What do I want to eat yesterday? Seems like a strange question. Yet IoT systems are architected to often ask very similar questions by aggregating a massive amount of data in a central repository where every so often a data scientist can evaluate and perhaps realize some insights that would have been best realized and responded to at the time the events were taking place at the edge.

Wind River's AXON Predict Analytics for VxWorks Enables IoT Analytics at the Edge

Kevin Konkos | Wind River

Reprinted with permission from the Wind River blog:

What do I want to eat yesterday? Seems like a strange question. Yet IoT systems are architected to often ask very similar questions by aggregating a massive amount of data in a central repository where every so often a data scientist can evaluate and perhaps realize some insights that would have been best realized and responded to at the time the events were taking place at the edge. To be clear, there are a number of valuable insights that can result from big data acquisition and analysis, and the outcomes of those insights should be considered in developing an IoT system. But there is yet another class of questions and insights that are best asked in real-time.

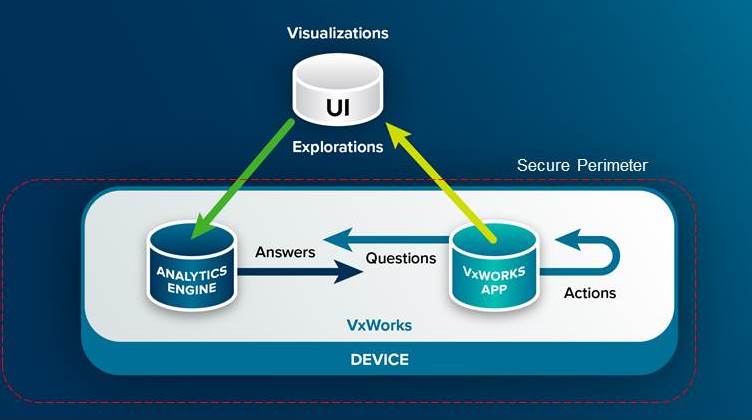

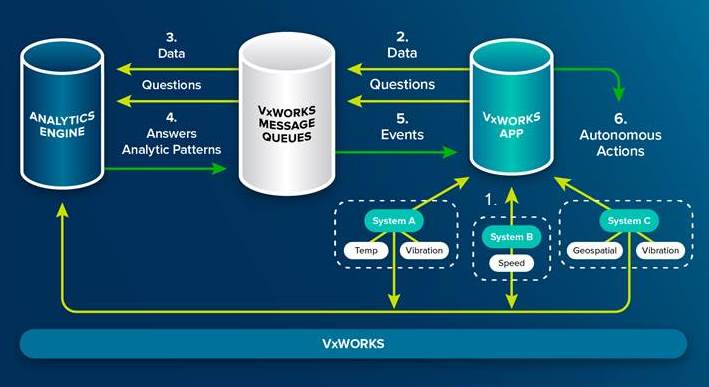

With this in mind, today, Wind River is expanding its VxWorks RTOS IoT product portfolio by introducing the new analytics product, AXON Predict Analytics for VxWorks, providing our VxWorks developers a way to embed on-device analytics into their applications to take advantage of predictive analytics, machine learning, and artificial intelligence. AXON Predict Analytics processes data without the need for cloud connectivity so our VxWorks developers using AXON Predict Analytics can now manage critical data at the edge of a network through visual edge analytics software and get autonomous responses in real time. Check out Figure 1.

Figure 1: AXON Predict Analytics for VxWorks architecture diagram

Best of Both Worlds – Stop the Hacking while Decreasing Costs

We all know that one reason IoT growth is being propelled is by the ever decreasing costs of network infrastructure, but for our customers those costs still do remain a key overall system cost driver that can be optimized with analytics at the edge. In addition, by utilizing increased on-device compute capabilities with our new analytics, our customers will get the added benefit of being able to limit unnecessary data propagation–decreasing the risk of their systems from being hacked. Which we all know is so important these days. Our new VxWorks analytics product provides these sharper insights and faster response times while managing both costs and security risks to help our customers improve their top and bottom lines. It’s the best of both worlds.

Real-time analytics at the edge – autonomous actions

Predictive Maintenance – Analytics Proves Its Value

While the use cases for AXON Predict Analytics are almost infinite, there is immediate impact and high business value for our customers in particular for predictive maintenance, self-healing, safety and security applications. According to an article on TNW, regular preventative maintenance on a 10 year-old air compressor worth $32,900 can extend the machine’s life for up to four years, resulting in a total saving of up to $6,359. Think about other expensive difficult to maintain devices and especially ones in locations with limited network connectivity such as drills on oil rigs, airplanes, military vehicles, wind turbines located in deserts, cranes, mining equipment, etc. For these types of complex disconnected devices, edge analytics can easily prove its value.

.jpg)

AXON Predict Analytics for VxWorks architecture diagram

We would love to talk to you about how our AXON Predict Analytics product can help you optimize your system costs and create business efficiency. Contact us and let us help.

For more information, check out the Product Overview and our website.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product