This year, the SICK booth will continue to display our Industry 4.0 prowess through live demonstrations of networked sensors and how data can be captured real time and displayed through a dashboard interface. Booth #LS-6419

PACK EXPO Q&A with | SICK, Inc.

Tell us about your company.

SICK, Inc. is a world leader in the production and distribution of industrial automation components. With our worldwide headquarters located in Waldkirch, Germany and USA headquarters in Minneapolis, Minnesota, SICK offers a wide variety of industrial-grade products designed for the factory, logistics, and process automation industries.

Your company will be exhibiting at PACK Expo, what is it that makes this an important event for your company?

As an active member of PMMI, Pack Expo is the largest factory automation industry trade show SICK participates in every year. Many of our customers are fellow exhibitors, which gives us the chance to partner with them by providing equipment for booth displays and participate in co-marketing activities to hopefully sell more machines. This show also gives SICK the opportunity to differentiate itself by exhibiting our capabilities to help drive and support Industry 4.0 efforts throughout the factory automation industry.

What makes your booth a must visit for PACK Expo Attendees?

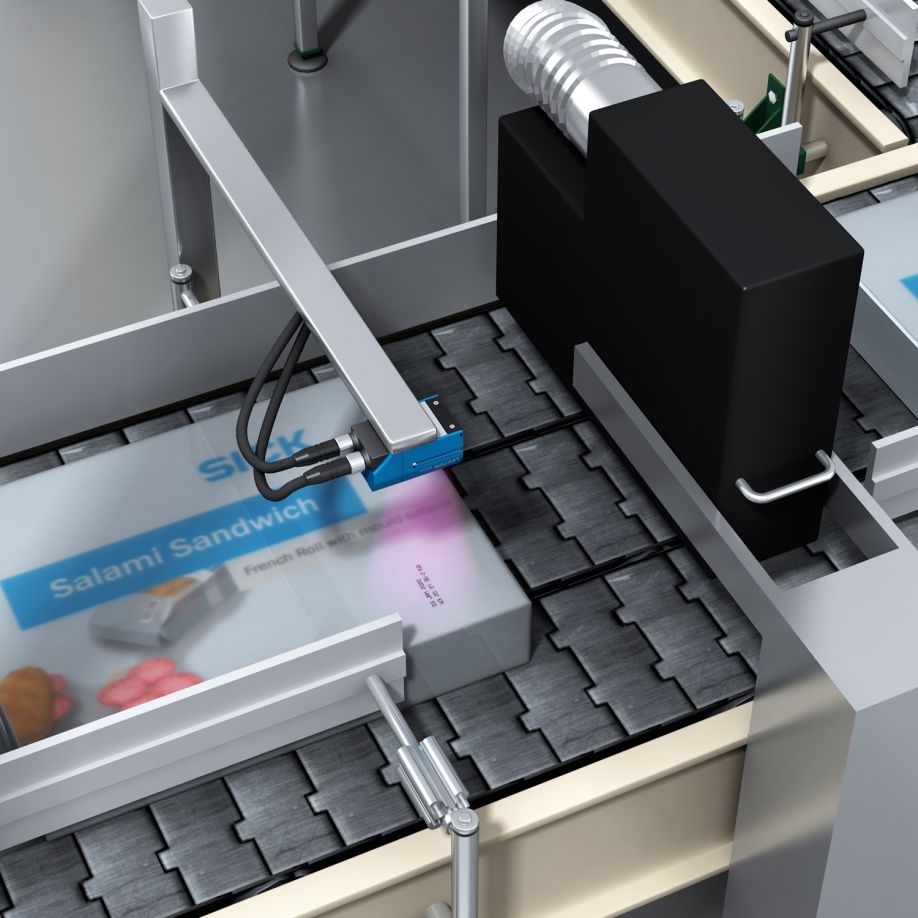

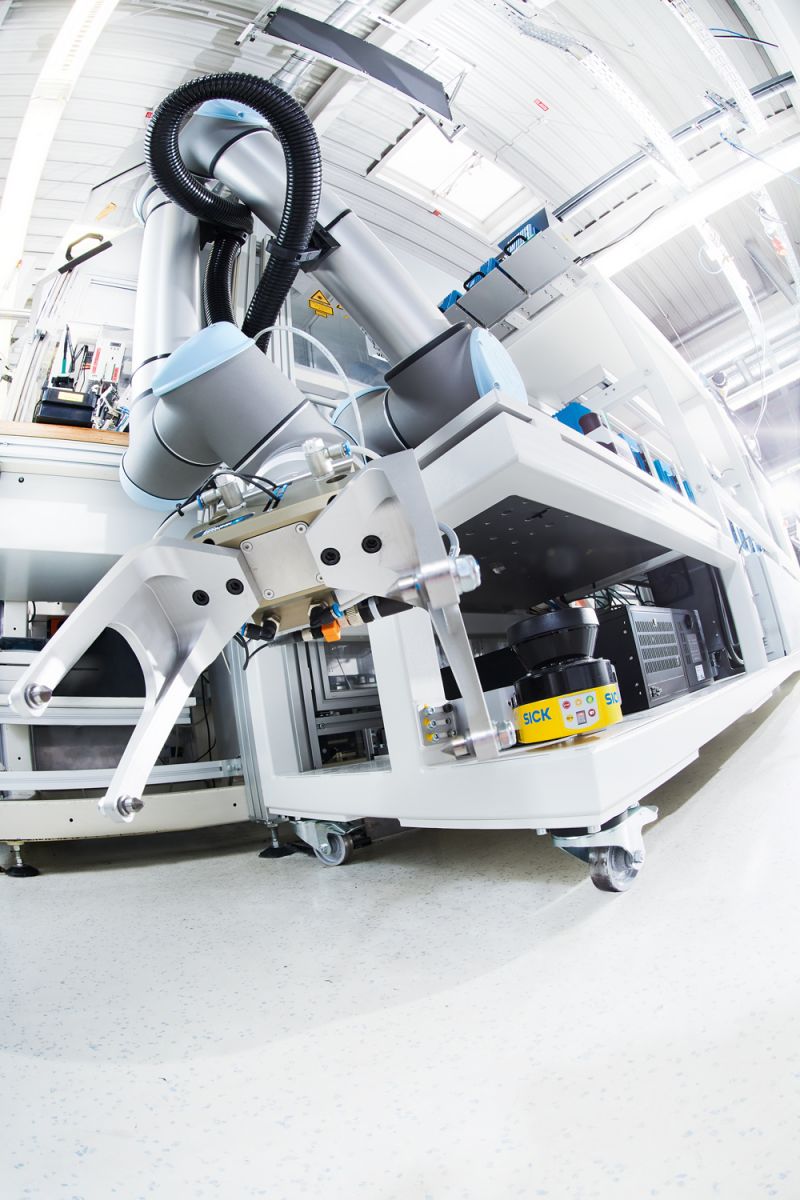

This year, the SICK booth will continue to display our Industry 4.0 prowess through live demonstrations of networked sensors and how data can be captured real time and displayed through a dashboard interface. We will also present solutions for the ever-growing use of robots in the packaging industry and how they can safely interact alongside human workers, while maintaining productivity and uptime. The continuing issue of product recall and error proofing will be addressed by demonstrating the most powerful optical character recognition (OCR) capabilities seen to date through the partnership between SICK & AutoCoding Systems.

PACK Expo has many educational sessions, forums & Demo’s, is your company involved in any of them this year?

SICK will feature two live presentations on the Healthcare Packaging Expo Innovation Stage, located in the North Hall. On Monday, September 23 at 2 p.m., Steve Winski, SICK’s Consumer Goods National Sales Manager and Mike Hughes, AutoCoding Systems’ Managing Director, will present, “How to Drive Efficiency & Prevent Waste or Recalls in Your Packaging Line.” This session will explore a unique solution that provides error proofing of primary & secondary packaging lines in order to prevent product recalls, rework, and waste.

On Tuesday, September 24 at 11 a.m., Ron Stuver, Director of Business Consulting Industry 4.0 for SICK, will give a 30-minute presentation entitled, “Industry 4.0: Make it Real.” This will explain how Industry 4.0 is not a technology in and of itself, but rather a concept of how automation can be better utilized to help companies achieve operational goals that are aligned with business strategies.

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions, pavilions etc. you plan on attending?

I am looking forward to seeing the newly formed Robotics Zone that will be at Pack Expo for the first time this year. With the packaging market continuing to grow and evolve, the use of robotics will do the same and SICK needs to continue to be an automation solutions market leader in anticipation of this robot emergence. Seeing firsthand the ways robots will interact with the packaging sector of automation should provide crucial insight for future product and solution innovations.

The factory floor is undertaking rapid advancements, be it automation, robotics, machine vision or data. Automation Technology is a huge part for many manufacturers, give us an idea on how your company and product is being utilized now in the smart factory.

This is a difficult question to answer because SICK is in so many facets of the modern day smart factory! We are honestly involved in everything on the factory floor, from the sensor level (IO Link, edge computing, recipe management) to the network level (providing data to the cloud, network gateways) and everything in between! In fact, last year at Pack Expo, our main exhibit was titled the Smart Factory where we featured our products working on an AGV, safety controls for a marking laser, vision inspections for finished goods, and collaborative robot safety. This year, we will feature a lot of these same solutions on different exhibits throughout the booth.

Give us your thoughts on what the future holds for manufacturers and automation technology.

In short, the future is bright. Automation will continue to drive costs of finished goods down while increasing productivity and uptime. This will incentivize manufacturers to discover new and exciting ways to apply automation into their workflows. This will also allow the workforce to move away from lower-skilled, lower-wage occupations and become a greater asset to their employers by increasing salaries and the buy-in to the work being done. Add to this, expanding human-robot collaborations and Industry 4.0, and the sky is the limit!

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product