Talking RAPID + TCT with Joe Wilkers of Mazak

Well be showcasing our new VC-500 AM, a full five-axis HYBRID Multi-Tasking machine that offers both additive and subtractive manufacturing and Mazaks DONE IN ONE® part processing capability."

Talking RAPID + TCT with Protolabs

Well be showcasing some of the most unique parts weve printed in a variety of 3D printing processes and materials over the years, including the latest addition to our 3D printing service offering, HPs Multi Jet Fusion.

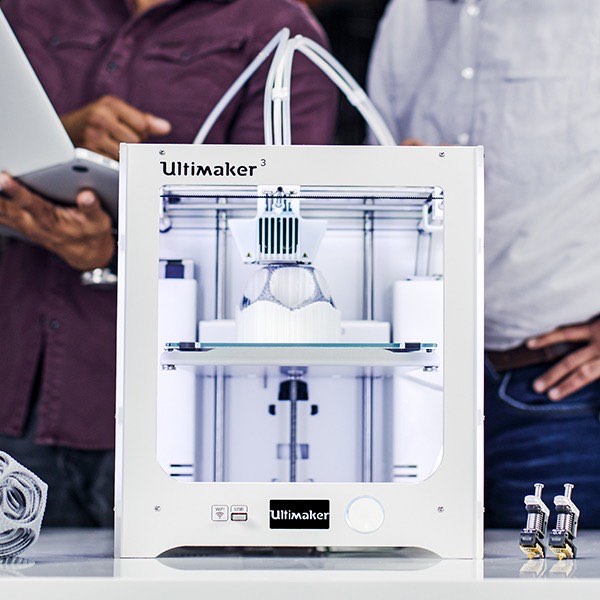

Talking RAPID + TCT with Ultimaker

Ultimaker is committed to offering a complete 3D printing solution for our professional user base, from hardware to software and materials, and well use this opportunity to demonstrate our latest technology.

Records 16 to 18 of 18

Featured Product

MOTION CONTROLLERS FOR MINIATURE DRIVES AND MICRODRIVES

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new Motion Controller is ideal for integration in equipment manufacturing and medical technology applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to approx. 100 W and is suitable for DC-motors with encoder, brushless drives or linear motors.

Manufacturing and Automation - Featured Company

FAULHABER MICROMO

Since 1961, FAULHABER MICROMO has partnered with OEMs to deliver high precision, high performance, custom micro motion system solutions to markets such as medical, robotics and automation in North America. FAULHABER MICROMO's tradition of innovation started decades ago in Germany. The groundbreaking invention of the FAULHABER coreless winding started it all for a market that produces millions of motors today.

How can the FAULHABER MICROMO team help you deliver your next innovation to market first?

Learn more about MICROMO's solutions for the most demanding applications, our diverse motion products and technologies, online ordering, Engineering and R&D teams, Clean Room Assembly, Machining Center and other services at our Clearwater, FL facility at www.micromo.com.