PRECISION WITHOUT COMPROMISE — MICRO COMPONENT GROUP TO DEMONSTRATE PCE FOR MEDICAL DEVICES AT MD&M WEST

The Micro Component Group to Showcase Advanced Photo-Chemical Etching Solutions at MD&M West 2026

3D PEOPLE HELPS POWER BREAKTHROUGH MARITIME SUSTAINABILITY WITH ARMADA TECHNOLOGIES' PASSIVE AIR LUBRICATION SYSTEM

Armada Technologies, a Liverpool-based firm on a mission to reduce the environmental impact of global shipping, turned to 3D People to manufacture a critical part for its revolutionary Passive Air Lubrication System (PALS).

Replique Expands Global Manufacturing Partnership with Alstom

Replique now serves as a global supplier for numerous projects and subsidiaries, including locations in Singapore, Brazil, Australia, France, Italy, Germany, Thailand, and Spain.

ACCUMOLD BRINGS MICRO MOLDING PRECISION TO PHOTONICS WEST 2026 AS OPTICAL INNOVATION ACCELERATES

Visit Accumold at Booth #1848 to explore how micro molding is enabling photonics innovation through miniature plastic components that demand exceptional dimensional control and repeatability. In photonics, performance often comes down to alignment, where even small deviations can affect signal integrity, coupling efficiency, or long-term stability.

FUGO Precision 3D and Graphy Forge Strategic Partnership to Accelerate Advanced Material Integration Ahead of LMT 2026 Launch

From Idea to Print: Creality SPARKX i7 Debuts at CES 2026 for Everyday Creators

The showcase highlighted Creality's latest progress in intelligent, AI-enabled fabrication, demonstrating how advanced 3D creation technologies are becoming more accessible, intuitive, and closely aligned with everyday creative use cases.

Meshy Unveils AI Creative Lab at CES 2026, Turning AI-Generated 3D Creations into Physical Products With One Click

The leader in 3D generative AI, Meshy introduces the industry's first imagination-to-reality engine, bridging digital creativity and reality

A researcher's long quest leads to a smart composite breakthrough

Yu's team has used an advanced manufacturing technique called additive friction stir deposition to embed functional ceramic particles into metal. The result? A strong, defect-free material that can phase-shift under stress to dissipate energy and, unlike normally brittle ceramics, can be 3D-printed in bulk with full density in the as-printed state, opening up possibilities for practical applications in defense, infrastructure, aerospace, and even high-performance sporting equipment.

AMufacture to Host Industry Showcase Open Day Featuring HP Technology

AMufacture is throwing open the doors of its Portsmouth base for an Open House and Demo Day in collaboration with HP Additive Manufacturing Solutions in the new year.

Momentus Develops Additive Manufactured Fuel Tank with Strategic Partner Velo3D to be flight tested on Vigoride-7 Mission

This milestone demonstrates the potential of additive manufacturing to accelerate innovation in spacecraft design, reduce production timelines, and enable complex geometries that improve performance in demanding space environments.

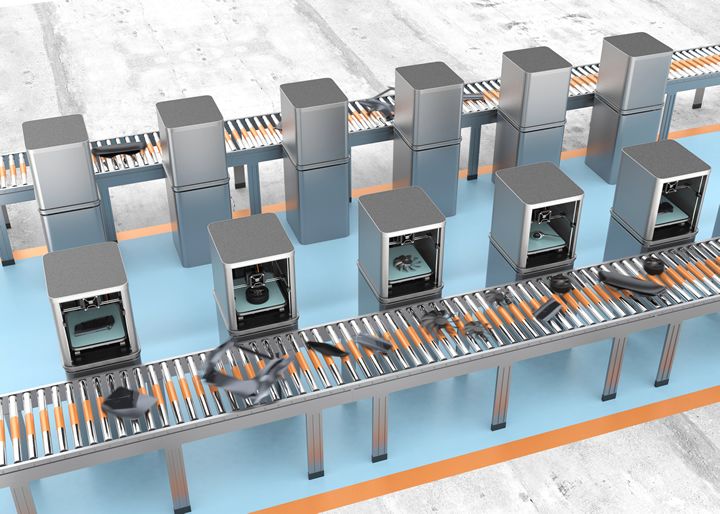

2025 Top Article - AUTOMATION IS UNLOCKING THE FUTURE OF AM SERVICES

In this article, I want to dive into the role automation plays in the approach to AM services, highlighting the benefits it delivers to customers, how it drives operational efficiency, and why it's essential for the future of this industry.

Anycubic Opens Deposits for Kobra X, Following Formnext Debut of Its Next-Generation Entry-Level Multicolor FDM Printer

Unveiled alongside the company's latest product lineup in Frankfurt, Kobra X reflects Anycubic's continued focus on simplifying advanced desktop manufacturing workflows.

2025 Top Article - How Industrial 3D Printing is Propelling Small and Mid-Sized Manufacturers Forward

With lower barriers to entry, small and mid-sized manufacturers have more opportunities than ever to integrate industrial 3D printing into their operations while avoiding the hurdles that once held them back.

Stratasys Partners with Novineer to Integrate NoviPath FDM Performance Simulation with GrabCAD Print Pro, Reducing Physical Testing Time, and Cost for Load-Bearing Parts

Engineers now able to optimize FDM parts for real applications with dramatically reduced trial-and-error testing, allowing manufacturers to design lighter, stronger FDM parts with greater confidence

Carfulan Group announces record £22.3m year as demand for advanced manufacturing solutions grows

Industry's desire for greater precision, control and additive manufacturing has helped an advanced manufacturing specialist post its best-ever year.

Records 1 to 15 of 5018

Additive & 3D Printing - Featured Product

BigRep ONE: Large-Scale 3D Printing

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 350 systems installed worldwide, it's a trusted solution for prototyping and production by designers, innovators, and manufacturers alike. Featuring a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

Manufacturing and Automation - Featured Company

Fronius Perfect Welding

We aspire to produce more than just welding systems, which is why we are the innovation leader for arc welding and are constantly developing welding processes further. In addition to welding technology for robot applications, we offer solutions for manual gas shielded arc welding, for MIG/MAG, TIG, and MMA welding processes. We also implement automated, complete welding solutions tailored to customer requirements in the field of welding automation. After all, welding creates connections - between metals, between industries, and between people. Connected by the arc, by passion, by the beat of welding.