Industry 4.0 is driving major gains in efficiency, automation, and innovation. But there's a flip side: That progress depends on fast, secure, always-on connectivity. Manufacturing, in particular, is an interesting case study.

Prioritizing Network Investment in Manufacturing

Prioritizing Network Investment in Manufacturing

Q&A with Max Clauson, SVP of Network Connectivity | Zayo

Tell us a little bit about yourself and your role with Zayo.

I’ve been in telecom for more than two decades, and at Zayo, I lead our Network Connectivity team. That work gives me a front-row seat to the real challenges businesses face and the role smart, scalable network solutions play in keeping them connected, secure, and resilient.

You've pointed out that while Industry 4.0 holds great promise, it also raises important concerns. What do you mean by that?

Industry 4.0 is driving major gains in efficiency, automation, and innovation. But there’s a flip side: That progress depends on fast, secure, always-on connectivity. Manufacturing, in particular, is an interesting case study because we can still find so many examples of legacy systems and outdated infrastructure. But accelerated digital transformation has forced the industry to adopt advanced applications, like edge computing and real-time analytics, which naturally introduces complexity and risk to the network infrastructure.

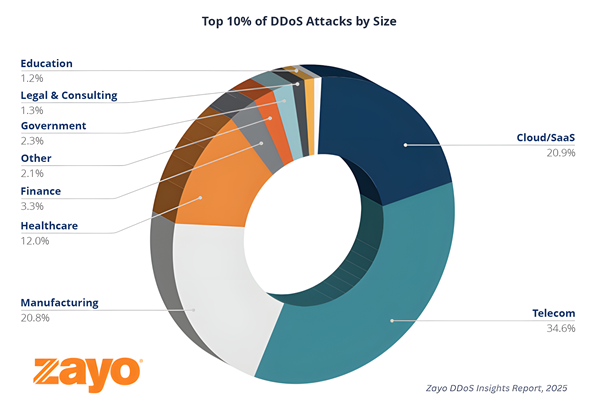

The rising complexity is also creating new vulnerabilities. In fact, in our recent DDoS Trends Report, we saw a 257% increase in the size of attacks targeting manufacturers, which reflects just how much the attack surface has expanded.

These huge — and necessary — advancements in the manufacturing industry are accompanied by even greater challenges, both from an infrastructure and security standpoint. The technology is exciting, but the underlying infrastructure has to catch up fast, or manufacturers risk being left behind.

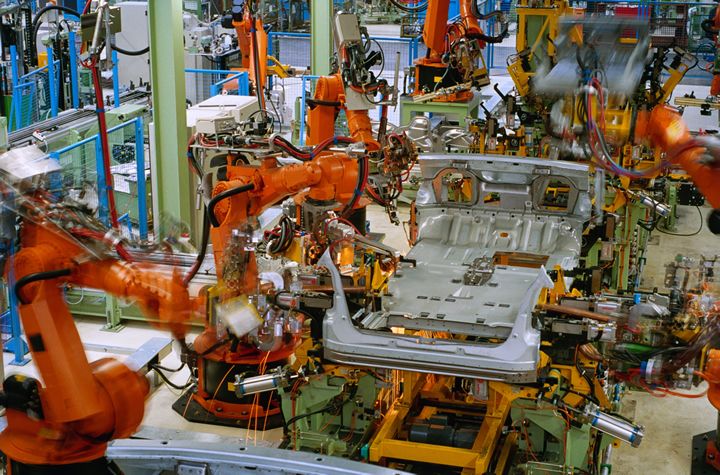

How do AI, robotics, and IoT technologies strain existing network systems inside smart factories?

These technologies generate massive amounts of data and require incredibly low latency to function properly. Think about a robotic arm on a production line: it needs to respond in real time. Or an AI model monitoring quality control: it’s constantly processing sensor inputs to make split-second decisions. Add thousands of IoT devices to the mix, and you’ve got a network that’s under constant pressure. If the infrastructure wasn’t designed to handle that volume and speed, you’ll start to see lag, breakdowns, and a lot of frustration on the factory floor.

We also see the growing network challenges presented by edge computing. Those IoT devices are not only connected to the network, but they run their own computes and generate discrete data that needs storage in the Cloud, which also requires bandwidth and continuous network access. It’s a holistic ecosystem that requires more bandwidth — especially agile and scalable bandwidth — in new places, and it’s only going to continue expanding.

How can a breakdown in network infrastructure halt production in a high-tech facility?

Today, in smart factories, everything runs on the network, from machine controls and automation systems to inventory tracking and even safety protocols. If that network goes down or slows to a crawl, you’re not just losing connectivity, you’re stopping production. Machines can’t operate, data doesn’t flow, and decisions stall. It’s like trying to run a modern factory on a dial-up internet connection. Beyond the immediate disruption, there’s the financial cost of downtime and the potential hit to customer trust. That’s why resilience, through redundant paths, diverse routing, and edge connectivity, is so important.

You mentioned earlier that your report found a 257% increase in DDoS attack size targeting manufacturers. What’s driving that surge?

It’s really a case of digitalization outpacing security. Manufacturers are moving fast to modernize. They’re automating processes, connecting equipment, layering in real-time analytics — all of which is building complexity for network environments. But that same sense of urgency hasn’t carried over to securing those environments. Bad actors are taking advantage of these vulnerabilities, and DDoS attacks, specifically, are attractive because they are relatively easy to execute and can cause major disruption, especially in high-stakes, always-on environments like a smart factory. As IoT devices proliferate and connectivity grows, so does the attack surface. Attackers are getting bolder, knowing that even a short disruption can lead to significant downtime and revenue loss.

What should manufacturers be doing today to future-proof their operations against both downtime and cyberattacks?

Future-proofing starts with rethinking the network — not just for today’s demands, but for what’s coming next. That means higher capacity, lower latency, and more resilience at the foundation. For most manufacturers, that means working with partners who understand how to build and manage networks that meet evolving demands, including investing in fiber, designing for redundancy, and making sure connectivity reaches all the way to the edge of the operation. But, performance isn’t the whole picture. Visibility and security need to be part of the equation from day one. DDoS mitigation, network observability — these aren’t nice-to-haves anymore; they’re critical to staying ahead of threats before they interrupt production.

In my experience, the companies that get this right aren’t doing it alone. They’re leaning on those partners who understand the unique challenges of Industry 4.0 and can build infrastructure that scales as network demands grow. That’s where real operational resilience comes from.

How should manufacturing leaders prioritize network investments alongside automation and AI tools?

Network infrastructure can’t be an afterthought. It needs to scale with automation and AI. I’ve seen manufacturers invest in smart tools, only to realize their network can’t support the speed, volume, or reliability those tools demand.

The best approach is to treat the network as a core part of your innovation stack. That means investing in high-capacity, low-latency connectivity, building in redundancy, and ensuring visibility across the factory floor. The smartest leaders think holistically and see the network not just as plumbing, but as a platform for growth.

What trends do you predict in how bandwidth will need to be delivered or how it will be consumed by customers over the next several years?

We’re seeing a real shift toward more self-service, on-demand network models. Enterprise customers increasingly expect bandwidth to be as flexible and easy to manage as cloud services. It’s not just about how bandwidth is delivered. It’s about giving customers control over how they procure, manage, and scale it, all through simple, digital interfaces.

That’s making it easier to right-size bandwidth for different needs, whether it’s turning up capacity temporarily for a specific project or scaling down during quieter periods. Customers are looking for the same agility they’ve come to expect from cloud providers like AWS, where resources can be adjusted on demand. Whether they actually flex usage or just appreciate the visibility and control remains to be seen, but the appetite for transparency, flexibility, and simplicity is clear.

Max Clauson is a commercially focused leader with a proven track record of accelerating value creation through strategic growth initiatives, encompassing both organic and inorganic strategies. Currently serving as Senior Vice President of Network Connectivity at Zayo Group, Clauson leads initiatives to enhance and expand the company's global communications infrastructure. Clauson's 8+ year tenure at Zayo spans multiple leadership roles, including President of Sales and President of Transport Services. Before joining Zayo, he served as the Director of Market Management at Level 3 Communications, overseeing revenue base management and incremental growth opportunities for the Cable, Carrier, and VSP segments. Clauson holds an MBA from the University of Colorado Boulder's Leeds School of Business and a BA in Economics from Bates College.

Max Clauson is a commercially focused leader with a proven track record of accelerating value creation through strategic growth initiatives, encompassing both organic and inorganic strategies. Currently serving as Senior Vice President of Network Connectivity at Zayo Group, Clauson leads initiatives to enhance and expand the company's global communications infrastructure. Clauson's 8+ year tenure at Zayo spans multiple leadership roles, including President of Sales and President of Transport Services. Before joining Zayo, he served as the Director of Market Management at Level 3 Communications, overseeing revenue base management and incremental growth opportunities for the Cable, Carrier, and VSP segments. Clauson holds an MBA from the University of Colorado Boulder's Leeds School of Business and a BA in Economics from Bates College.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product