A 3D-printed buoy uses sensors and solar power to reveal the health of Berlin's River Spree and engage the city with its main river. To meet the project's requirements for scale, durability, and sustainability, Jakob partnered with BigRep.

3D Printed Buoy Gives Voice to Berlin's River Spree

3D Printed Buoy Gives Voice to Berlin's River Spree

Case Study from Natasha Mathew, | BigRep

Berlin’s identity has always been inseparable from the River Spree. It is the waterway on which the original centre of the city was built, a river that flows 44 kilometers through the city, shaping districts, and carrying the city’s history, art, and culture along its banks. Despite its presence and beauty, the ecological condition of the Spree remains largely unseen. The river is under mounting pressure from climate change and pollution in the canals.

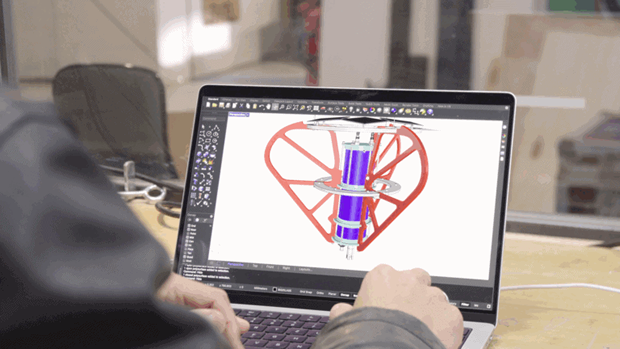

Artist, designer, and musician Jakob Kukula is working to strengthen the way Berlin listens to its river and give the Spree a more present, recognizable, and “political” voice. His goal was to create a buoy that could monitor the river’s health, share what’s going on directly with the people of the city, and inspire a renewed sense of responsibility towards the river. To meet the project’s requirements for scale, durability, and sustainability, Jakob partnered with BigRep.

The Challenge: Giving the Spree a Voice

Although the Spree is central to Berlin’s identity, its ecological condition remains largely invisible, affected by sewer overflows, architectural constraints along the riverbanks, agricultural runoff, shipping traffic, sulphate pollution from former coal mines, and heat-driven oxygen loss in the canals. These pressures accumulate quietly, seldom reaching public awareness.

Jakob wanted to create a direct and accessible relationship between the people of Berlin and the water that flows through their city. This meant building a buoy that houses sensitive electronics and is environmentally responsible enough to align with the ecological principles of the project. He needed a fabrication method that could produce sizeable parts that would fit precisely, withstand long-term exposure to water, and integrate with an internal aluminium framework.

The BigRep Solution: Large-Format 3D Printing with Recycled PETG

Thanks to the large build volume of BigRep 3D printers, the floating modules of the buoy could be printed in large sections that interlocked perfectly. BigRep’s recycled PETG was the choice of material as it had all the properties Jakob was looking for: translucent, strong, and environmentally responsible. The consistent print quality ensured that Jakob could rely on the accuracy of each component, resulting in a professional-grade prototype ready for exhibition and future deployment.

Construction of the Buoy

The buoy is constructed as a hybrid structure, produced through a combination of large-format 3D printing and CNC milling. At its core is a CNC-milled aluminum frame that gives the buoy its stability and keeps all components securely aligned. This internal skeleton sits inside the 3D-printed rPETG shell, which forms the buoyant outer body.

At the center of the structure lies the sensor module, a compact unit that houses the instruments measuring pH, dissolved oxygen, temperature, turbidity, and electrical conductivity. These sensors feed data to a small onboard computer paired with a battery pack, allowing the buoy to collect and transmit information directly from the river.

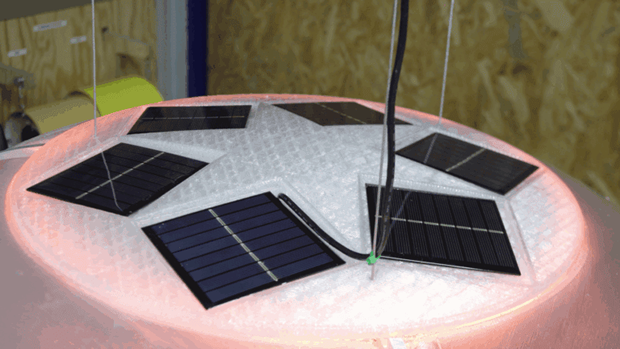

On top of the buoy sits a lid printed from rPETG, which holds a set of solar panels. These panels provide a renewable power source, giving the system enough energy to upload data to the Spree Berlin platform several times a day.

Even though the floating module appears solid, the 3D printed parts have microscopic gaps. To protect the structure from corrosion, Jakob sealed the entire printed surface with a marine-grade lacquer, creating a waterproof skin that significantly increases the buoy’s durability in the river.

Running between the printed body and the solar lid is a sealed LED strip. The LED strip turns sensor readings into a simple visual cue: green for healthy water, shifting through yellow and orange as conditions decline, and turning red when the river needs attention. It’s a quiet but powerful way of letting the Spree speak for itself.

How the Buoy Functions

Once it is floating in the river, the buoy continuously collects sensor readings and sends the information to spreeberlin.de. Anyone can check the real-time status of the river by visiting the website or by simply observing the changing colors of the buoy as they walk by.

This creates a new form of public engagement. People no longer need to interpret technical reports or wait for official advisories. The river communicates its condition directly, encouraging visitors to learn how oxygen depletion affects fish, how rainfall can temporarily contaminate the water, or why certain days are safer for swimming than others. The buoy becomes both an educational device and a living indicator of the river’s daily rhythms.

Future Plans for the Buoy

.png)

Jakob’s next phase of the project is a promising idea of larger buoys equipped with oxygen pumps. During hot summers, Berlin’s canals often experience severe drops in oxygen levels, and the city currently relies on a ship, Rudolf Kloos, to circulate through the river, pumping oxygen. A distributed network of oxygen-pumping buoys could offer a more flexible, eco-friendly alternative.

Beyond this, the plan is to introduce multiple buoys across the city, creating a continuous sensory network that tracks ecological changes over time. Additional sensor types and integration into urban planning can help Berlin build a more responsive and informed relationship with its natural systems, working at the intersection of technology, sustainability, and urban ecology.

The buoy is now on display at the Humboldt Forum in Berlin.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

BigRep

Founded in 2014, BigRep set sail to transform the 3D printing and manufacturing business. With its 1m3 volume, the BigRep ONE opens the gateway to a new dimension of 3D printing and 3D manufacturing, while the BigRep STUDIO allows fast and precise large-scale 3D printing. From furniture to vehicles to robotics, we think everything is possible. We want you to envision everything from human scale robot parts, sculptural artworks in all their full-dimensional glory, and dream the impossible world-changing designs of tomorrow while enabling you to print them today using one of our 3D printers.

Other Articles

NewsFender's 3D Printed Ballistic Fender Charts a New Course in Maritime Defense

BigRep ALTRA 280, the Ultimate High-Temperature Industrial 3D Printer

How 3D Printing is Paving the Way for Grading Contractor, C.J. Moyna & Sons

More about BigRep

Featured Product