Why You Need MindSphere in Your Facility

Contributed by Sam Hoff, CEO of Patti Engineering: When the iPhone came out on in the middle of 2007, it was an extremely disruptive technology. For the first time, we were carrying a fully-connected computer on our person. Thanks to an app store, you have a plethora of apps that can do anything from find restaurant recommendations, track your steps, find friends in the area, or tweet your views out to the world. Think about it: how your life has changed since you have started using a smartphone?

Now, if you are in operations at a manufacturing facility, how has your facility changed since 2007? Has tracking your personnel and equipment’s performance changed significantly? Maybe you have added or looked at adding a SCADA or MES system, but how readily is the data available to you? How much investment was required? Is all of your equipment on the system? What kind of improvements can you implement off of that data?

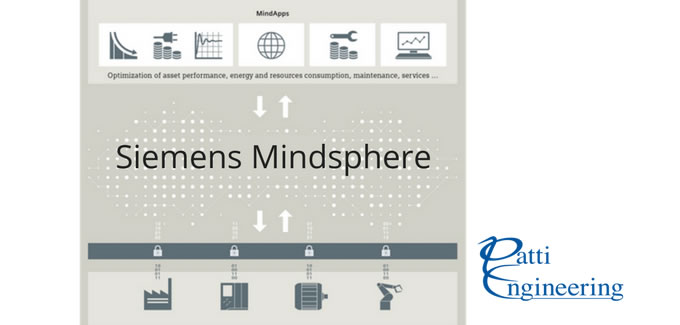

One of the reasons I am excited about the Siemens MindSphere Platform is that it has the potential to be disruptive the same way the iPhone was. MindSphere is not another off-the-shelf MES System. It is instead a platform to close the loop for IIOT (Industrial Internet of Things) by enabling devices of any manufacturer to be connected from the plant floor to the cloud.

Integrators like Patti Engineering can develop applications to monitor and present the data from the cloud. Instead of a significant up-front capital project, monitoring and presentation of the data can be paid through an operations budget. Once you hook a MindConnect Nano box to your machine, you can start collecting data.

Applications developed by integrators like Patti Engineering can crunch the data to create information that can be accessed by the operations management from anywhere (in the facility, at home, on the beach, in a meeting). More importantly, the data can be analyzed to identify areas for improvement. Large sets of data can even run through artificial intelligence algorithms. By engaging in a subscription software package, the application no longer has to be stagnant. It can be modified and fine-tuned as your processes change and mature.

In order to be competitive in Industry 4.0, we have to be smarter about our operations. If you are interested in learning what MindSphere can do for you, reach out to us. We would be happy to meet with you to discuss your ideas.

Featured Product