Some robot movements can be realized with rotors, but most of them work better with linear actuators. If you have drives with programmable positioning, you can create a precise machine useful for a number of tasks.

Linear Actuators with Programmable Positions

Linear Actuators with Programmable Positions

Contributed by | Progressive Automations

Electric linear actuators have become a part of our casual lifestyle a short while ago. The most popular actuator applications still include mostly heavy industrial work, oil and natural gas extraction, and other hazardous lines of work. However, tech optimization and miniaturization have made the actuators available for virtually any use in our everyday life.

Be as it may, actuators differ in major ways depending on the task they are made for. You would need to thoroughly analyze your project to choose the right actuator model, as most of their parameters cannot be altered. The stroke of your drive is one of the criteria that can be changed. Here is why it is important and how exactly you can change it.

Why You Might Need to Have an Actuator with Altering Stroke

In the early days of linear actuators (back when they were pneumatic or hydraulic), controlling their movement was a challenging task. If you needed to move an object at a different speed or to a different distance, you would need to use different drives, even if the movement needed to be in the same direction.

Nowadays, the versatility of a single actuator is much higher. With the help of additional tools (in some cases, even without them) you can use one device to transfer objects to separate positions, lift something to a different level depending on its mass, regulate the position and speed of the actuator with an incredible degree of precision.

Having more freedom when it comes to actuator positioning is always great, but it is especially helpful if you’re interested in robotics. Some robot movements can be realized with rotors, but most of them work better with linear actuators. If you have drives with programmable positioning, you can create a precise machine useful for a number of tasks.

How to Achieve an Altering Stroke in a Linear Actuator

While most of the parameters of an actuator can’t be changed, there are several different ways you can adjust the stroke length. The most prominent ones are:

1. Buying a Model with a Pre-programmed System

A recent addition to the market, linear actuators with built-in controllers are effective and easy to use. Most of them are 12-volt linear actuators, but there also are 24-volt options. It’s the best option for novices, as it is still rare and limited in some aspects.

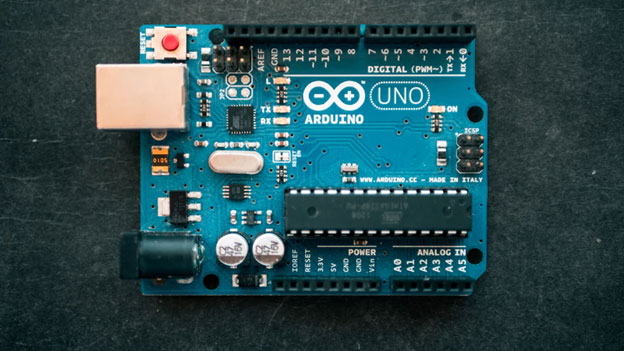

2. Using a Microcontroller

Systems like Arduino provide a high level of customization specific to your particular task. You need to have some experience to use it, but it applies to a wide range of actuators.

3. Employing External Limiting Hardware

Specially made limit switches are also a viable option, especially if you don’t need to make the change very often. It’s a cheap and less sophisticated option, but it is effective.

In Conclusion

An electric actuator is a flexible tool, and adding more control options to it makes it even more valuable. Furthermore, it provides a great playfield for a user to play around with and create something unique. So, don’t waste your time and try out 12-volt linear actuators with programmable positions for your project.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product