New thermal protection technology for large industrial/commercial HVAC and refrigeration systems, heavy duty transportation, conveyor belts, assembly lines, medical, energy and other complex manufacturing systems.

How Integrated Thermal Protection Technology Can Prevent Solid State Relay Failure in Industrial Systems

Rogelio Castañeda and Oscar Rivera, | Sensata Technologies

What do large industrial/commercial HVAC and refrigeration systems, heavy duty transportation, conveyor belts, assembly lines, medical, energy and other complex manufacturing systems all have in common? Motors. Big and expensive electrical motors that, if they overheat, can be damaged or even destroyed. Most large motor driven machinery requires a system attached to the motor’s power supply that will sense overheating and turn off the motor to prevent this damage. In many cases, this device is an electrical relay that turns power on and off. There are two main types of these relays – electro-mechanical (EMRs) and solid state (SSRs).

EMRs Versus SSRs

For over 50 years, electro mechanical relays were the “go to” solution for managing load circuits. However, in the last decade or so, solid state relays have taken a great deal of the market share.

There are significant differences between EMRs and SSRs, especially in terms of life-span.

EMRs are mechanical based and have moving parts, making them highly susceptible to magnetic noise, vibration, shock and other outside influences that can affect wear and life cycle. In contrast, SSRs offer a durable, all-solid state electronic construction with no moving parts to affect wear or accuracy, thereby offering predictable operation and longer life. The average lifespan of electro-mechanical relays is in the range of 100-500K cycles compared to 2 million life cycles of solid state relays. With such durability, SSRs often outlast the equipment in which they are installed.

In addition to a longer life span that provides greater reliability and replacement cost savings, SSRs provide faster switching than EMRs, making them adaptable to a wider range of high power load applications. They operate silently (without the undesirable clicking sound emitted by EMRs) with low input power consumption and produce little electrical interference. Both shock and vibration resistant, SSRs can withstand harsh environments and continue to operate accurately and reliably, whereas EMRs need frequent replacement, making them very undesirable in harsh conditions.

SSRs excel over EMRs in other areas as well. They are compatible with control systems, immune to magnetic noise, and are completely encapsulated. Their solid state design makes them position insensitive and provides design engineers more flexibility to mount SSRs anywhere within an application– whether sideways or upside down. SSRs can be installed in places where there is heavy vibration with no interference in performance, whereas mechanical-based EMRs are very sensitive to positioning, shock and vibration, thereby restricting design options.

With all the advantages that SSRs provide, it is understandable that they are more expensive than EMRs. Though significant, this price point disparity becomes a nonissue when factored in over the 2 million life cycles SSRs provide.

THE THERMAL MANAGEMENT CHALLENGE

As SSRs consume power whether open or closed, there is a thermal management component to their operation, just like the motors that they control. Should overheating occur, diagnosing and replacing a damaged SSR can take time while the assembly line or manufacturing system is down and out of service, running up even more costs.

To illustrate how an SSR operates, consider the product’s use in commercial refrigeration applications in the building equipment market. In a refrigeration application, the SSR’s function is to turn the compressor on or off to keep the system temperature within a specified range. The input control might be from 90-280 AC with a required tripping temperature set at 95°C. A buffer is engineered into the circuitry using a variety of components to ensure that the desired tripping action occurs.

Solid state relays like Sensata’s 53TP Series offer long operational life of over 2 million cycles and can withstand harsh environments found in many industrial systems.

When the SSR turns on to generate current, it also generates heat. If the heat causes the temperature to exceed the product’s particular semiconductor limit, a number of problems can occur, such as:

• SSR can short-circuit and cause fire and human injury

• SSR can be damaged and shorten the lifespan of the semiconductor as well as the entire system

• System can shut down completely

NEXT GENERATION SOLID STATE RELAYS

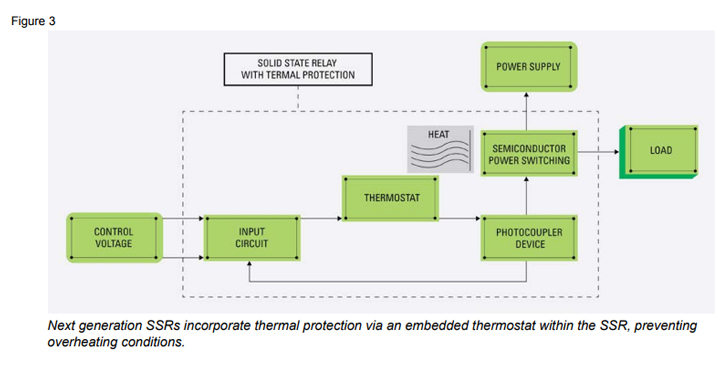

To address the overheating challenge, Sensata has developed a new and unique SSR technology that integrates a thermostat into the SSR itself to ensure that the relay always operates in a safe or protected mode. This gamechanging design incorporates all the advantages of standard SSR technology, but is differentiated by its ability to prevent the SSR from overheating, thus protecting component and system operation from potential damage or shut down.

The new SSR cuts off input circuit power when the temperature goes beyond the specified maximum as determined by the application requirements. Power is automatically turned on again when the temperature has cooled down to within the normal operating range.

This automatic thermal protection is accomplished by means of an integrated thermostat embedded in the SSR. The thermostat senses the internal temperature of a mechanical interface with a metal plate where the internal powerswitching device is mounted. If the heat exceeds the normal range, it sends a signal to the SSR to turn off the power. This built-in thermal protection completely prevents overheating conditions by providing a trip before equipment damage can occur, thereby saving time, money and preventing potential injury.

In addition to preventing overheating, the integrated thermal protection function can troubleshoot design issues in the system. It can help identify incorrect heat sinking capacity in the SSR or system, poor installation resulting in insufficient heat sinking contact, heat dissipation efficiency of the system, as well as other issues. This provides a valuable tool to the engineer responsible for the system’s operation.

While developed for use in a commercial refrigeration application, these new SSR designs can be adapted to other industrial and manufacturing applications to provide similar system benefits. For example, consider a conveyor belt application where a motor could stick and cause overload and potential damage to the system.

In this case, the SSR with integrated thermal protection would prevent overheating from occurring by shutting down the conveyor belt as soon as a pre-determined heat threshold was met within the SSR’s thermostat. In injection molding applications where limited space can cause the temperature in the cabinet to rise, thermal protection prevents the SSR from overheating if the heatsinking is not adequate, thus avoiding costly repairs. For heating systems, the thermally protected SSR can help shut down the heating element if there is a problem with the temperature controller that causes a temperature runaway, thereby protecting the entire system.

WHAT’S NEXT? THERMALLY PROTECTED “SMART” SSRS WITH DECISION-MAKING CAPABILITIES

Sensata engineers are working to develop thermally protected SSR technology with even more built-in functionality ‒ giving new meaning to the term “smart SSRs”. This technology incorporates a microcontroller with firmware specific to the desired internal trip temperature that activates a decision from the pre-programmed software settings. With a decision-making capability inside the SSR package, protecting motors and systems from over-heating and breakdown will be more automated than ever.

Since the 1970s, traditional solid-state relays have offered a proven electronic switching solution for a variety of applications, providing a longer lasting, more versatile, flexible and robust solution than electromechanical relays. For the first time, new solid-state relays featuring integrated thermostats can prevent overheating and identify heat sinking issues to help improve system safety, efficiency and longevity. This product evolution will undoubtedly change the game in thermal protection for a wide range of applications.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product