The project required smooth, uninterrupted motion across the record-long dimensions, which the Institute achieved through collaboration with linear motion manufacturer Thomson Industries and automation expert König Lineartechnik.

Custom linear motion solution drives Swiss river restoration research project

Case Study from | Thomson Linear

As part of its initiative to restore the natural functions of anthropogenic impaired rivers, the Federal Office for the Environment FOEN, Switzerland has contracted with the University of Stuttgart Institute for Modelling Hydraulic and Environmental Systems to run a physical model experiment to gain insights into hydro-morphological processes. In the model, a pair of belt-driven linear units move a gantry of sensors across a 67-foot-long bed of scaled sediments to measure hydro-morphological changes for varying hydrological and geometrical conditions. The project required smooth, uninterrupted motion across the record-long dimensions, which the Institute achieved through collaboration with linear motion manufacturer Thomson Industries and automation expert König Lineartechnik.

Project background

The need for the sediment study dates back to more than a century ago when humans started to settle at rivers, and a large share of the population was involved in agricultural processes. At that time, river modifications were implemented to prevent floods and increase arable land. Throughout the decades, larger and larger dams were built to store water and produce electricity. Today, however, as environmental scientists know more about river ecosystems, they have found that measures such as riverbank fixations, damming and river straightening do not always protect from flooding, but disrupt natural habitats and leave a monotonous pattern of rivers. Hoping to reverse the damage, the Swiss federal government policy aims at restoring river ecosystems and their natural functions. Understanding the behavior of sediment transport and river morphology is hence critical to this objective.

Figure 1. The mountainous river located in the Swiss Alps. (Photo by Manuel Nitsche, FOEN)

Sediment. Really?

Sediment plays a crucial role in shaping the river’s physical structures and hence the ecology of a river. It contributes to the formation of various river habitats but may also influence flooding. Sediment and associated nutrients also impact water quality and aquatic life and connects different downstream and upstream regions.

“Bringing rivers back to their natural state requires sufficient sediments, and our role is to help determine just how much sediment is necessary for given hydrological and geometrical boundary conditions. This is challenging because we are dealing with a very dynamic system, with ongoing changes of the riverbed such as erosion, deposition and bank formation,” said Dr. Stefan Haun, who heads the hydraulic laboratory at the Institute.

Equipment design

To model the dynamics of the riverbed, Haun and his team augmented their own experience in modeling hydraulic and environmental systems with reviews of available literature on hydro-morphological systems and visiting other projects. They concluded that they would need a large-scale experiment that would enable investigations of the riverbed before, during and after flooding it with water.

Because of the mountainous Swiss terrains (Figure 1), sediment grain sizes tend to be very coarse there – typically in the 2- to 5-inch range – so they needed the largest model their laboratory could accommodate, which was 67 feet long by 15 feet wide. This enabled the use of natural sediments as bed material, with a mean diameter of 5 mm after scaling. By using a high-precision sediment feeding machine – produced in Switzerland – the model can be fed with sediments. To observe changes in the bed and to monitor the water levels with a high spatial resolution, the team mounted 14 high-precision ultrasonic sensors for point measurements and one laser scanner with a measurement resolution of 0.08 to 0.12 inches for larger spatial areas on a gantry that spanned the 15-foot width of the bed. Two linear units are connected via a cardan shaft and propelled synchronously by a stepper motor to carry the imaging structure across the simulated riverbed.

The project required smooth, uninterrupted motion across the record-long dimensions, which the Institute achieved through collaboration with linear motion manufacturer Thomson Industries and automation expert König Lineartechnik.

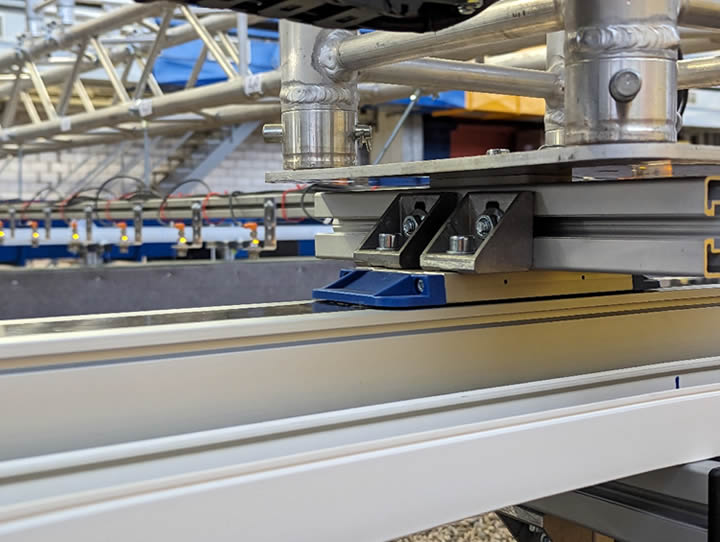

Figure 2: This riverbed simulation uses two custom-designed 67-foot linear units from Thomson that drive sensors in collecting data to form a digital model on riverbed dynamics. (Photo by Bojan Skodic, University of Stuttgart)

The gantry would not have to move extremely fast but would require smooth, uninterrupted motion. This meant that each guide unit, which was delivered in two pieces, had to get end-to-end joint-mounted to a single, backlash-free unit, which would then provide the smooth, uninterrupted movement needed. But there was one problem: no motion control vendor offered a linear unit that met the 67-foot length requirement.

Going to great lengths

Efforts to find linear units long enough to do the job both began and ended with Thomson.

“It was a coincidence that we had seen a label for Thomson’s distributor König Lineartechnik on some of the other linear units used in the laboratory of the Federal Waterways Engineering and Research Institute (BAW) in Karlsruhe, Germany,” said the laboratory electrical engineer Steffen Hägele. “When we contacted managing director Heinz König, we found that there would not be a standard product that long, but that he would investigate with the Thomson engineering department the possibility of building a custom linear unit for this project. Because this would have been a large purchase for us, we set out to get additional bids in line with university policies. However, we could only find one other manufacturer that would even produce such a long linear unit, but at a price that was far outside our budget for this product.”

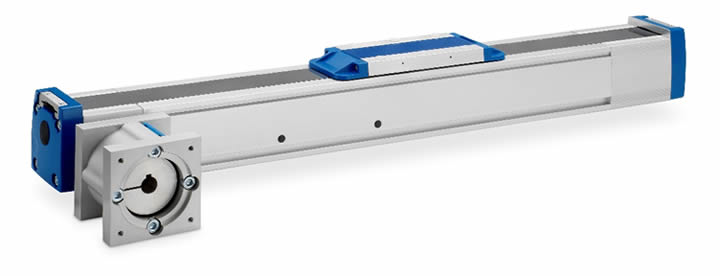

“Due to the long length required, the belt-driven linear unit (Movopart® MG07B) from Thomson was the right option to choose. Though being a challenge, we achieved a safe and cost-effective transport from the manufacturing facility in Sweden to Germany and assembled backlash-free, end-to-end mounted units on site,” added Heinz König.

Configuring a customized system

Thomson based the customization on its Movopart linear guide units, and their engineering team helped configure the units to fit within the application requirements and research budget. (Figure 2) For example, the Movopart units can use either slide or ball bearing guidance, and the team chose a more economical slide bearing as transport-grade precision for the application. The slide bearing would also provide greater dust and moisture resistance. Movopart units can be either belt or ball-screw-driven, and the team also chose the more economical belt-driven model because there would not be high-speed stops and starts in the operation.

Figure 3: Thomson based its custom design on its Movopart MG-B slide-guided, belt-driven linear units.

The final selection was a very long version of the Thomson Movopart MG-B slide-guided belt-driven linear unit, which handles light loads at medium application speeds with low friction. The 67-foot units flank the right and left of the test riverbed to guide sensors. (Figure 3)

Figure 4: The Stuttgart University team arranged fourteen ultrasonic sensors across the gantry, which scans the entire riverbed within 3 minutes.

On the move

At the end of each experiment, an operator manually starts the system, which sets the gantry in motion along the riverbed length.(Figure 4) Meanwhile, the ultrasonic sensors bounce sound waves off the surface of the running experiment, which gives insight into the water levels. After rinsing the water, a second scan is initiated, which provides data on the riverbed. By using these datasets, the research team can evaluate water depths and bed level changes by comparing data sets from previous days.

Completing the digital image of the dynamic state, however, requires a higher spatial resolution of the riverbed, which the researchers get by using just the laser scanner. The laser scanner provides not only a point but works like a camera, providing a high-resolution digital image of the entire scanned area. This gives the researchers the data points they need to triangulate the surface changes digitally. The result is a high-resolution model of the whole surface with some twenty million data points in which the team can analyze and compare many morphological details, including variations in volume for certain parts of the model, bank erosion or sediment deposits.

Keeping the data flowing

The original study design involved modeling hydro-morphological changes over the course of bankfull discharge at different river slopes. However, the data gathering has been going so well that many more insights into the behavior of the system could be gained. Teresa Schnellbach, scientific assistant at the Institute for Modelling Hydraulic and Environmental Systems, will begin publishing the findings soon and will use the gained knowledge for her doctoral thesis.

“We are very happy with our decision to work with König Lineartechnik on this project. The Thomson linear units are doing everything we need them to do, providing the basis for smooth, reliable scans that allow us to integrate accurate data into our analysis software. But there is much more we can use them for in the future. We could, for example, automate measurement operations, move larger loads faster and control them remotely,” said Gerhard Schmid, technical scientific advisor on the project.

For the near future, however, the Stuttgart research team and their Thomson linear units will be well-occupied in data gathering and analyses for this project, and the Swiss government will be getting an increasingly faithful representation of what is settling out in their rivers.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product