New 200 mm capacity is often built from scratch or heavily refurbished, making it easier to apply the same automation patterns used in 300 mm fabs. The result is convergence; wafer diameter still affects output per lot, but it no longer indicates the level of automation.

Why Automation, Not Wafer Size, Determines Semiconductor Fab Cycle Time

Dr. Fahad Golra, Director Product Innovation | Agileo Automation

The long-held belief that 300 mm wafer fabs are inherently more productive than 200 mm fabs is no longer true. While wafer size does affect the number of chips per wafer, cycle time and predictability are mainly determined by the generation of the manufacturing execution system (MES), the degree of tool-host standardization, and the level of automation in material handling. New 200 mm fabs, along with well-executed retrofits, increasingly use the same GEM300 standards, automated material handling systems (AMHS), and equipment front-end module (EFEM) robotics that define 300 mm automation. The priority for original equipment manufacturers (OEMs) and fabs is to modernize interfaces and carrier delivery and then tune dispatching and data flows. If done correctly, a 200 mm fab can compete on cycle time with many 300 mm lines that have similar process complexity.

From 200 mm to 300 mm

The semiconductor industry's shift to 300 mm wafers in the early 2000s was driven by cost. A 300 mm wafer has approximately 2.25 times the surface area of a 200 mm wafer, allowing for more die production per run if the process and equipment are similar. To smoothly handle heavy carriers at scale, 300 mm fabs adopted automated material handling early on. Overhead hoist transport, FOUP logistics, standardized load ports, and fully integrated tool-host coordination became standard. In contrast, many older 200 mm plants relied on carts, open cassettes, and a basic SECS/GEM interface. This design choice created the original automation gap.

The semiconductor industry's shift to 300 mm wafers in the early 2000s was driven by cost. A 300 mm wafer has approximately 2.25 times the surface area of a 200 mm wafer, allowing for more die production per run if the process and equipment are similar. To smoothly handle heavy carriers at scale, 300 mm fabs adopted automated material handling early on. Overhead hoist transport, FOUP logistics, standardized load ports, and fully integrated tool-host coordination became standard. In contrast, many older 200 mm plants relied on carts, open cassettes, and a basic SECS/GEM interface. This design choice created the original automation gap.

Two things changed. First, the GEM300 standard suite evolved into a reliable framework for coordination throughout the factory. Second, increasing demand for analog, power, MEMS, and wide-bandgap devices led to increased investment in 200 mm. New 200 mm capacity is often built from scratch or heavily refurbished, making it easier to apply the same automation patterns used in 300 mm fabs. The result is convergence; wafer diameter still affects output per lot, but it no longer indicates the level of automation.

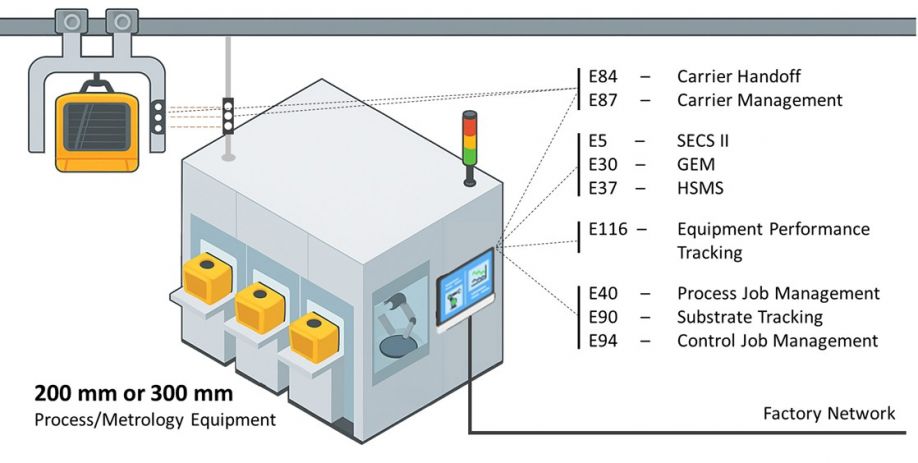

GEM300 capabilities that matter in any wafer size

GEM300 suite extends SECS/GEM with a set of standards that enable end-to-end automation. The following capabilities are key elements that equipment suppliers (OEMs) should incorporate and that integrated device manufacturers (IDMs) should demand.

Automated carrier hand-off and carrier management (SEMI E84 & E87)

While not part of the GEM300 suite, E84 defines the parallel I/O handshake used between automated material-handling systems and equipment load ports. This handshake ensures that carriers are loaded and

unloaded reliably and safely. E87 specifies the behavior of host equipment for automated and manual carrier transfers, including buffer behavior and error handling. Together, they create a verifiable, hands-free FOUP or cassette delivery routine. In practice, this may involve retrofitting 200 mm tools with sensors, interlocks, and E84 I/O, and then enable E87 logic in the tool controller and host.

Process and control job management (SEMI E40 & E94)

E40 formalizes process jobs, so the host can specify what materials to use, the sequence of steps, and the recipes to apply. E94 provides control jobs to group multiple process jobs as one directed unit of work and lets the host direct their execution sequence, manage priorities, and control each job’s lifecycle (start, pause, stop). These two standards replace manual starts and local spreadsheets with clear job orchestration. Dispatching can prepare the next job before the current run ends. This cuts idle time and supports just-in-time carrier delivery.

Wafer and module level tracking (SEMI E90 & E157)

E90 specifies how equipment reports the state and location of each wafer as it moves through the tool. This process allows for lot splitting, selective routing, rework control, and complete wafer genealogy. E157 adds to this by detailing step-level execution at each processing location. This ensures the host knows which module performed each task, when, and how long it took. When used together, E90 and E157 provide the MES with a synchronized view of material and step history. In 200 mm upgrades, this combination often serves as the initial data foundation for better dispatching, tighter cycle-time control, and faster yield learning.

Equipment performance and state tracking (SEMI E116)

E116 describes how to track equipment performance, so hosts can consistently collect data on uptime, blocked time, idle time, and throughput without operator input. Fabs use this data to calculate OEE and RAM metrics under their E10 policy. This yields consistent visibility and dependable dispatch signals across tools.

Standard EFEM with robots at the tool interface

Both 200 mm and 300 mm cutting-edge tools come with EFEMs that include load ports, aligners, atmospheric or vacuum robots, and mini-environments. Robots, rather than people, handle wafers at the tool boundary. This reduces defects, stabilizes takt, and allows the AMHS to closely align with the tool schedule. For OEMs, providing the same EFEM platform with options for 200 mm open cassettes, 200 mm SMIF, or 300 mm FOUP makes integration easier across fab generations.

These capabilities give the MES a real-time, reliable view of materials, tools, and transport, along with the ability to act on that information. This is what bridges the gap between a well-run 200 mm fab and a 300 mm fab.

Closing the gap in modern 200 mm fabs

New 200 mm lines increasingly use OHT or AMR fleets from day one. When ceiling height or layout restricts OHT, floor-based AMRs or conveyors can eliminate manual moves and work with E84/E87 at the load ports. Retrofitted fabs usually start with a pilot. This involves adding E84 hardware and E87 logic to a high-runner area, setting up basic carrier routing, deploying E40/E94 job control on selected tools, and enabling E90 tracking. To reduce risk in this pilot, teams often test E84/E87 timing and fault handling offline using a bench set-up, such as E84 PIO Box with Speech Scenario, which simulates either the tool or the transport. Once data fidelity and move reliability are proven, the scope expands bay by bay. The common surprise is that the biggest wins come not from raw transport speed, but from latency reduction. Lots stop waiting for humans to notice them. Tools stop idling for lack of the next job. Dispatching aligns OHT move timing with carrier availability, aided by E87 Carrier Complete Prediction (CCP, formerly Carrier Ready to Unload Prediction), and buffers shrink because arrival time variability falls.

Recommendations for IDMs and OEMs

For IDMs

- Upgrade by capability, not by bay. Start where you see queueing issues and where you have

the tools to change behavior. Pilot E84/E87 retrofits and E40/E94 job control in a focused area. Include E90 tracking within the same scope, so that you can measure the impact at the wafer level.

the tools to change behavior. Pilot E84/E87 retrofits and E40/E94 job control in a focused area. Include E90 tracking within the same scope, so that you can measure the impact at the wafer level. - Modernize the MES and dispatch rules. Make sure your host can consume GEM300 events in real time and run rules that consider carrier positions, recipe families, set-up times, time constraints, and hot lots. If the MES cannot do this, add a scheduling layer to bridge the gap until you replace the MES.

- Treat AMHS as a tool. Set key performance indicators (KPIs), preventive maintenance, and redundancy plans. Monitor OHT queues and AMR turn times. Design for graceful degradation, so that a local fault does not stall the entire plant.

- Provide instruments for decisions. Data from E116 and E157 should feed dashboards that operations and engineering teams actually use. Focus on metrics that affect cycle time, such as blocked and idle states, mean and variance of move times, and module-level step durations.

- Secure your stack. As you add interfaces and data paths, follow industry security guidelines and segment control networks. Automation without security increases operational risk.

For OEMs

- Ship GEM300 by default. Provide E40, E87, E90, and E94 alongside E84, E116, and E157 as standard options, validated together. Make control jobs and process jobs first-class features in your controller.

- Offer a retrofit path. Many fabs will ask you to upgrade their existing tools. Documented retrofit kits for E84 I/O, load-port options, and controller upgrades help with integration and speed up qualification.

- Abstract integration. Use a modular connectivity stack, so customers can adopt SECS/GEM, GEM300, and EDA progressively. Frameworks like A²ECF Semi follow this approach and reduce compliance time for new tool variants with SEMI standards.

- Design EFEMs for both worlds. Support 200 mm open cassettes, 200 mm SMIF, and 300 mm FOUP with common mechanics wherever possible. A single EFEM family that covers both sizes is a significant advantage.

- Expose useful diagnostics. Make E116 and E157 data easy to access. Provide module-level events and simple health signals, so hosts can dispatch intelligently and maintain uptime.

Cycle time leadership is no longer dependent on wafer diameter. It comes from standardized carrier delivery, deterministic job control, wafer-level visibility, and actionable performance data. All of these apply to both 200 mm and 300 mm production lines. The fastest way for wafer fabs to improve is to bring their tools to GEM300 parity, treat the AMHS as an essential tool, and use a modern scheduler that tracks real events. For OEMs, a successful approach is to provide turnkey, retrofittable, and secure GEM300 capabilities, while offering customers clear choices for EFEMs and connectivity that work with different wafer sizes. If these actions are executed well, they will shorten cycle time, stabilize variability, and enhance delivery without changing wafer diameter.

Dr. Fahad Golra is Director of Product Innovation at Agileo Automation, a French firm specializing in equipment connectivity, control, and supervision solutions for the global semiconductor manufacturing industry. Since joining in 2019, he has driven practical innovations in connectivity technologies, data modeling, and communication architectures. Actively involved in SEMI and the OPC Foundation, Dr. Golra advocates Industry 4.0 adoption, focusing on interoperability, digital twins, and edge-to-cloud architectures. Over his 15-year career, he has served in academia, research, and industry. He is a recognized speaker at global semiconductor events and an accomplished author of conference papers and articles, contributing extensively to the field’s ongoing evolution.

Dr. Fahad Golra is Director of Product Innovation at Agileo Automation, a French firm specializing in equipment connectivity, control, and supervision solutions for the global semiconductor manufacturing industry. Since joining in 2019, he has driven practical innovations in connectivity technologies, data modeling, and communication architectures. Actively involved in SEMI and the OPC Foundation, Dr. Golra advocates Industry 4.0 adoption, focusing on interoperability, digital twins, and edge-to-cloud architectures. Over his 15-year career, he has served in academia, research, and industry. He is a recognized speaker at global semiconductor events and an accomplished author of conference papers and articles, contributing extensively to the field’s ongoing evolution.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product