This article explains why migration to the S7-1500 platform is becoming urgent, the hidden challenges engineers face during transition, and how modern PLC architecture supports Industry 4.0 readiness, improved reliability, and long-term performance.

Upgrading for Industry 4.0: How Siemens S7-1500 Migration Solves Hidden Legacy Challenges and Why Modern Manufacturing Can't Afford to Wait

Avadh Nagaralawala, Mining Automation & Control Engineering Consultant | PMP

The S7-300 EOL and Legacy Limitations

Siemens’ older SIMATIC S7-300 PLC has powered factories for decades, but it is now officially in phaseout. In October 2023 Siemens announced a 10-year end-of-sale roadmap (P.M400) for S7-300/ET200M, with final discontinuation (P.M410) set for October 1, 2025. This means no new S7-300 CPUs or I/O will be sold after 2025, and spare parts are only guaranteed through about 2033. Most existing lines will have S7-300 controllers approaching end?of?life, yet these legacy PLCs were designed in an era before modern cyber threats. They lack today’s built?in security and advanced diagnostics, so continuing to run them can raise risks of unscheduled downtime, security breaches, and high maintenance costs.

Waiting too long to upgrade can be costly: studies note that “unplanned downtime remains the most critical risk,” since a single failed CPU or module can halt production. In fact, Siemens and partners emphasize that proactive control system upgrades are often the most effective way to maximize a line’s longevity and equipment effectiveness (OEE). As one controls?engineering guide explains, PLC upgrades become “a necessary part of long-term production line maintenance” to keep plants running efficiently. With S7-300 parts and support winding down, many manufacturers are planning to migrate to the newer SIMATIC S7-1500 series – the modern successor designed for high performance, security, and Industry 4.0 connectivity.

Benefits of S7-1500: Speed, Diagnostics, and Security

The SIMATIC S7-1500 is a state-of-the-art controller family that builds on the S7-300’s legacy with much higher performance and features. It offers faster processing and I/O scan times, enabling tighter control loops and higher throughput. Users routinely report dramatically shorter cycle times with S7-1500 CPUs, thanks to faster multi-core processors and more on-chip memory. In practical terms, this means machines can run faster or handle more complex tasks (multi-axis motion, high-speed data logging, etc.) without slowing the production line.

Another key enhancement is integrated system diagnostics. Every S7-1500 CPU includes an onboard display and LEDs that show status and error codes. If a device fault or communication error occurs, the controller can immediately flag it on the panel or via a web interface. This built?in visibility, combined with TIA Portal engineering tools, lets technicians diagnose issues much more quickly. For example, the controller can trace and log recent process values or system events, helping engineers pinpoint intermittent faults. One industry source notes that the S7-1500 “delivers faster cycle times, integrated diagnostics and enhanced cybersecurity features” compared to older PLCs.

Security is built into the S7-1500 from the ground up. It supports secure boot, signed firmware, and user?role protection so that only authorized personnel can change the program. Data encryption and logging (Syslog support) make it much harder for an attacker or malware to tamper with the controller undetected. In contrast, legacy S7-300 hardware “was designed in an era with fewer digital threats and does not include advanced protections,” making it vulnerable by today’s standards. Using an S7-1500 can therefore help meet modern cybersecurity standards and prevent incidents that could stop production or corrupt IP.

The S7-1500 also integrates tightly with safety and motion control. Optional “F” (fail-safe) CPUs in the 1500 family are certified to SIL3/PL e for functional safety. That means the same PLC chassis can handle both normal logic and safety interlocks (e.g. emergency stops, guard monitoring) without separate safety relays or controllers. In high-speed lines, dedicated motion CPUs and technology modules (for camming, robotics kinematics, etc.) give truly high-performance motion control natively in the controller. All these advanced features – high speed, system diagnostics, integrated safety, and robust security – come standard in the S7-1500 platform and were simply not available on the older S7-300.

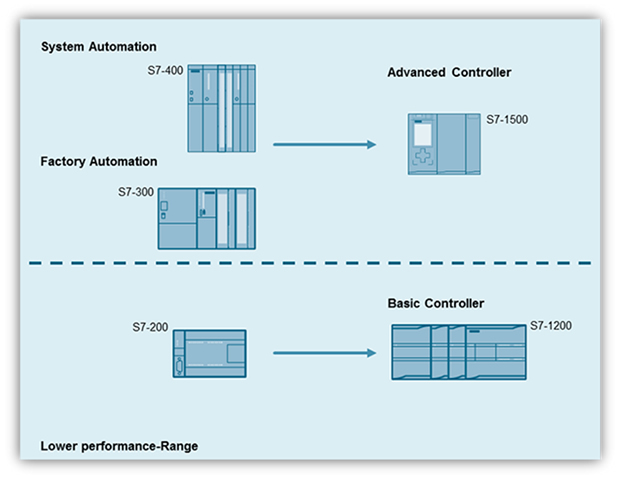

Fig-1 Siemens Controllers

Debunking Migration Myths and Challenges

Many plant managers worry that upgrading the control system means months of downtime or rewriting all the code. Siemens has provided tools and support to ease the transition from S7-300 to S7-1500. In most cases the existing PLC program can be imported into the TIA Portal and converted with minimal edits. Siemens offers compatibility charts and conversion guides, and TIA Portal can automatically map many data types and instructions. A recent industry news article notes that Siemens “supports migration with compatibility charts, software wizards and training programs” to streamline the process.

Another common concern is cost. While new hardware and software licenses require capital, this must be weighed against the cost of unplanned failures on old systems. As one source emphasizes, legacy controllers “are expected to fail and require replacement long before the line’s mechanical equipment”. In fact, planning a timely upgrade is often far cheaper than emergency repairs when a factory is already in production. Upgrading is also an investment in productivity: controlling equipment with S7-1500 typically increases overall equipment effectiveness (OEE) by reducing cycle times and minimizing downtime. The same analysis points out that control upgrades are “the most effective way to maximize a line’s longevity and OEE metrics” while keeping long-term costs down.

Some engineers worry that personnel will need retraining. But because TIA Portal is the unified Siemens platform, the skills learned on one machine readily apply to others. TIA Portal is more intuitive than the older Step 7 environment, with graphical diagnostics and one-click cross-references. Training materials and Siemens support make onboarding straightforward. In short, the “myth vs. reality” is that modern PLCs demand long retraining times — whereas in practice, the improved usability of the S7-1500/TIA environment accelerates troubleshooting and commissioning.

Other technical issues – like migrating I/O modules – are also manageable. The S7-1500 uses the SIMATIC ET 200MP (or SP) I/O modules as the recommended replacements for the old ET 200M system. However, in many cases existing field I/O (sensors, actuators) and network cabling remain unchanged. Only the controller and any proprietary I/O racks need swapping. Engineers can stage upgrades one machine or cell at a time, converting and testing in a sandbox before putting it online. For example, the new controller can be bench?tested with the existing program via a PLC simulator, then swapped into the line during a scheduled maintenance window. With careful planning and Siemens documented migration paths, most factories have shown that an S7-1500 upgrade can be accomplished with minimal disruption to production.

Hidden Challenges Engineers Face During S7-300 to S7-1500 Migration

While the benefits of S7-1500 are clear, engineers often discover that migrating from S7-300 is not a one-click process. Modern PLCs operate differently, and these differences—if not planned for—can slow down commissioning or cause unexpected system behavior. Below are the most common migration challenges based on real engineering experience.

1. Legacy Code That Doesn’t Convert Cleanly

Many S7-300 systems evolved over years or decades. Engineers often face:

* Obsolete instructions that have no S7-1500 equivalent

Old PID blocks, legacy timers, custom FBs, or instructions like SFC 46/47/51 may convert into “unsupported” blocks requiring manual rewrites.

* Heavy reliance on M-memory (markers)

Older programs were built on absolute addressing (M0.0, M10.4…), making the logic brittle.

S7-1500 enforces symbolic programming, so engineers must reorganize memory into clear tag structures or UDTs.

* Nested, complex networks

Large ladder networks or deeply layered FC/FB chains often fail to convert cleanly due to new execution and scan-time rules.

Result: The engineer must refactor sections manually, translating old logic into structured, readable blocks.

2. Differences in Fault Handling and System OBs

One of the biggest surprises engineers encountered:

S7-1500 does NOT support granular OB82 diagnostics

S7-300 provided multiple subcodes in OB82/OB86 for module faults.

S7-1500 abstracts these into system diagnostics instead.

This means:

• Fault reactions must be redesigned

• Machine interlocks tied to OB82 subcodes need re-engineering

• Custom fault logic is sometimes completely rewritten

Engineers must map old OB-family behavior into the new diagnostic framework or risk losing protection logic that existed in the old system.

3. I/O Module Differences and Hardware Re-Addressing

Even though ET200MP is designed as the S7-300 successor, several engineering issues arise:

• Channel numbering changes

• Module parameterization is stricter

• Default behaviors differ (e.g., substitute values, safe states)

• Interrupts and hardware alarms are handled differently

If the engineer blindly imports the old hardware config, the system may behave unexpectedly—even though the logic seems identical.

4. PROFIBUS vs. PROFINET Realities

Many S7-300 plants still run on PROFIBUS.

When migrating, engineers face:

• PROFINET naming requirements

• IP addressing strategy

• Network topology decisions (star vs. ring)

• Device replacement if old PROFIBUS modules have no PROFINET equivalents

The engineer must also rewrite hardware addresses, device names, and all corresponding PLC tags.

5. Timing Differences and Scan Cycle Behavior

S7-1500 is much faster—sometimes too fast for legacy systems.

This creates real issues:

• Mechanical actuators may not handle higher switching frequencies

• Old debouncing logic becomes too fast

• Analog filtering behaves differently

• Motion timing sequences need returning

In some migrations, engineers intentionally introduce artificial delays to keep machine behavior stable.

6. Safety Logic Conversion (S7-300F → S7-1500F)

Fail-safe logic brings its own challenges:

• Safety libraries change

• Some F-blocks are discontinued

• Wiring diagrams require revalidation

• Safety signatures must be regenerated

• Safe outputs cannot behave the same way as legacy wiring

This requires close coordination with safety engineers and validation teams.

7. Data Block Structures and UDT Normalization

One of the most time-consuming tasks is reorganizing legacy Dbs.

Typical issues include:

• Packed structures that break alignment rules in S7-1500

• Mixed data types squeezed into a single DB

• Old HMI addresses tied to absolute memory bytes

• Multiple machines sharing the same data layout inconsistently

Engineers must build clean UDTs, remap DBs, and update HMI tags—sometimes hundreds or thousands of them.

8. HMI & SCADA Tag Breakages

When migrating:

• Old WinCC/WinCC Flexible tags break

• Absolute addresses no longer exist

• Alarm messages tied to OB codes no longer match

• Faceplates referencing old blocks must be rebuilt

This is especially challenging when plants run 300–500 HMI screens.

9. Industry 4.0 Requirements Add Pressure

The move to S7-1500 is often the first step towards:

• OPC UA connectivity

• MES/ERP integration

• Cloud or historian analytics

• Predictive maintenance models

However, if the PLC tags and structures are not modernized properly during migration, all future digital initiatives become difficult.

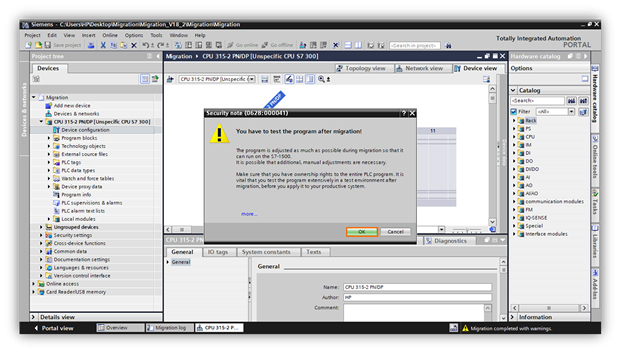

Fig-2 Challenges with Migration

Real-World Impact: Production, Reliability, and Safety

In practice, plants that switch from S7-300 to S7-1500 see measurable benefits. Production lines run smoother and faster thanks to shorter PLC scan times and more responsive control loops. For instance, one food-industry integrator reports that a bottling line’s cycle dropped by over 20% after moving to S7-1500 CPUs with advanced motion modules. Even simple processes gain efficiency: faster analog scans and data processing mean tighter temperature and pressure control in processes like curing or sterilization.

Maintenance crews also benefit from higher reliability and visibility. The S7-1500’s automatic diagnostics catch failing modules early – for example, a warming power supply or intermittent I/O card will trigger an alarm before it causes a line?stopping fault. Many factories set up email or SMS alerts from the PLC, so technicians can address issues during normal hours rather than chasing breakdowns. The ability to record long-term trace data (a built-in feature) also helps with quality control. For instance, a pharma plant might log every batch’s sensor reading in the controller; if a recall issue arises, the logged data provides a digital paper trail.

Safety improvements are another real gain. By using S7-1500F fail-safe CPUs, machines can have safety interlocks and emergency stops implemented in software rather than bulky relay circuits. This reduces wiring errors and hardware costs. For example, when a guard door opens, the S7-1500F CPU instantly halts motion based on certified safety logic (up to SIL3) – all while the standard CPU continues running the rest of the process. Integrated safety means faster safe reaction (no separate safety PLC lag) and clearer diagnostics: an error message will identify which safety function was triggered. Such tight integration of standard and safety logic is unique to modern controllers and contributes directly to workplace safety and uptime.

Overall, automation upgrades translate to improved OEE and a lower risk profile. Siemens notes that many plants have spare-part guarantees for legacy gear running out, making any failure a major emergency. Migrating to S7-1500 before critical deadlines ensures continuity. In the process, plants often see uptime increase: one survey found that companies replacing old PLCs with new ones reported up to 30% less downtime after the switch. Although each facility is different, the trend is clear: modern PLC hardware enhances production speed, system reliability, and process safety, giving a quick return on the upgrade investment.

Conclusion

Upgrading from Siemens S7-300 to S7-1500 is more than a routine hardware swap – it is a strategic move toward smart manufacturing. The legacy S7-300 controllers have served well but are now officially obsolete, with no new units or updates after 2025. In contrast, the S7-1500 brings dramatically improved performance (much faster scan times), built-in diagnostics, and robust cybersecurity protections that align with today’s requirements. This migration also positions factories for Industry 4.0: the S7-1500 natively supports the digital connectivity and data exchange that modern production systems demand.

Avadh Nagaralawala is a control system Consultant with more than 12 years of experience in manufacturing automation, PLC upgrades, control architecture redesign, and modernization of legacy industrial systems. He has spent more than a decade working on Siemens S7-300 to S7-1500 migrations, SCADA integrations, and Industry 4.0-driven controls engineering projects. His writing focuses on practical engineering insights, reliability improvement, and the digital evolution of factory operations.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product