The world of industry has been steadily advancing since the beginning of the Industrial Revolution, and this new move toward data-driven manufacturing strategy is simply the next step in revolutionizing the industry.

The Role of Big Data in Industrial Manufacturers' Growth

Kayla Matthews | Productivity Bytes

Big data is a buzzword that has shown up everywhere from industrial manufacturing to healthcare. In essence, it gives companies a way to use all the data they’ve been collecting for years to improve their business practices.

It would take human beings decades to sort through all the data that has been collected in the manufacturing industry just over the last 10 or 20 years — and even then, there is no guarantee they’d be able to make any connections or find any patterns.

Big data changes that by employing machine learning and predictive analytics. What role will big data have in the future of industrial manufacturing growth?

The IIOT (Industrial Internet of Things)

The Internet of Things is making its way into nearly every home — smart devices from televisions to garage doors to fridges are all making everyone’s lives easier by connecting everything in their home. While industrial manufacturing plants might not be installing smart fridges, they can still benefit from the IOT with their own Industrial Internet of Things.

The IIOT allows manufacturers to save money and improve efficiency in a variety of ways, including:

-

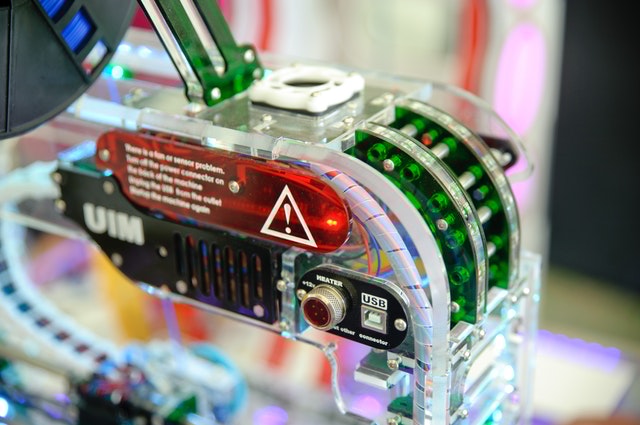

Predictive maintenance — These smart machines can both alert their handlers when a problem has occurred, and use past experiences to predict when preventative maintenances should be performed to prevent problems from occurring in the first place.

-

Industry Predictions — Many industrial manufactures plan their production on the year based on the previous year’s numbers. While this can be moderately accurate, it doesn’t take into account changes that might happen in the coming year. Utilizing predictive analytics can enable the manufacturer to make accurate predictions about the coming year.

-

Neural Network Techniques — This is an advanced form of analytics that is based on the way the brain works, and it can be used to examine things like how production input affects overall production yields, enabling industries to improve their manufacturing processes from experience.

By improving production processes, companies can improve their overall production by reducing overhead costs, reducing waste and improving their overall yield.

Establishing a Data Management Platform

The key to the successful application of big data in the manufacturing industry is the building of an efficient data management platform. Also known as a DMP, this platform helps you gather information, process it more effectively and accurately make decisions based on that data in an informed way.

A DMP can require a lot of time, and in the beginning, it can require a something of an investment to get all the equipment and training that is required to keep these systems running smoothly. It can be challenging if not implemented correctly or if there aren’t enough knowledgeable people on staff to keep your DMP running.

The most important part of setting up a DMP is getting it right the first time, even if that initial implementation takes longer than you originally anticipated. A poorly set up data management platform will only end up costing you more money and impeding your production capabilities in the long run.

Once the DMP is set up, take the time to hold frequent reviews to make sure the platform is running smoothly and is actually benefiting your business. If things are falling by the wayside or advances aren’t where they should be, reassess and figure out the best way to make your data management platform work for you.

The world of industry has been steadily advancing since the beginning of the Industrial Revolution, and this new move toward data-driven manufacturing strategy is simply the next step in revolutionizing the industry.

Many experts believe that due to this trend toward big data, we’re in the midst of the 4th Industrial Revolution. Smart machines and the IIOT will carry us forward into the future.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product