The Message Queueing Telemetry Transport protocol (MQTT), utilizes a client-server publish-subscribe architecture for data exchange. MQTT is useful in machine-to-machine and Industrial Internet of Things (IIoT) environments where bandwidth is typically limited.

The Role of MQTT in Industrial Automation: Enhancing Connectivity and Efficiency

Article from | CIMON Automation

Overview

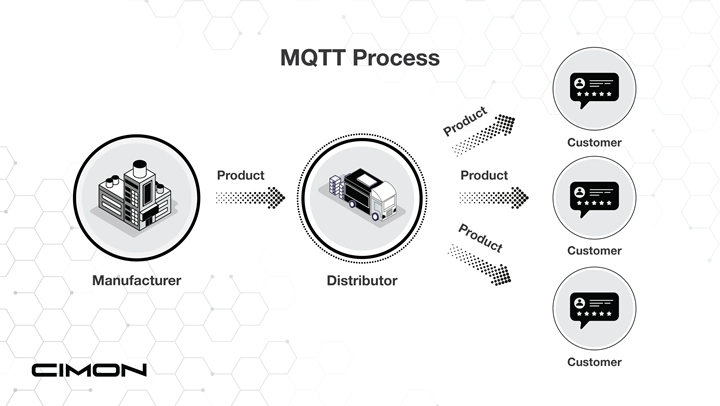

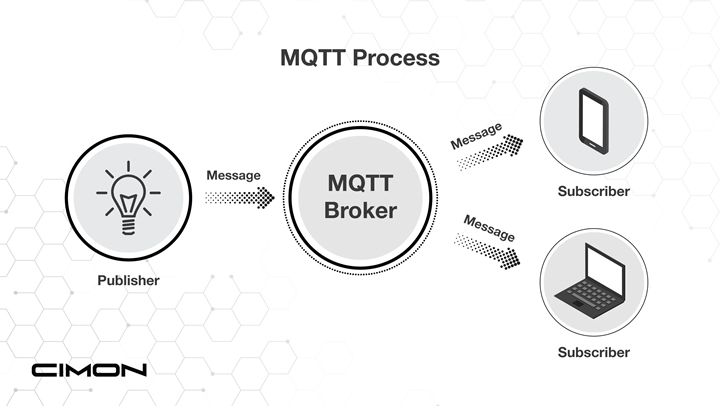

The Message Queueing Telemetry Transport protocol, standardly referred to as MQTT, utilizes a client-server publish-subscribe architecture for data exchange. MQTT is useful in machine-to-machine and Industrial Internet of Things (IIoT) environments where bandwidth is typically limited. This protocol can be described as “lightweight” because it is not resource-intensive when used. This is accomplished by incorporating a third party in the communication relationship, a broker, which acts as a data transfer buffer. Traditionally, field devices experience a bandwidth burden when publishing data to multiple clients, and brokers help conquer this, similar to how distributors assist in the manufacturer-customer model.

Features

The main features of MQTT are its use of topics and subscriptions. Messages contain topics that act as a channel or directory that are published and subscribed to. Users utilize a subscription to obtain the topic message that the user is interested in receiving. Clients can subscribe to more than one topic; conversely, topics can have multiple subscribers. MQTT also has a broker that keeps track of what the user is subscribed to and will send the topic message upon update. A way to think about this would be a manufacturer-distributor-customer model. MQTT also supports encryption to keep communication between clients and the broker secure.

The above image exemplifies how the MQTT model would look in the context of a manufacturer and a distributor. The field device (manufacturer) will send the information to a broker (distributor) when it is updated and disperse it to subscribers (customers). The reasoning is to take the burden off the publisher and let the broker handle the distribution of topics.

Role in Industrial Automation

MQTT overcomes the low bandwidth limitation in most industrial automation facilities by connecting machines and sensors to edge-of-network or gateway devices that behave as an MQTT broker. In this setting, MQTT can improve efficiency by allowing for real-time monitoring of systems and the control of processes and reducing downtime for industrial automation. Using MQTT provides ease of scalability within industrial automation as well; it allows new devices to join the network quickly by only needing to subscribe to the relevant topics. MQTT allows quick real-time communication within industrial automation facilities that utilize SCADA and limits the resource usage.

How does CIMON use it?

CIMON has the MQTT protocol available on their nXT/eXT HMIs that utilize the designer software Canvas. Canvas allows users to set up an HMI to become a publisher for a topic and send messages to a broker. For Canvas specifically, the MQTT protocol will send tag data in a JSON format to broker devices.

Conclusion

MQTT is a lightweight protocol primarily used for IIoT and machine-to-machine applications. The subscribe-publish model using brokers allows easy data exchange between the client and server. MQTT not only provides for the scalability of a project but also allows for less resources and bandwidth to be used to obtain real-time updates concisely.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product

.jpg)