Basics of 3D Printing Simulation: Answering Key Questions

3D printing, or additive manufacturing, builds objects layer by layer. To ensure success, simulation is crucial. It lets us virtually test and optimize the printing process, predicting issues like warping and cracking caused by thermal stress. By catching these problems early, we can prevent failed prints, save material, and produce high-quality parts efficiently.

However, accurately simulating this process is complex. It involves intricate physics, requiring precise data on material behavior and rapid temperature changes. The detailed geometries of 3D-printed designs and the high computational power needed for accurate analysis also pose significant challenges, making simulation a demanding task.

In this blog, we'll dive deeper into 3D printing simulation. We'll explore how Finite Element Analysis (FEA) improves accuracy and discuss key considerations for thermal and mechanical analysis. You'll learn about advanced meshing techniques and get an overview of common simulation software like Abaqus and ANSYS, along with the steps needed to perform a successful simulation.

1. Why is simulation considered crucial for successful 3D printing?

Simulation plays a vital role in additive manufacturing by allowing engineers to virtually test and optimize the printing process before physical production. This helps predict and prevent potential issues such as material warping, bonding failures, and geometric inaccuracies caused by thermal stress and other factors. By identifying and addressing these problems early on, simulation reduces the likelihood of print failures and material waste, ultimately saving time and costs while ensuring the production of high-quality, reliable parts, especially in critical industries like aerospace and medicine.

2. What are the primary challenges in accurately simulating 3D printing processes?

Simulating 3D printing presents several key challenges. The process involves complex multi-physics interactions, requiring accurate input of thermal properties, material behavior, and even particle geometry. Rapid temperature changes can lead to defects like warping and cracking, making precise prediction difficult. The intricate geometries of many 3D-printed designs, including overhangs and lattice structures, demand advanced simulation algorithms. Furthermore, the variability in material properties and the high computational resources needed for detailed simulations add to the complexity.

3. How does Finite Element Analysis (FEA) enhance the accuracy of 3D printing simulations?

Finite Element Analysis (FEA) is a crucial technique in 3D printing simulation because it allows for the detailed modeling of thermal, structural, and material interactions. FEA works by dividing a complex 3D-printed object into smaller, manageable elements, enabling precise analysis of how each part behaves under specific conditions. This method helps predict and solve complex issues like warping and residual stress by considering the anisotropic behavior of materials in intricate internal structures. By comparing simulations with real-world structures and balancing accuracy with computational practicality, FEA bridges the gap between theoretical modeling and actual 3D-printed outcomes.

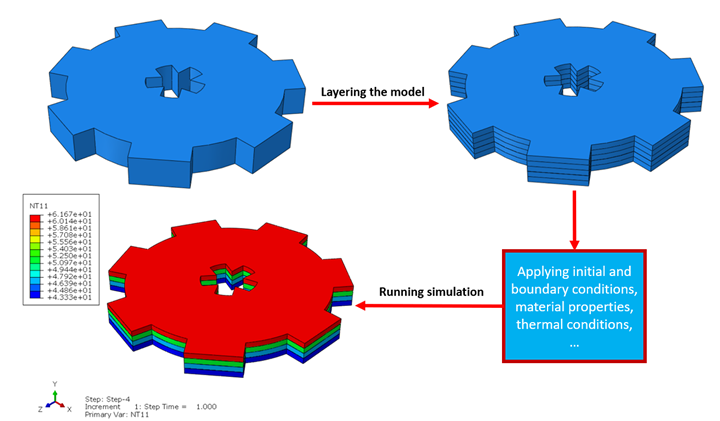

Figure 1: BASICS OF 3D PRINTING SIMULATION

4. What are the key thermal analysis considerations in additive manufacturing simulation?

Thermal analysis in 3D printing simulation focuses on understanding heat transfer within the melting zone and its surroundings. This involves considering conduction, convection, and radiation, with conduction being the most critical. Advanced models like the Goldak heat source are used to accurately predict temperature distribution, especially in metal printing processes like Laser Powder Bed Fusion (LPBF). Factors such as laser scan speed, layer thickness, build orientation, and cooling system design are optimized based on thermal analysis insights, helping to minimize residual stresses, distortions, and defects like micro-cracks and poor layer adhesion.

5. How is mechanical stress and strain analyzed in additive manufacturing simulation to ensure structural integrity?

Mechanical stress and strain analysis in 3D printing simulation involves using advanced equations like the three-dimensional extension of Hooke's Law and finite element methods to examine material behavior under load. This analysis considers the anisotropic properties of 3D-printed parts arising from print directionality and layer-by-layer construction. Simulation software models infill patterns and material engineering parameters to predict stress distribution and deformations. Techniques like plasticity models are used for repeated loading scenarios, allowing designers to optimize print orientation, infill patterns, and material selection to enhance the performance and durability of the final part.

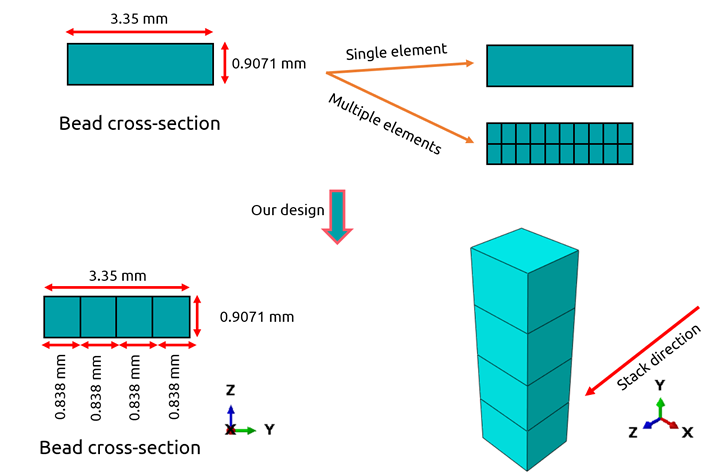

6. Why are advanced meshing techniques important for accurate additive manufacturing simulation results?

Advanced meshing techniques are essential for capturing the precise behavior of 3D-printed parts under various conditions. Methods like adaptive meshing refine the mesh in areas of high stress or temperature gradients, while mesh coarsening reduces element density in uniform regions, balancing accuracy with computational efficiency. Hybrid meshing combines different element types to handle complex geometries effectively. Mesh convergence studies are conducted to ensure the mesh is sufficiently detailed for reliable results. These techniques allow engineers to accurately predict deformations, optimize part geometry, and reduce the need for costly reprints.

Figure 2: A sample of meshing calculation

7. What are the key features and applications of Abaqus, ANSYS, and Simufact in the context of additive manufacturing simulation?

Abaqus is a powerful software known for its ability to handle complex thermomechanical problems, phase changes, and large deformations, making it ideal for industries like aerospace and automotive. It offers high-fidelity modeling through Python scripting, subroutines, and the user-friendly AM Modeler plug-in, supporting techniques like FDM, SLA, and LPBF.

ANSYS is another robust platform used for thermomechanical analyses in methods like SLM and DMLS. It excels in coupling heat flow with stress-strain analysis to predict residual stresses and distortions, supports advanced material models, and offers features like Element Birth and Death for simulating layer deposition.

Simufact (by MSC/Hexagon) is a specialized solution primarily focused on simulating metal-based additive manufacturing processes like SLM and DMLS. It accurately predicts residual stresses, distortion, and melt pool behavior using a layer-by-layer approach and supports various scan strategies. While its core focus is on metals, recent versions include basic capabilities for polymers.

The choice of software depends on factors like cost, accuracy requirements, project complexity, industry-specific needs (e.g., aerospace often favors Abaqus or ANSYS for high-fidelity), and material focus (Simufact is strong for metals).

8. Sources for Learning 3D printing simulation

CAE Assistant: Specialized courses on Additive Manufacturing Simulation using Abaqus.

One standout feature of CAE Assistant is its focus on specialized and practical courses, such as 3D printing simulation in Abaqus. These courses incorporate real-world projects and provide detailed guidance, making learning more effective for engineers. Additionally, its robust support services and tools, like custom plugins tailored for specific needs, distinguish it from other learning platforms.

The CAE Assistant 3D printing tutorial covers two methods for additive manufacturing simulation:

- Python for Abaqus: Tutorials on scripting for custom analysis.

- AM Modeler Training: Courses on using specialized 3D printing plugins.

Studying Official Abaqus Documentation:

Dassault Systèmes Documentation: Official guides including mechanical and thermodynamic analyses.

Abaqus Benchmarks: Validated analyses for specific simulations.

Webinars and Conferences:

Dassault Systèmes Events: Free specialized webinars.

NAFEMS: Renowned engineering conferences focusing on numerical simulations.

Industrial Projects:

LinkedIn Learning: Practical projects with real-world applications.

Academic Publications: Research papers focusing on industrial Abaqus applications.

YouTube Videos

You can search in YouTube with the keyword “3D printing simulation” or its variation and watch the top videos in top channels regarding the 3D printing simulation in Abaqus or any other software you need.

9. How do you typically perform a 3D printing simulation using software like Abaqus or ANSYS?

The general process for performing a 3D printing simulation involves several steps that are consistent across different software:

Model Creation: First, the 3D model of the part is created using CAD software or within the simulation environment itself.

Slicing: The 3D model is then virtually sliced into thin layers, mimicking the layer-by-layer construction of the 3D printing process.

Import and Meshing: The sliced model is imported into the simulation software (e.g., Abaqus, ANSYS), where a mesh is generated. The mesh divides the model into discrete elements for analysis.

Defining Properties and Conditions: Material properties (thermal, mechanical), boundary conditions (constraints, supports), and thermal conditions (heat sources, ambient temperature) are defined based on the specific 3D printing process being simulated. For layer-by-layer activation, techniques like Python scripting, subroutines (in Abaqus), or Element Birth and Death (in ANSYS) are used to activate material layer by layer.

Setting Up the Analysis: The type of analysis (e.g., thermal, structural, thermomechanical) and simulation parameters (e.g., time steps, convergence criteria) are configured.

Running the Simulation: The simulation is executed, and the software solves the defined equations based on the inputs.

Post-processing and Analysis: After the simulation, the results (e.g., temperature distribution, stress, strain, deformation) are analyzed to predict the behavior of the 3D-printed part and identify potential issues. This allows for optimization of printing parameters and design modifications.

10. Recap

This article provided a comprehensive overview of additive manufacturing simulation, which involves virtually testing and optimizing the 3D printing process. The author began by explaining the critical role of simulation in preventing common issues like material warping and cracking, highlighting how this practice reduces print failures and waste while ensuring high-quality parts.

The discussion then delved into the technical complexities of accurate simulation, such as the need to account for rapid temperature changes and intricate material behaviors. The article explained how Finite Element Analysis (FEA) is used to model these complex interactions and covered key considerations for both thermal and mechanical analysis. The importance of advanced meshing techniques for achieving reliable results was also emphasized.

Finally, the author outlined the features of popular simulation software like Abaqus, ANSYS, and Simufact, and described the typical steps involved in a 3D printing simulation workflow. In conclusion, the article underscored the vital role of simulation in achieving optimized and dependable outcomes in additive manufacturing.

Featured Product