The SCADA software technology carries over 30 years of applications in every sector on its shoulders. But what challenges does this technology face in the future?

What will SCADA of the future be like? (Part Two)

Contributed by | Progea

Part 1 of this series can be found here

The new SCADA software technology is ready to face the challenges of the future.

In the first part we talked about how Movicon.NExT came into being.

However, what technology is used in this new SCADA platform?

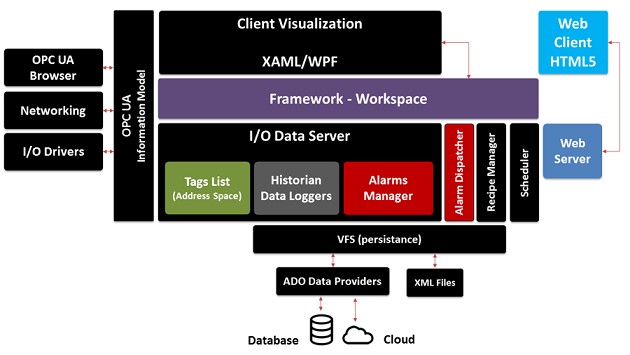

At the base of it all is the framework designed by Progea on the .NET technology with the Plug-in model to make it open to customization and integration of new function models that can be created by expert users. The framework uses the OPC UA information model therefore rendering the infrastructure IEC62541 standard compliant. This ensures that complex data is supported, such as data models that can be defined in PLC systems (IEC61131 e PLC Open) for example, and managed in the platform with the utmost transparency including those with complex structures. Furthermore, any third party application conforming to the OPC UA standard can exchange data directly with the platform’s modules.

Both the Server and Client applications have been integrated in the framework to manage locally or within a distributed architecture. For instance, typically the Server can be run as Windows Servers to which WPF Clients and Web HTML5 can connect. This type of solution makes the platform much more versatile, distributable and scalable than the previous architecture.

Server-Client applications

The platform’s Server is fundamental to applications. Robust and scalable, the Server manages communications with field protocols and performs Gateway e IoT functions. It also manages alarms and all the sophisticated side of data recording using models that are independent from the database format being used locally, in net or in the cloud.

The platform’s Client application is the real flagship. It has been completely designed with the latest generation of Windows Presentation Foundation graphics. The core WPF element is a resolution-independent vector rendering engine that takes advantage of modern hardware component graphics. In addition to this, WPF features a complete set of application developer tools and services which include Extensible Application Markup Language (XAML), controls, data binding, layouts, 2D and 3D graphics, animations, styles, models, documents, multimedia elements, text and typography. WPF is part of the Microsoft .NET Framework to provide a programming model for building applications that incorporate other elements of the .NET Framework class libraries.

Exceptional Graphics for Exceptional SCADA

When using the Movicon.NExT graphics you will immediately understand why the project interface graphics are truly of the new generation. Exceptional graphics, a library filled to the brim with industrial symbols and objects redesigned by Progea to better support WPF graphics quality. Powerful animation, effects, transitions, colours, shading are just to name but a few of the many features available to make graphics a generational leap ahead of the rest. For example, you can import and dynamically animate tridimensional elements and objects for a richer user experience that transports you into new dimension of interactivity in HMI solutions.

Add interactive geographical maps support as well as native support to all the multi-touch functions, just think what designers can truly achieve now what they only could imagine before.

Certainly, you need to take into account that it is not enough just to have the best tools to create your applications. Above all, you need to use graphics programming criteria that caters for both style and usability, as described in the white paper downloadable from the Progea website.

Java? No thank you

The Web Client has also been revolutionized. Due to the increasingly lack of security, configuration difficulty in browsers and evitable sign of the times, the Java technology has been abandoned for HTML5 which is now used as standard technology for the Web. In addition to the graphical interface, the Movicon.NExT Web Client extends its functionality by supporting Web Report and Dashboard managements.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product