In this interview, the co-founders of 3D People Sasha Bruml and Felix Manley, talk about what motivated them to launch the company in 2017 and how they stay motivated to keep delivering and continue adding value for their customers.

Launching of a 3D Printing Company

Q&A with Felix Manley & Sasha Bruml, Founders | 3D PEOPLE

Utilising industrial additive manufacturing (AM) processes, specifically polymer powder bed fusion (PBF) technologies, 3D People has established a manufacturing service that has garnered a reputation for quality and efficiency. With a suite of both selective laser sintering (SLS) and MultiJet Fusion (MJF) systems operated in house, the company delivers on its promises while also setting itself apart in the 3D printing service bureau market in some key ways. The 3D People team has a wealth of experience across the additive processes themselves as well as the ecosystem around them. Using both their software and hardware expertise, the team has introduced the most efficient ordering system available as well as invested heavily on a wide range of finishing options for parts that range from 1-offs to thousands of production parts.

In this interview, the co-founders of 3D People Sasha Bruml and Felix Manley, talk about what motivated them to launch the company in 2017 and how they stay motivated to keep delivering and continue adding value for their customers.

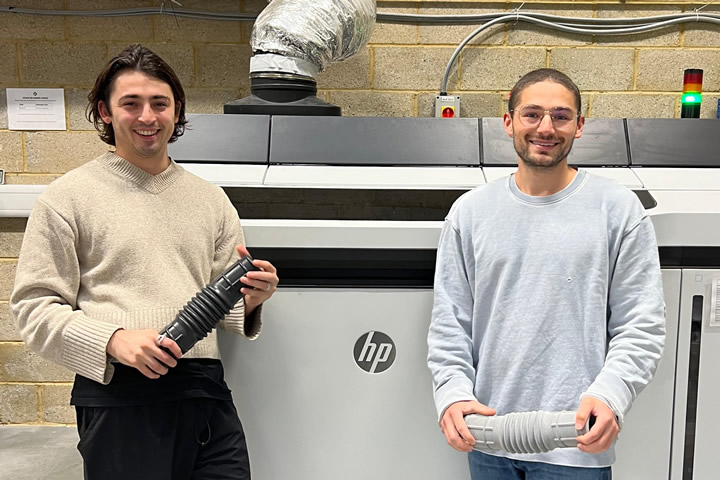

Felix Manley (left) and Sasha Bruml, co-founders of 3D People

Can you tell us a little about your backgrounds, your introduction to 3D printing and additive manufacturing and what excited you about this technology field?

Sasha: My background is in product design, and I was first introduced to 3D printing as a way to prototype my ideas at university over 10 years ago. As I honed my skills in CAD design, I started to realise just how powerful this technology could be. Instead of buying products off the shelf, I began recreating and customising them to suit my specific needs. This sparked my interest in the potential of additive manufacturing (AM) to create personalised, one-of-a-kind items that simply aren’t possible through traditional manufacturing, where uniformity and mass production often limit choice.

As I became more invested and worked with different AM processes, I understood that the more industrial nature of the Powder Bed Fusion (PBF) process has already made this concept a reality for certain applications, enabling the cost-effective production of bespoke products. It’s the most advanced form of AM, and it represents a major step towards a future where personalised manufacturing becomes more widespread. The pace at which the industry is growing is incredibly exciting, and I feel privileged to be part of it and to help make it more accessible to more people. I am also eager to see what innovations lie ahead.

Felix: As a product designer, I was first introduced to AM while working on a project with a design collective in 2013. We were tasked with producing 100 units of a lamp, but struggled to find an efficient way to manufacture the casings for the LEDs. That’s when we partnered with a company called Digits2Widgets to use additive manufacturing, specifically the selective laser sintering (SLS) PBF process, and I was immediately impressed by the technology’s capabilities. However, I could see that the potential of this technology extended far beyond what was being offered at the time.

As I researched digital manufacturing processes further, I became excited about the possibilities of mass customisation and how AM technology could streamline getting products to market. Initially, the earlier 3D printing technologies like FDM and SLA didn’t capture my interest because they lacked the ability to create high-quality, end-use parts. But once I saw the results of the SLS components in our lighting design, I realised the true potential for production, and that’s what really sparked my passion for this field.

What brought you both together and how do you complement each other?

Felix: We actually met in school, becoming friends by spending most of our time in the Design & Technology workshop and later going to study product design together. Sasha & I initially thought that we had too much crossover of skills to work together successfully. However, as the business has flourished, we have continued to develop our core skills and expertise together while both venturing into separate key roles that complement each other and bring depth and breadth to the company. In this way, my key area of expertise is software development, which has driven some key USPs for the business, which was integral to our vision.

Sasha: As Felix said, we’ve known each other since school. We shared several classes together including maths, physics and, unsurprisingly, design & technology. We would often work together on our homework and we both had a similar interest in the cross-over between art, design, and engineering. I remember us sharing videos and articles on great innovators like Eames and how they used the ‘new’ technology of plywood to bring affordable furniture to the masses. And we would talk about “The Thonet” chair, said to be the first example of flatpack. With such a long history of friendship and studying together, working together came quite naturally, and we’ve been successful at synergising our skills to grow the company together. Naturally, we took on more and more independent roles and responsibilities, but we still work closely on the development of the business.

What was the motivation behind the founding of 3D People?

Sasha: At university, Felix and I were already selling parts to our fellow students using 3D printers in our flat basement when we made the decision to get serious and start a business. We shared a vision for development of the technology and what this could look like for the product industry. While we’d always imagined designing our own products, we struggled when sourcing manufacturing and saw the opportunity in making AM more accessible to people like us. We were motivated to build a business that would enable and inspire innovative products that would only be possible through the adoption of 3D printing as a manufacturing method, and we wanted to make this more accessible.

Felix: From my own experience, finding manufacturers or fabricators and achieving successful outcomes can be so difficult. This is especially true if you are researching or using a new technology for the first time and don’t have the experience to inform the best practices. Often, in this situation, when you call a company, they won’t give you the time of day to support you to realise your project. One of the founding pillars of 3D People was to demystify the process, make it more accessible through automation, all whilst digitally and practically guiding our customers to successful outcomes.

What would you say makes you stand out from other 3D printing bureaux?

Sasha: We’ve always been committed to delivering the best for our customers — whether that’s in terms of quality output, lead times, fair pricing, or the overall customer experience. But I guess every company can and does say that. All of these things do really matter at 3D People, so instead of simply following the industry standard and adopting the same tools and equipment as everyone else, we see each challenge as a chance to innovate and improve. Our approach has evolved over time, and it’s still a constant journey to do better. As of today, I think we stand out in three key areas.

First, using automation where it really helps. We’ve streamlined many of our processes by automating anything that adds value, which has boosted efficiency in terms of both time and costs. This allows our team to focus on providing personalised care where it is needed, ensuring that our service remains premium. Second, we have introduced faster, stress-free quoting. We listened to customer feedback and developed software that enables faster, hassle-free quoting — whether instantly via our website or through an account manager in minutes. Third and finally, manufacturing excellence. While many in the industry use similar equipment and materials, we are committed to producing every part in-house. Unlike competitors who might rely on third-party suppliers, we maintain full control over our processes. We've developed systems to meticulously manage the variables involved in 3D printing, which helps us maintain consistently high standards for quality and deliver superior material finishes compared to others.

By continually striving to improve and never settling for 'good enough,' we’ve built a business that truly prioritises the customer experience and stands out in a crowded market.

Felix: Everything that Sasha said! Also, on the automation point, I would just add that we have introduced automated processes where it is efficient to do so, but we strive to keep people at the forefront of our business too. Each customer has priorities and concerns that we need to address on a case-by-case basis.

We keep our manufacturing in house and therefore also keep our expertise in house. A marketplace may have every available manufacturing method under the sun, however maintaining quality and reliability is not possible whilst utilising a large network of suppliers.

What are your priorities across the business?

Sasha: Quality and service have always been at the core of what we do. Our priority is enabling our customers to succeed, and we recognise that 3D printing, while incredibly versatile, is just one tool in the manufacturing toolbox. It’s not the all-in-one solution that some may expect, and that’s where our guidance comes in. Whether it’s through the dynamic information available via our online quoting app, offering free technical consultations, or providing design-for-additive feedback, our goal is to steer customers toward the best outcome — even if that doesn’t always lead to a sale. For us, a win is avoiding bad outcomes and helping our customers achieve better results.

Felix: Our customers are always our priority. This drives everything else we do. It is why we pushed for and achieved ISO 9001, to back up and guarantee the quality of our processes and parts. It is also why we are developing our own innovations across our service, with a particular focus on finishing techniques that go above and beyond what is currently available in the market. Another area of the business that we are pushing hard is software solutions, generating easier and quicker access to AM on a larger scale for our customers.

Since launching the company, what lessons have you learned?

Felix: Relationship building is key. When we first set up 3D People, we envisioned a modern business operating online with tools for our customers to use without interaction. The goal was speed and efficiency for our customers, so they could order the part(s) they want, when they want them, with assured quality built in. This still stands, and many of our customers do operate like this and appreciate it. However, as we grew, there was some conflict between this stated goal and our vision to demystify the AM production process. Some applications demand communication and some customers want to know who they’re dealing with particularly for repeat orders and batch production, and so we quickly learned that building great relationships with our customers, as required, allowed us to grow our business through partnerships. Flexibility and an open mind were the key here, and we operate in a way that gives our customers the service they require.

Finding ways to add value to our service has also been an area that we have learned a lot. We operate in a competitive market and our competitors are able to buy an AM machine system or technology in the same way we can. These usually come with best practices, however we have spent time on R&D and utilising multiple technologies in novel ways that has allowed us to extend our service beyond buying a piece of equipment and churning out parts. This can especially be seen with our finishing processes, which are integral to our vision of offering parts of quality indistinguishable from other polymer manufacturing processes.

Sasha: Our learning over the years has been constant. But I think one of the biggest lessons we've learned since launching the company is the importance of constantly learning and adapting. I was familiar with iterative design — testing and learning from feedback — but we quickly realised this mindset applies to unexpected challenges as well. Failures, whether from controlled tests or unforeseen issues, are opportunities to improve. Some of our biggest breakthroughs in R&D have come from mistakes, and we've formed some of our strongest customer relationships through how we handled issues when they arose.

On the operational side, we initially used third-party SaaS products to manage our production and online quoting. However, as we grew, we saw the limitations and took a leap of faith into software development. This decision gave us the flexibility to customise our systems to better fit our needs, and we've never looked back. Over time, our software has evolved into a powerful tool for managing production, improving efficiency, and monitoring quality. We've built in features to meet ISO 9001 standards, ensuring we consistently deliver the highest quality parts. This adaptability has been key to our growth and success.

What is the most intriguing application of your Additive Manufacturing service that you have fulfilled across the years?

Sasha: This is almost impossible to answer with a single application. We’ve produced parts that have journeyed to the bottom of the ocean and ventured out into space. When I stop and really think about that, it kind of blows my mind. I am also really proud that some of our parts were integral to the UK’s response during the COVID-19 crisis. Beyond that, you might even spot our parts in a box-office movie or under the hood of a supercar.

The range of applications for our technology seems endless. And while we always know exactly how our parts are made and delivered to meet strict quality standards, for me, it’s the occasional project where we don’t know what the final application actually is that really intrigues me. These mystery items spark curiosity and keep us wondering about their role in the world.

Felix: I would have to say that it was an automotive application that we fulfilled a couple of years back, in 2022. It was a fascinating project and one that highlighted to me how far AM technologies have come in terms of production applications and higher volumes. We produced 127 components per car for 80 units (over 10,000 parts in total) of a well-known marque supercar. That’s manufacturing on demand. And that customer continues to use our service today.

What comes next?

Sasha: We like to dream big while keeping our feet firmly planted on the ground. Our plans to bring the future of digital manufacturing into the present day are already well underway. In terms of the near future, however, we are investing in an expansion to our current AM capacity, we will be adding a new material to the service, and we will be releasing a big new feature to our online quote application. The details will be announced soon, so watch this space!

Felix: We’re focusing on enhancing our finishing options, including combining different finishes to offer our customers a broader range of choices. Additionally, as Sasha mentioned, we are upgrading our online platform to make it easier for customers to manage their AM projects. Our goal is to enable customers to use AM for made just-in-time production, rather than the traditional delivered just-in-time approach.

The difference is that with our platform, products can be manufactured precisely when they’re needed, rather than being produced in advance and stored until delivery. This shifts the focus from inventory management to on-demand production, reducing waste and allowing for more flexibility in manufacturing.

3D People will continue its mission to make manufacturing accessible without compromising on quality. From one-off designs through to large repeat production batches the company works with clients from a wide range of industry sectors, including, but not limited to, engineering, automotive, product design, construction, film and energy.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product