Max AI doesn’t just bridge the execution gap - it sets a new standard for modern manufacturing. By acting in real time - watching, thinking, and doing - it removes the friction and firefighting that once consumed operators, supervisors, and planners.

Using AI to Solve the “Execution Gap” in Manufacturing

Q&A with Henry Foster, Director of Marketing | MachineMetrics

Please tell us about yourself and MachineMetrics.

I'm Henry Foster, Director of Marketing at MachineMetrics. My career has focused on the intersection of manufacturing and technology, starting with enterprise-scale IoT initiatives at PTC, where I marketed both Kepware’s industrial connectivity solutions and the ThingWorx IIoT platform. I then shifted focus to the mid-market, joining MachineMetrics to help drive adoption of our market leading MES for discrete manufacturing.

MachineMetrics is the industry’s leading production intelligence platform. We help manufacturers boost throughput, reduce downtime, and drive continuous improvement with next-generation MES and AI-powered machine monitoring software.

Our mission is to close the execution gap between ERP systems and shop floor execution. By transforming real-time machine data into actionable insights we enable discrete manufacturers to improve OEE, hit delivery targets, and empower teams to execute with greater speed, clarity, and confidence than ever before.

How is artificial intelligence reshaping the modern factory?

AI is pushing manufacturing into a new era - it's enabling what we call the intelligent factory. Instead of relying on paper, manual reporting, or even digital dashboards, AI empowers systems to think and act in the moment - augmenting people and automating tasks.

With MachineMetrics, we don't think of AI as futuristic tech. It’s about practical, daily wins and supporting key jobs-to-be-done: catching tool failures before they cause scrap, identifying when a setup is falling behind, or recommending schedule changes when machines go down. And with Max AI, we’re taking this further - delivering digital employees that not only detect problems but recommend solutions and automate tasks.

AI makes the knowledge of your 30-year veteran instantly accessible to every operator. It surfaces critical insights that were once trapped across multiple systems. And it takes away many of the time intensive tasks that are required on a daily basis, whether it be generating reporting, communicating across the shop floor, or updating key production systems. As adoption grows, it raises the bar for everyone - driving a new level of competitiveness across the industry. The reality is that AI, especially in the discrete manufacturing space, is very much still in its infancy - but we are seeing it move faster than any other technology initiative.

What is the “execution gap” you’ve observed in manufacturing, and why is solving it so critical today?

The execution gap is the disconnect between ERP plans and shop floor reality.

Your ERP might say Job A should finish at 2 PM - but in reality, a machine breaks, a setup runs long, or an operator runs out of material. The ERP can’t anticipate these hiccups, and it certainly can't see them and adjust in real time. That gap - between plan and reality - is where efficiency is lost, quality issues emerge, and delivery commitments are missed.

Solving it is critical because today’s manufacturers can no longer rely on manual interventions or reactive decision-making. As labor shortages grow and operations become more complex, the only scalable way to improve productivity is by closing this gap. Fixing the delayed feedback loop between the shop floor and business systems is essential to enabling the kind of real-time decisions and intelligent automations that define the next generation of operational efficiency.

What are some of the roadblocks to effectively utilizing AI in manufacturing?

There are a few big ones:

- Data Silos: Most manufacturers don’t have accurate, real-time production data. Part of the data is trapped in machines, operational info and business context lives in ERP, and critical documents and instructions may live in a shared drive - or in the minds of experts on your team.

- Complexity: Most solutions demand significant technical expertise and engineering resources. With this DIY approach, teams are left to figure out how to capture the right data, structure it properly, and build applications that not only work but also scale beyond a small pilot into full production environments.

- Lack of Context: Even if you have “good” data, it often lacks the operational context needed for AI to act intelligently. While ChatGPT is inexpensive, it has no context on your work orders and jobs, no real-time production data, no instruction on how to do a setup on your machines, etc. Without your business context, the AI serves little value.

Without a strong data set, context specific to your operation, and tools to actually drive AI applications, it will be incredibly difficult for manufacturers to take advantage.

Why is MachineMetrics uniquely positioned to deliver AI solutions for manufacturers?

For over a decade, MachineMetrics has led the industry in machine connectivity - capturing real-time data from virtually any piece of discrete manufacturing equipment, whether it's a brand-new CNC, a decades-old press, or even a manual process like deburring or assembly.

But connectivity is only the beginning. MachineMetrics offers out-of-the-box ERP connectors that synchronize real-time machine data with critical business context - such as work orders, operations, parts, labor tracking, and scheduling.

The platform also ingests tribal knowledge and critical documentation - SOPs, setup guides, troubleshooting playbooks - through our Knowledge Hub. This transforms static content into dynamic, AI-ready context.

And all of this sits atop a flexible, cloud-native architecture built for rapid deployment and extensibility. Out-of-the-box solutions for the Core Four - OEE, downtime tracking, scheduling, and work order management - come standard with intuitive no-code custom reporting and configurable workflows.

Tell us about Max AI.

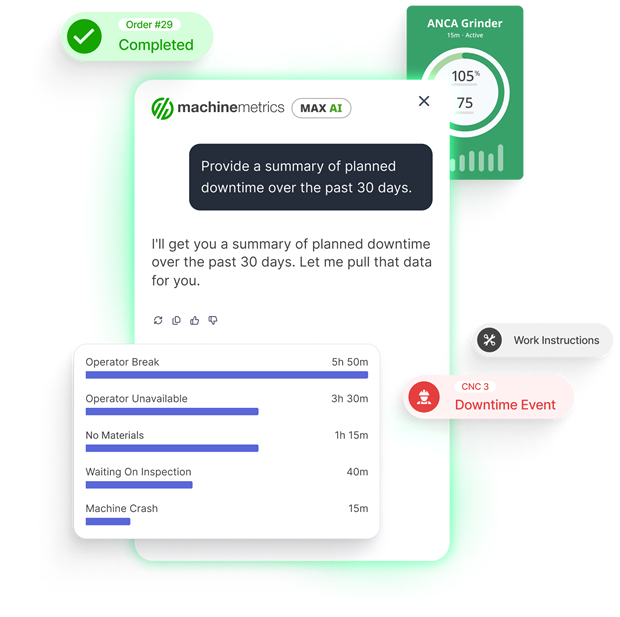

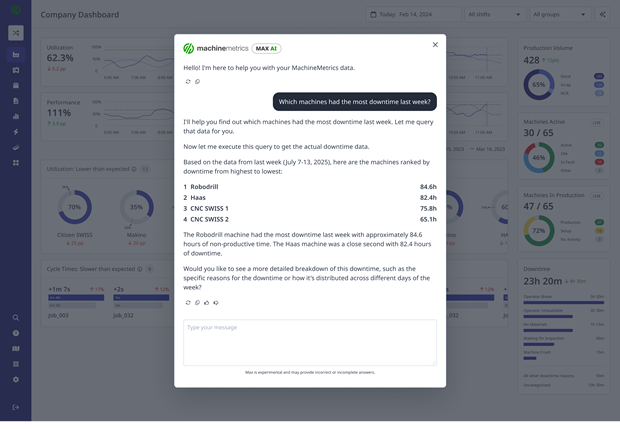

Max AI is the intelligence layer of MachineMetrics, extending into every aspect of our MES platform. Built to automate tasks and augment your people, Max AI tackles the daily challenge of production execution, from assisting operators with machine setups to analyzing plant performance and developing a prioritized action plan.

You can think of Max AI as the shop floor’s AI workforce - or digital employees - each trained in a different aspect of manufacturing execution. Max AI watches what’s happening, understands what it means, and takes action in real time - either in the form of providing key insights, offering recommendations, or automating tasks for you.

There are three key features of Max AI that will be available upon launch (which you can join live if you would like) with others planned for late 2025 and 2026.

- AI Agents: Role-based digital coworkers that guide operators, supervisors, and planners in real time - surfacing problems, recommending next steps, and keeping work on track without dashboards or delay.

- Knowledge Hub: A centralized source of SOPs, manuals, and tribal know-how that agents draw on to deliver contextual guidance when and where it’s needed most.

- Data-Driven Chat: A conversational interface that lets anyone - from CXOs to operators - ask questions in plain language and get real-time, source-backed answers from live production data.

What core manufacturing challenges does Max AI aim to solve?

Max AI closes the loop between ERP planning and shop floor execution - empowering your team with the intelligence, context, and speed to lead every shift with confidence.

With MachineMetrics Max AI, we are targeting critical and costly production issues and opportunities that present themselves daily:

- Late jobs and shifting priorities

Example: An ERP schedule says a high-priority job should complete at 2 PM, but Max AI automatically detects a machine breakdown at 10 AM and reprioritizes the schedule in real time to keep commitments on track. - Setup mistakes and tribal knowledge loss

Example: A new operator is unsure how to perform a complex setup. Max AI instantly serves up step-by-step guidance based on documentation in the Knowledge Hub. - Ineffective continuous improvement loops

Example: Instead of waiting for monthly Kaizen reviews, Max AI flags a cycle time deviation mid-shift, recommends corrective actions, and records the results for continuous improvement analysis. - Reporting bottlenecks and misaligned data

Example: Rather than managers spending an hour compiling shift reports, Max AI auto-generates real-time performance summaries and emails it to the team on a regular frequency. - Unplanned downtime and poor maintenance coordination

Example: When a certain downtime reason is detected by Max AI, a work order is automatically generated in the CMMS.

Max AI doesn’t just bridge the execution gap - it sets a new standard for modern manufacturing. By acting in real time - watching, thinking, and doing - it removes the friction and firefighting that once consumed operators, supervisors, and planners, freeing them to focus instead on high value tasks and continuous improvement.

Henry Foster is the Director of Marketing at MachineMetrics. Henry has spent the past eight years of his career in the Industrial IoT space, promoting the adoption of scalable production monitoring and analytics for the discrete manufacturing industry.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product