There is no clear-cut winner among the different standards and there is a lack of interoperability, even when Ethernet is used as the base network. For users and implementers of automation equipment, applying the best solution often requires supporting dissimilar network technologies.

Why Automation Gateways Matter

Jason Block | HMS Industrial Networks

Industrial IoT (IIoT)…Industry 4.0…Cloud Computing… Big Data…OEE…These are the hot-button subjects occupying decision makers at the top of every industry from factory end users to implementers, and providers, of automation equipment. Each is trying to determine how information can help them make better internal business decisions or serve as surplus value to help them better service their customers.

With IIoT in mind, the market has seen the introduction of edge gateways that allow users to collect machine and process data, perform analytics and filtering, then provide connectivity and transportation of data into information-based applications. This convergence of information and operational technology has significantly increased the value that automation brings to the factory floor, and greatly disrupted the original business models of automation equipment vendors.

Why Connectivity is Critical

What sometimes gets lost in the push to gain connectivity to the information layer is how critical connectivity is at the machine level or machine to machine. The value that information provides is only as good as the least available piece of data and with the broad implementation of industrial networks, there is a tremendous amount of diagnostic and other data available on controllers and devices.

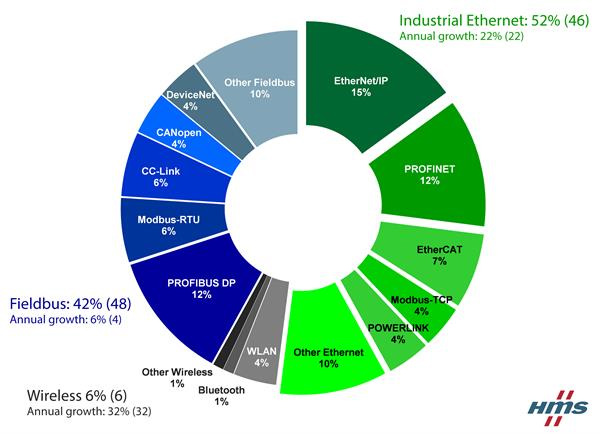

Figure 1: 2018 Industrial Network Global Market Share

The Challenges

The challenge that exists with the use of industrial networks is the amount of fragmentation between standards in the global market as shown in Figure 1. There is no clear-cut winner among the different standards and there is a lack of interoperability, even when Ethernet is used as the base network. For users and implementers of automation equipment, applying the best solution often requires supporting dissimilar network technologies.

This is a challenge that automation gateways, also known as protocol converters, have addressed very well. By navigating between multiple industrial fieldbus and Ethernet protocols, automation gateways have maximized the availability of controllers and devices, allowing for a more seamless manufacturing environment. The additional benefit, beyond interoperability of networks, is that data in network devices has been unlocked for use by machine controllers and edge gateways, providing a much more granular view of plant machinery. This allows for much better understanding of manufacturing and much better decision making.

When considering how IIoT will affect your business, always keep in mind how important machine connectivity is to this goal. Learn more on how Anybus Solutions for Industrial Automation can keep your devices connected and accessible.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product