Adding robot systems to any stage in food and beverage manufacturing will help to increase throughput. Robots work consistently, around-the-clock allowing for dependable production rates. The latest innovations increase production flexibility and decrease changeover time.

Food and Beverage Survey Shows Increasing Output is a Major Driver for Integrating Robots

Contributed by | Motion Controls Robotics

Robotics in the food and beverage industry has been showing an average growth of 29% each year. This growth in robot integration is present from processing applications to end of line solutions like palletizing.

Motion Controls Robotics was curious to discover some of the main drivers for this increase in robotics and also explore what was holding some companies back. MCRI knows companies want an easy to use, cost effective robotic solution, but how does the definition of that change from company to company?

We developed a quick four question food and beverage survey to answer these questions:

*The survey participants could select more than one response.

1. What are your company’s main drivers for adding robotics?

- Increase output 69%

- Employee safety 68%

- Finding qualified/reliable workers 53%

- Packaging flexibility 42%

- Food sanitation 26%

We wanted to learn what was making companies want to add robotics. There is a lot of news about robotics taking jobs, but in most cases companies are really struggling with finding qualified and reliable employees. The other big driver we saw was the need to keep employees healthy and safe.

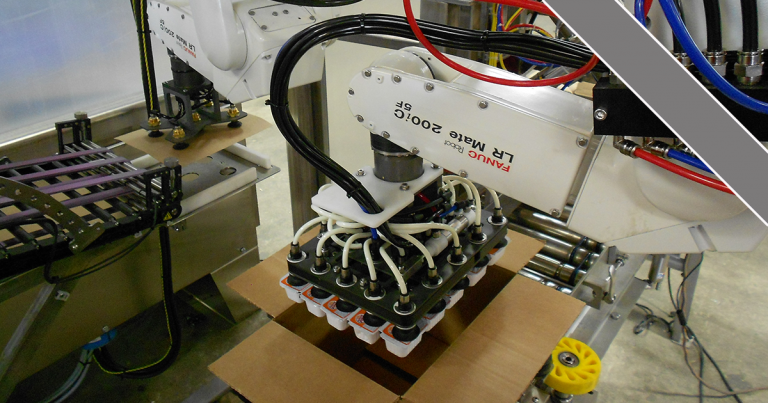

2. Which areas of your manufacturing process will benefit from robotics?

- Palletizing/Depalletizing 73%

- Primary Packaging/ Pick and Place 63%

- Processing 37%

- Secondary Packaging 32%

- SmartCart 5%

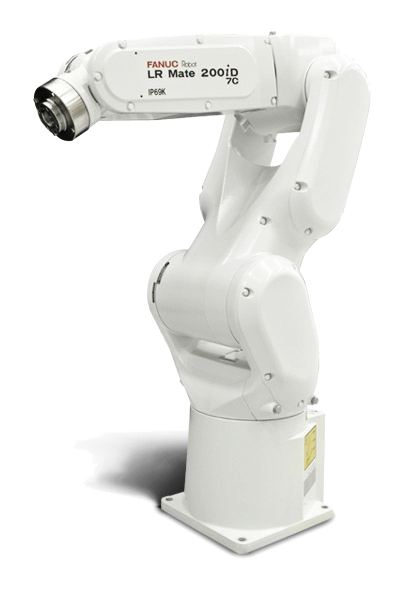

Adding robot systems to any stage in food and beverage manufacturing will help to increase throughput. Robots work consistently, around-the-clock allowing for dependable production rates. The latest innovations increase production flexibility and decrease changeover time. Product scanning allows companies to manage multiple products on one line. This helps companies fulfill packing and palletizing requirements from different customers and increase quality by eliminating errors in retail ready pallets.

With all these benefits, it is easy to see why the food and beverage industry is leaning toward robotics.

3. What are some of the worries your company has about integrating robots?

- Cost 68%

- Space 42%

- Lack of internal experience/knowledge 37%

- Complicated process 26%

- Finding the right integrator 16%

Even with all the benefits, making changes in a current process causes hesitation. The food and beverage industry professionals that participated in the survey named the biggest worries surrounding the idea of integrating robots.

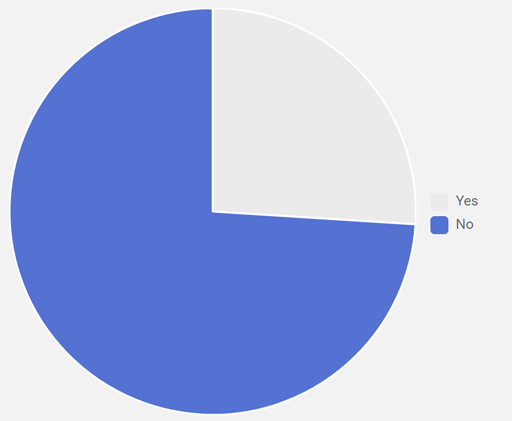

4. With growth in robotic use, not only in large but even small food manufacturing companies, does your company feel pressure to add robotics?

Food and Beverage Survey Comment

We see the future benefits as prices for robotics have dropped over the past 5-10 years. ~ food and beverage survey participant

Our sales people report that when they speak with customers one of the main reasons they state for adding robotics is, “everyone says we need to.” While the reason is promising because other manufacturers are benefiting from adding robot systems, it is not the reason to add robotics. You need to make sure you define a reason and goal for wanting to add robotics to your facility. If you do this, you will be able to see the huge benefit you get and the integrator can make sure that your issue is front and center when designing the system. Then someday you can tell someone they need to add robotics, but you can also explain why…

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product