The Role of PLCs in the Modern Industrial Revolution

New kinds of PLCs are contributing to new approaches to manufacturing and industrial systems. Many people are referring to the more general trend as a 'new industrial revolution' or 'industry 4.0.'

PLC Ladder Logic vs. Everything Else

A programmable Logic Controller is an industrial process control computer which has been "ruggedized" and adapted to control the manufacturing process. Almost all manufacturing processes are modernized and automated by adapting this technology to stay ahead of competition.

Emerson sweetens bid for Rockwell Automation to $29 billion

Greg Roumeliotis for Reuters: The new offer follows Rockwells rejections of Emersons overtures for much of this year.

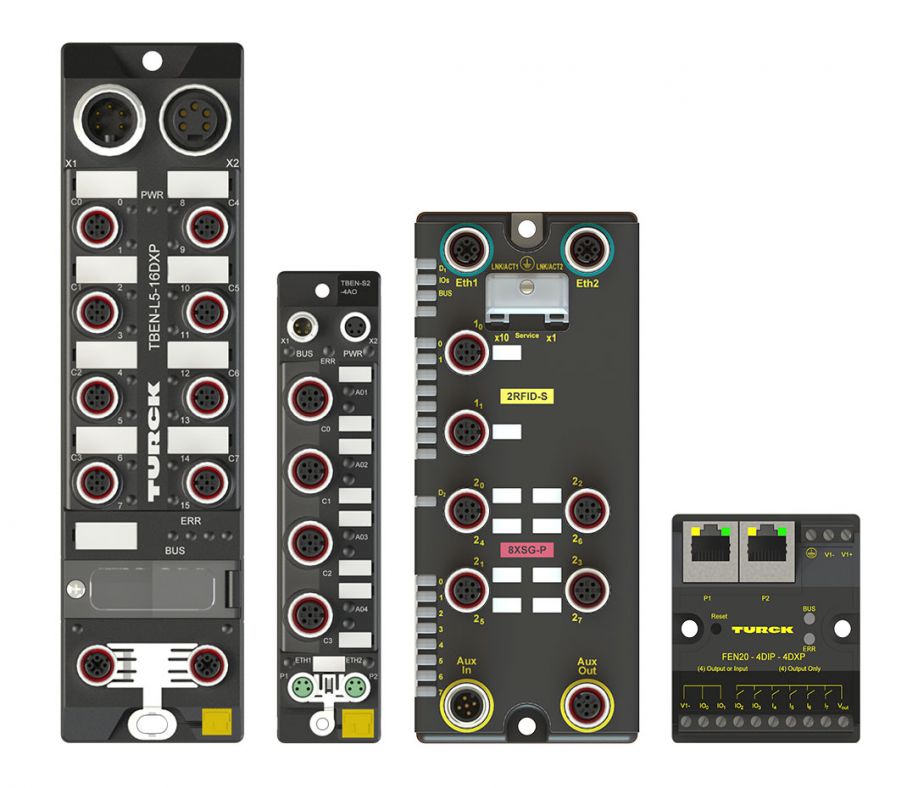

Field Logic Controllers (FLCs) expand control options for industrial environments

FLCs can be used in standalone applications or as a way to expand I/O without adding more I/O points to a PLC.

PLC vs. PAC

PLCs and PACs are similar as they both perform the same essential functions. With modern technology, their differences are becoming more blurred. The most notable difference between PLCs and PACs is their programming interface. PACs are more intricate, using C or C++. PLCs on the other hand, are programmed using ladder logic. These programming differences create distinctions in the architecture and capability between the two computers.

Records 1 to 5 of 5

Featured Product

FLIR Si1-LD - Industrial Acoustic Imaging Camera for Compressed Air Leak Detection

The FLIR Si1-LD is an easy-to-use acoustic imaging camera for locating and quantifying pressurized leaks in compressed air systems. This lightweight, one-handed camera is designed to help maintenance, manufacturing, and engineering professionals identify air leaks faster than with traditional methods. Built with a carefully constructed array of MEMS microphones for high sensitivity, the Si1-LD produces a precise acoustic image that visually displays ultrasonic information, even in loud, industrial environments. The acoustic image is overlaid in real time on a digital image, allowing you to accurately pinpoint the source of the sound, with onboard analytics which quantify the losses being incurred. The Si1-LD features a plugin that enables you to import acoustic images to FLIR Thermal Studio suite for offline editing, analysis, and advanced report creation. Field analysis and reporting can also be done using the FLIR Acoustic Camera Viewer cloud service. Transferring of images can be managed via memory stick or USB data cable. Through a regular maintenance routine, the FLIR Si1-LD can help facilities reduce their environmental impact and save money on utility bills.

Manufacturing and Automation - Featured Company

PI USA (Physik Instrumente)

PI is a privately held company that designs and manufactures world-class precision motion and automation systems including air bearings, hexapods and piezo drives at locations in North America, Europe, and Asia. The company was founded 5 decades ago and today employs more than 1700 people worldwide. PI's customers are leaders in high-tech industries and research institutes in fields such as photonics, life-sciences, semiconductors and aerospace.