Adapting to Change: How CPQ Software Is Shaping the Future of Custom Manufacturing

As the backbone of the U.S. economy, the manufacturing industry makes up more than 13.6% of the global workforce. The strength of this sector is vital to America's economic growth and innovation across industries. However, the industry is at a pivotal crossroads. The rapid pace of digital transformation—spurred by automation, artificial intelligence (AI), and shifting supply chain dynamics—requires manufacturers to adapt quickly to remain competitive. Adding to these pressures is heightened market volatility, which has introduced new complexities, disrupted global trade flows, and increased operational costs, further threatening manufacturers' ability to maintain their global edge. Our latest research confirms that digital maturity—not company size—now defines the winners.

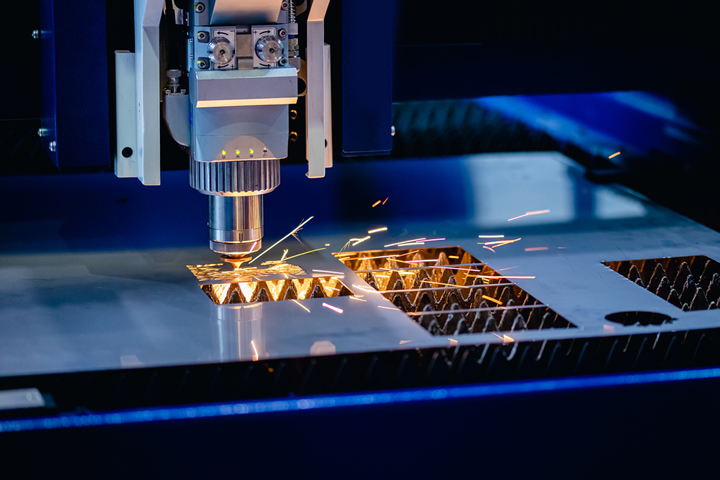

In response, companies are exploring custom manufacturing, with the market expected to grow to $1.35 trillion by 2031. Custom manufacturing allows organizations to develop products to meet their specific needs, enabling them to navigate rising costs and supply chain disruptions more effectively while preserving their competitive edge. This shift toward personalized production methods signals a broader trend in today’s marketplace, where companies increasingly seek greater control over quality, costs, and supply chain stability.

CPQ Software: The Game-Changing Solution for Custom Manufacturing

As part of the broader digital thread that connects engineering, manufacturing, and service, CPQ sits between PLM, CRM, and ERP, translating engineering intent into revenue. As customer demand for personalized products grows, businesses are turning to configure, price, quote (CPQ) software to enhance their custom manufacturing capabilities. This software allows manufacturers to design products based on specific customer needs, provide real-time pricing updates, and address supply chain challenges—key factors in maintaining a competitive edge. Based on our recent report, Smart Manufacturing 2025: Trends Shaping the Digital-First Era and Beyond, which surveyed 500 decision makers in CPQ, PLM, engineering modeling, and simulation software across the United States and Germany, 69% of manufacturing organizations plan to increase their investment in CPQ software this year—underscoring its rising strategic importance across the industry.

CPQ software addresses the growing demand for customized solutions by enabling manufacturers to build products to exact customer specifications, streamlining the customization process while significantly enhancing customer satisfaction. By meeting these unique demands, manufacturers not only foster customer loyalty but also strengthen their market positions.

In addition to product configuration, CPQ software automates the quoting process with real-time data, cutting errors and delays by 36%, accelerating the sales cycle and improving the overall customer experience by 35%. The automation of critical workflows—such as configuration, pricing, and quoting—improves operational efficiency, provides better control over pricing strategies, and enables more precise margin management, offering a sustained competitive edge.

While the initial investment in CPQ software can be significant, the return on investment (ROI) is substantial. Manufacturers have reported a 35% increase in revenue often within the first 12 months following implementation. In the fast-paced world of custom manufacturing—where speed, accuracy, and responsiveness are critical amid rising costs and volatile market conditions—CPQ software equips sales teams to generate and deliver precise quotes quickly, boosting both customer satisfaction and measurable revenue growth.

Overcoming Implementation Challenges

While CPQ software is proving to be a game changer, many organizations face implementation challenges that prevent them from fully unlocking its potential. Training team members on new software is a hurdle, with 33% of manufacturers citing it as a major obstacle. The steep learning curves, extended setup times, and potential disruptions to daily operations can make it difficult for businesses to achieve a quick return on investment.

However, companies can adopt a phased implementation strategy that allows them to gradually integrate CPQ software into their workflows, minimizing disruption. Investing in training programs, such as role-based learning, interactive tutorials, and ongoing support, ensures that team members are well-prepared to use the software effectively. Businesses that provide training at each stage of implementation can reduce the learning curve, foster confidence among users, and accelerate the adoption process, ultimately leading to a smoother transition and faster realization of the software's benefits.

Organizations have also identified maintaining data privacy and security (32%) and ensuring data accuracy (32%) as critical areas of concern. Leveraging a Software as a Service (SaaS) platform enables organizations to benefit from advanced cloud security protocols, regular vulnerability assessments, and strong disaster recovery systems to ensure top-tier data protection and keeps customers on the latest release without extra IT effort. Additionally, real-time data synchronization within the SaaS platform helps minimize the risk of manual errors, ensuring accurate configurations, bills of material, routings, and quotes with every transaction.

Looking Into the Future—AI and Advanced Analytics

The next evolution of CPQ moves from rule-based to learning-based configuration. As technology continues to advance, CPQ software and its applications will continue to evolve, with AI and advanced analytics playing key roles. By 2050, engineering and manufacturing professionals predict that AI-driven recommendations and advanced analytics will significantly impact the industry, with 37% of professionals identifying AI as a major driver of change and 30% citing advanced analytics.

Machine learning is already reshaping CPQ software, enabling it to learn from data to become smarter and more efficient over time, leading to increasingly accurate AI-driven recommendations. Enhanced analytics within CPQ platforms will provide manufacturers with deeper real-time insights, more precise trend analyses, and detailed performance metrics. This powerful combination of AI and advanced analytics will empower organizations to make more informed, data-driven decisions, ultimately driving greater operational efficiency and strategic growth.

Overall, CPQ software is transforming the manufacturing landscape by enabling companies to offer more personalized solutions, optimize production processes, and stay competitive. The integration of AI and advanced analytics will further enhance these capabilities, making CPQ software an indispensable tool for manufacturers in the years to come. By fully embracing the potential of CPQ software, manufacturers can ensure greater flexibility, improved customer satisfaction, and sustained growth in an increasingly competitive market.

Featured Product