Lasers are compatible with any CNC machines, plotters and 3D printers and are easy to install.

Using the Endurance L-Cheapo 5.6 W (5600 mW) Semiconductor (Diode) Laser Operation

George Fomitchev | EnduranceLasers

Endurance is an authorized distributor of Robots Everywhere L-Cheapo lasers.

http://robots-everywhere.com/re_site_static/

Endurance upgrades lasers, make video, guidance and tutorials and does all sales and distribution process.

We’d like to tell you about possibilities, which a 5.6 W laser opens.

We have already written about relative features of the various diode lasers we tested in Endurance’s laboratory.

Now we’d like to tell about a more powerful diode laser, a 5.6 W L-Cheapo (Robots Everywhere production).

The laser looks

.jpg)

It does differ much from a 2.1W and a 3.5 W lasers.

Its main difference is inside. It has a more efficient cooling system and a more powerful solid-state diode. Another difference is the current strength demand. It draws 3-4 A, while a 2.1 W and a 3.5 W lasers need only 1.7- 2 Ð with the same voltage of 9-12 v.

Our tests showed that the laser is able to work 48 hours non-stop or perhaps even more.

Spotlights of the 5.6 W laser

The ability to cut 8 mm plywood and 5 mm acrylic allows solving a lot of customers’ practical tasks.

It should be mentioned that the same materials in different environmental conditions (temperature, humidity, etc.) might require different parameters of cutting. The color and transparency of the material matter.

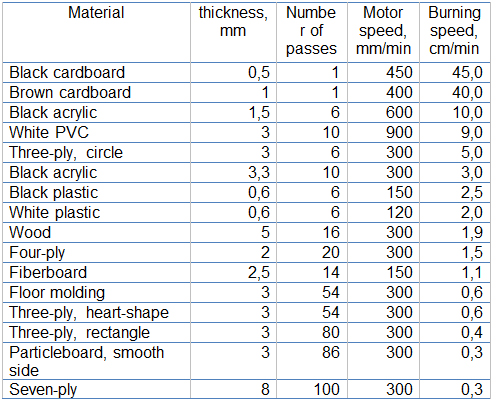

The table below shows the tested materials and cutting parameters of the 5.6 W diode laser.

Cutting parameters

Samples of the cat image we cut during the experiment.

It should be specified that these data are approximate, as there are many varieties of material.

We used a few kinds of three-ply. Though all ply samples looked absolutely the same we obtained different results.

You can not just cut plywood, wood and acrylic with the 5.5W laser but you can also make work pieces for bread boards (on copper-plated glass fiber plastic) and for aluminum engraving.

The laser fits not just for cutting but for engraving as well. We wrote about it in our early articles.

Lasers are compatible with any CNC machines, plotters and 3D printers and are easy to install.

Enjoy your work!

|

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product

George I Fomitchev

George I Fomitchev