Booth #134638. CGIs custom gearbox is used to drive the spindle onboard JPLs latest coring drill test unit for the Mars 2020 mission.

Contributed by | CGI, Inc.

Tell us about your company.

CGI, Inc. was founded in Southern California as “California Gear and Instrument” in 1967 by Don Snow. As a fledgling gear design and manufacturing company, CGI soon developed a reputation for quality products and innovative solutions, particularly in the medical and aerospace industries. Garnering customers such as Jet Propulsion Labs and Hall Surgical, CGI continued to grow and in 1990, Don Snow decided to move the business to Carson City, Nevada. Upon this move, the California Gear and Instrument name formally evolved into “CGI, Inc.”. Shortly thereafter, CGI became a pioneer in providing standard industrial gearbox solutions along with the established OEM component products that CGI had provided for decades. In the late 1990s, CGI expanded its facility and in 2006, Mike Madison and Brian Coclich purchased the company from Don Snow. Despite the challenges of the recession, Mike and Brian have taken the company to new heights making CGI a strategic partner for customers along a broad spectrum of industries.

Your company will be exhibiting at IMTS, what is it that makes this an important event for your company?

We have limited our shows to two per year. IMTS gives us the biggest exposure to as many potential and existing customers as possible in one location

Highlight a 2 or 3 products you will be showcasing at the event?

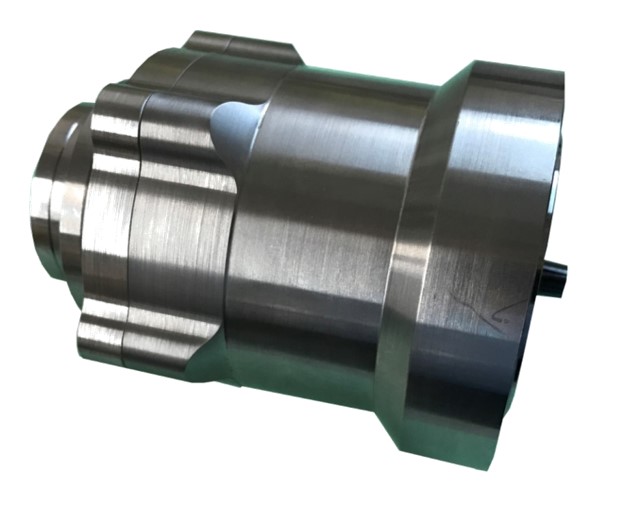

CGI’s custom gearbox is used to drive the spindle onboard JPL’s latest coring drill test unit for the Mars 2020 mission.

The gearbox’s dual-output interface provides the ability to switch between the high speed needed to drill and a secondary mode that provides high torque for isolating and extracting samples. JPL utilized CGI’s engineering support to design and fabricate this fully-customized, dual-output gearbox to meet all performance and interface requirements.

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions you plan on attending?

Most interested to see: new technology and robotics. No education programs at this time.

When you book a booth for a tradeshow like this what are your expectations and what does your company hope to accomplish at the event?

To forge new relationships that turn into new business. Also to meet old business partners and strengthening those relationships.

A tradeshow of this magnitude is extremely busy and stressful for the staff of exhibiting companies. Any fun things or places your team can suggest in Chicago to help unwind?

Wrigley Field for a Cub's game!

Featured Product

CGI Motion - Advanced Products for Robotics and Automation

From Prototype to Production CGI Motion enables design excellence across a wide range of industrial applications. We thrive on customer driven innovation in precision gearbox, precision machined components and electro-mechanical assembly solutions ranging from aerospace systems to semiconductor applications. We are your design and manufacturing partner helping to differentiate your product, machine or innovation. Our team of problem solving engineers and product managers can bring your application to market on time and under budget. Whether it's an improvement on a current design or groundbreaking new designs, CGI has the know-how and team to enable design excellence. Connect with us today to explore what CGI Motion can do for you.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product