Lean manufacturing remains the timeless backbone of operational excellence. It provides the structure, culture, and discipline that no technology can replace. But in an era of vast data and real-time demands, AI acts as a powerful multiplier.

AI + Lean: How U.S. Manufacturers Can Blend Tradition with Technology

Article from | Orca Lean

Lean manufacturing has guided American factories for decades, proving itself as one of the most effective systems for building efficiency, reducing waste, and empowering workers. But in today’s environment, manufacturers face new pressures: global supply chain volatility, increasing product complexity, and an explosion of data from connected machines.

Artificial Intelligence (AI) is often framed as a disruptive replacement for traditional methods. In reality, AI and Lean are not competitors — they are complementary. By blending AI’s data-driven intelligence with Lean’s proven discipline, U.S. manufacturers can achieve speed, precision, and resilience without abandoning the principles that made them strong.

Why Lean Principles Remain the Foundation?

Lean is more than a toolbox; it is a philosophy rooted in respect for people and the relentless pursuit of waste elimination. Tools like PDCA (Plan-Do-Check-Act), Kaizen, and Standard Work have guided organizations through decades of transformation. They remain powerful because they are not dependent on technology — they are based on human-centered discipline, structured problem-solving, and a focus on value.

Even as factories adopt robotics, IoT sensors, and digital dashboards, Lean provides the cultural backbone. Without it, technology becomes fragmented, disconnected from daily work, and ultimately ineffective. Every successful implementation of new tools — including AI — rests on Lean principles such as:

- Clarity of purpose: Define what problem is being solved.

- Standardization: Ensure consistency across shifts, sites, and teams.

- Visual management: Make performance visible and actionable.

- Empowerment: Equip operators to identify and solve problems at the source.

In short, Lean is timeless. Any emerging technology must support, not replace, this foundation.

The Opportunity: Extending Lean with AI

The modern factory is a data-rich environment. Machines stream information about cycle times, temperatures, vibrations, and energy usage. Quality systems capture defect data. Supply chain platforms generate forecasts and alerts. While Lean methods teach us how to focus on what matters, manually processing these vast data sets is beyond human capacity.

This is where AI becomes valuable. Rather than disrupting Lean, AI strengthens it by:

- Accelerating root cause detection — analyzing patterns across thousands of variables.

- Revealing hidden inefficiencies — spotting micro-trends invisible to manual observation.

- Shortening feedback loops — turning real-time data into actionable insights.

- Scaling insights across sites — ensuring lessons from one plant are applied everywhere.

Think of AI as a microscope for Lean. It doesn’t change the rules — it helps teams see more clearly, respond more quickly, and sustain improvements over time.

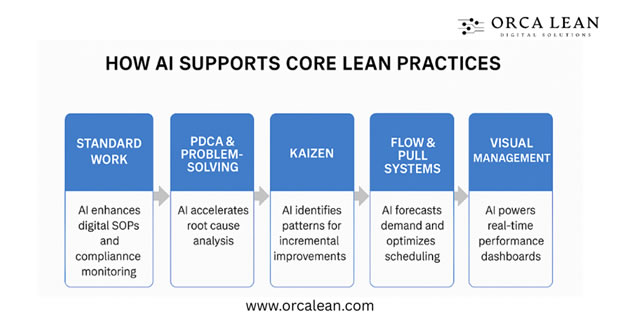

How AI Supports Core Lean Practices?

The power of AI lies in its ability to work hand-in-hand with Lean’s most important practices.

1. Standard Work

Standard work ensures tasks are performed consistently, forming the backbone of Lean. AI strengthens this by enhancing digital SOPs with real-time compliance monitoring, deviation alerts, and contextual guidance for operators. It doesn’t replace discipline but adds adaptability, ensuring standards evolve continuously as new data reveals better practices without sacrificing consistency.

2. PDCA & Problem-Solving

The PDCA cycle thrives on structured learning, but human analysis alone can be slow with today’s complex datasets. AI accelerates root cause analysis by uncovering correlations across machines, processes, and quality data. Teams can validate problems faster, experiment with solutions confidently, and complete PDCA cycles more quickly, while still respecting Lean discipline.

3. Kaizen

Kaizen thrives on small, incremental improvements identified by workers. AI enhances this process by surfacing patterns humans may overlook, such as subtle energy spikes or recurring micro-delays. Instead of replacing frontline insight, AI provides a continuous stream of data-driven opportunities, helping operators focus on high-impact ideas that deliver measurable improvement over time.

4. Flow & Pull Systems

Smooth flow and pull systems rely on accurate demand and resource alignment. AI strengthens this by forecasting demand patterns, optimizing schedules, and dynamically balancing workloads. The result is fewer bottlenecks, reduced waiting times, and improved on-time delivery. AI ensures Lean pull systems remain responsive even under volatile market conditions or complex supply networks.

5. Visual Management

Lean emphasizes making performance visible so problems can’t hide. AI expands this principle with real-time dashboards for factory that consolidate data across shifts, lines, or even multiple plants. Anomalies are highlighted instantly, escalation paths are clear, and teams can benchmark performance at scale. This extends traditional visual boards into intelligent, connected, and actionable systems.

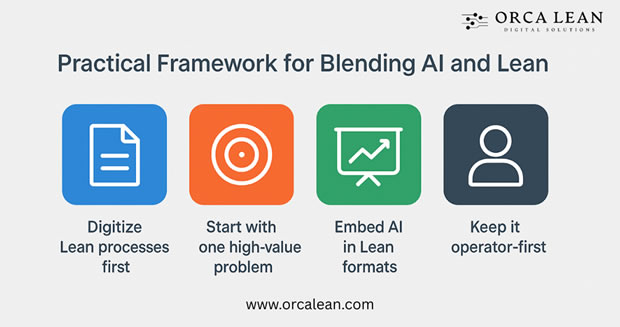

Practical Framework for Blending AI and Lean

For U.S. manufacturers, adopting AI does not mean tearing up existing systems. Instead, it should be a careful extension of Lean practices. Here’s a practical framework:

- Digitize Lean processes first - Before adding AI, ensure SOPs, KPIs, and problem-solving records are digital. This creates a foundation where data flows seamlessly into AI systems.

- Start with one high-value problem - Choose a focused use case like downtime prediction, scrap reduction, or lead-time forecasting. Avoid trying to digitize everything at once.

- Embed AI in Lean formats - Present AI insights within A3 reports, PDCA cycles, or SQDC dashboards. This makes adoption intuitive for teams already familiar with Lean structures.

- Keep it operator-first - AI should support operators, not overwhelm them. Mobile-friendly SOPs, real-time visual alerts, and collaborative dashboards ensure accessibility and engagement.

- Track results with Lean KPIs - Use metrics such as First Time Quality (FTQ), defect rate, scrap cost, and OEE to measure the impact of AI-enabled Lean initiatives.

By following these steps, factories avoid “technology for technology’s sake” and instead ensure that every AI initiative ties directly back to Lean outcomes.

Case Example:

Consider a mid-sized U.S. automotive supplier. For years, Lean practices such as 5S, Kaizen events, and tiered daily huddles had stabilized operations. Quality was strong, but leadership struggled to identify why scrap costs were creeping upward.

By layering AI analytics onto existing Lean systems, the plant discovered a subtle correlation: scrap rates spiked whenever certain raw material batches coincided with specific machine setups. This insight had eluded manual analysis. Once corrective actions were implemented, scrap costs dropped by 18%, while problem-solving cycles shortened by nearly 40%.

The lesson: Lean practices defined the framework, but AI provided the depth of insight needed to accelerate improvements.

Conclusion

Lean manufacturing remains the timeless backbone of operational excellence. It provides the structure, culture, and discipline that no technology can replace. But in an era of vast data and real-time demands, AI acts as a powerful multiplier — giving Lean speed, precision, and scalability.

For U.S. manufacturers, the path forward is clear: blend tradition with technology. By respecting Lean principles while embracing AI’s potential, factories can reduce waste, empower workers, and build resilience in an increasingly complex world.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product