Apple Wins a Patent for a Future 3D Printing System that works with Augmented Reality and AR Glasses

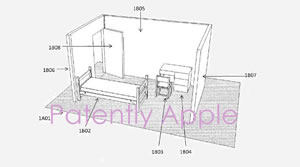

Patently Apple: Apple's newly granted patent covers their invention relating to a method for instructing a 3D printing system comprising a 3D printer and to a 3D printing system. The present disclosure is further related to a method for instructing a device communicating with a 3D printing system comprising a 3D printer.

Patently Apple: Apple's newly granted patent covers their invention relating to a method for instructing a 3D printing system comprising a 3D printer and to a 3D printing system. The present disclosure is further related to a method for instructing a device communicating with a 3D printing system comprising a 3D printer.

Apple notes that there's a need for further applications of a 3D printer, such as extending an existing real object through printing additional objects onto a surface of the existing object by using a 3D printer. One challenge in such applications may be where to place the existing object or how to adjust one or more print heads of the printer such that the additional objects will be printed onto a desired area of the surface of the existing object in order to build a composed object satisfying a pre-determined alignment between the additional objects and the existing object.

Apple further notes that there isn't any prior art that solves the problem of using a 3D printer to print at least one object onto a desired surface area of an existing object or a part of the existing object in order to build a composed object satisfying a pre-determined alignment between the at least one object and the existing object. Full Article:

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product