Industry 4.0: The Five Steps Towards A Digital Supply Chain

Stefan Schrauf, Philipp Berttram and Morten Grunwald via Forbes: If the vision of Industry 4.0 is to be realized, most enterprise processes — manufacturing, product development, customer relations, and the workplace itself — must become fully digitized. A critical element will be the arrival of the digital supply chain.

Stefan Schrauf, Philipp Berttram and Morten Grunwald via Forbes: If the vision of Industry 4.0 is to be realized, most enterprise processes — manufacturing, product development, customer relations, and the workplace itself — must become fully digitized. A critical element will be the arrival of the digital supply chain.

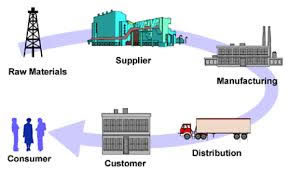

The supply chain today is a series of largely discrete, siloed steps taken through marketing, product development, manufacturing, and distribution, and finally into the hands of the customer. Digitization brings down those walls, and the chain becomes a completely integrated ecosystem that is fully transparent to all the players involved — from the suppliers of raw materials, components, and parts, to the transporters of those supplies and finished goods, and finally to the customers demanding fulfillment.

This network will depend on a number of key technologies: integrated planning and execution systems, logistics visibility, autonomous logistics, smart procurement and warehousing, spare parts management, and advanced analytics. The result will enable companies to react to disruptions in the supply chain, and even anticipate them, by fully modeling the network, creating “what-if” scenarios, and adjusting the supply chain in real time as conditions change. Full Article:

Featured Product