MakerBot is laying off a third of its staff, narrowing focus under Stratasys

Shawn Knight for TechSpot: 3D printing ordinary household goods may be able to save users a bit of coin but consumers aren’t buying it – literally – and that’s forcing one company to downsize its workforce.

Shawn Knight for TechSpot: 3D printing ordinary household goods may be able to save users a bit of coin but consumers aren’t buying it – literally – and that’s forcing one company to downsize its workforce.

In what is becoming a common occurrence, MakerBot recently announced additional restructuring that’ll see the company shed 30 percent of its staff.

CEO Nadav Goshen said greater focus on long-term goals is key to their success and to get there, they must reduce the “pressure and distraction” of chasing short-term market trends and focus on their core products.

The executive didn’t say which divisions would be hit hardest, nor do we know exactly how many employees are being let go although TechCrunch estimates the figure is probably between 80 and 100.

Specifically, MakerBot will be integrating hardware and software product development under one team that’ll be led by VP of Engineering Dave Veisz. Current Director of Digital Products, Lucas Levin, is also being promoted to VP of Product, we’re told, and will lead product management across hardware and software. Cont'd...

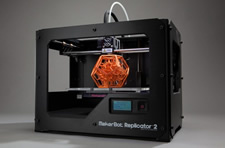

Featured Product