. Designs evolve in parallel, not in serial, resulting in a manufacturing process that becomes much better at handling increasingly complex product designs.

The Gocious Cloud platform

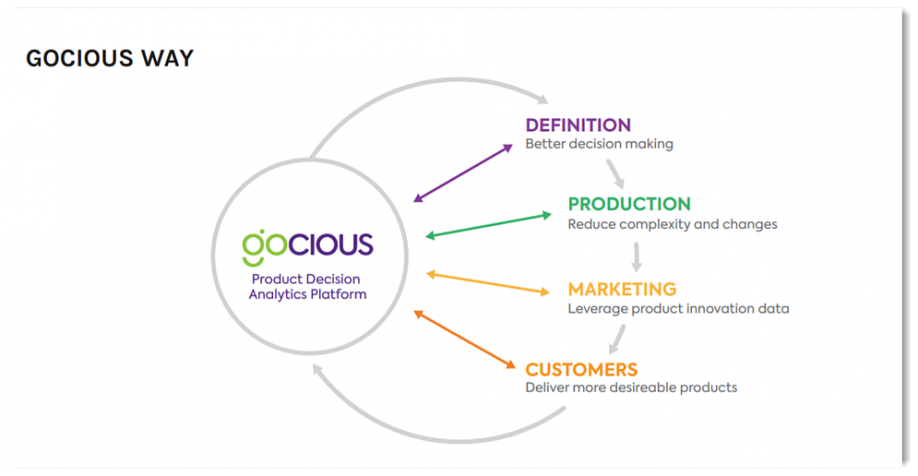

In our post A New Way to Analyze and Visualize Your Product Definition, we outline how our cloud-based product decision analytics platform improves how planning teams design and consider variants based on the best possible market outcomes.

The Gocious platform:

- Is optimized for flexible product design and planning

- Allows for capturing and rapid change in product constraints in addition to feature content

- Enables planning teams to run infinite what-if scenarios with weighted scoring

- Allows for seamless importing of existing xls data so teams can visualize data in ways never before possible

- Provides for secure and efficient collaboration across important stakeholders throughout the planning cycle

- Aggressively protects intellectual property through a hybrid security approach following both RBAC and ABAC, with Azure AD Authentication and encryption

We recently held a webinar tackling the issues that hinder product planners, designers, and engineers. We discuss our game-changing Cloud solution that helps teams get products to market more efficiently by taming the complex data that results with all the possible customer customizations. We encourage you to download the recording to learn more.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product