Smart Manufacturing 4.0: AI-Driven Operations in Emerging Markets

How Artificial Intelligence is Empowering Agile, Sustainable Growth in Developing Economies

It's a seismic shift in the global manufacturing paradigm. While Industry 4.0 technology, particularly artificial intelligence (AI), machine learning, and industrial IoT, has been hyped in Western markets over years, a quiet revolution has been building in emerging markets. In India, Southeast Asia, smart manufacturing has been getting its roots, not merely as catch-up with global norms, but as a leapfrog opportunity to redefine industrial greatness.

At its center, this shift involves the convergence of AI with conventional manufacturing processes. In new markets, where infrastructural gaps, labor-oriented structures, and unpredictable supply chains commonly prevail, AI presents an influential tool with the potential to catalyze precision, speed, and sustainability.

The Ground Realities in Emerging Markets

Emerging markets are both challenging and opportunity. Outdated equipment, inconsistent data acquisition, insufficient skills, and prohibitive costs of operation are among typical challenges. These, however, are increasingly prompting innovation.

Compared with mature markets burdened with sunk costs in aged infrastructures, many Indian, Indonesian, and Vietnamese firms are opting for cloud-native, AI-first approaches from the outset. The “blank sheet of paper” approach lets them benefit sooner from predictive analytics, digital twins, and automated production lines. Moreover, government initiatives like India’s “Make in India” mission and National AI Mission provide significant tailwinds in favor of manufacturers looking to take advantage of transformative technology.

AI as the Central Nervous System of Modern Manufacturing

In the modern smart factory, AI plays the role of the central nervous system--observing streams of data coming off equipment, decoding abnormalities, and making real-time prescriptions. It's not about replacing workers; it's about enabling them.

Consider predictive maintenance, for example. In areas where downtime has the potential to immobilize production for days, AI-powered models are able to forecast machine failure before it occurs, preventing lost productivity worth millions. An Indian automotive parts manufacturer minimized unplanned downtime by 30% with the help of a mere machine-learning algorithm trained with sensor information from CNC machines.

Another important application involves quality assurance. AI-enabled, computer vision technology will read parts at speeds and degrees of precision beyond human limits. Technology spots tiny defects in real-time, substantially increasing yield without increasing the cost of inspection labor.

Democratizing Manufacturing Excellence

What’s really innovative about AI in new markets is its ability to democratize excellence in manufacturing. Cloud-enabled AI solutions and open-source technology have brought down the cost barrier for small and medium-sized businesses (SMEs). With an adequate data infrastructure in place and reasonable spend, even tier-2 suppliers in far-flung industrial belts can tap into the digital capabilities that large, multi-national OEMs use.

In addition, mobile-first AI dashboards along with voice-enabled applications in vernacular languages are empowering non-technical operators to interact with smart systems effortlessly. This people-oriented approach to digitalization guarantees that frontline workers do not get isolated in haste toward automation.

Building Resilience Through AI-Driven Supply Chains

Traditionally, supply chains were evaluated primarily through efficiency metrics. However, today’s increasingly complex and unpredictable environment has elevated the role of the supply chain—not only as a driver of business success but also as a key element of a company’s differentiation strategy. To navigate heightened volatility in both demand and supply, as seen during the pandemic, supply chains must evolve to become more resilient. A resilient supply chain can respond swiftly and recover effectively from unforeseen disruptions. New markets tend to experience unpredictable supply chains because of rising geopolitical tensions, supply corridor bottlenecks, or raw material scarcities. AI allows businesses to react with speed. Advanced predictive algorithms are able to process past data, seasonal patterns, and even macroeconomic trends to better forecast demand. Integration of physical assets to digital tools enables shop floor events to enterprise business processes with closed feedback loop between production planning and execution.

This was the case with the COVID-19 pandemic, when Indian drug firms employed AI in reshaping supply chains and scaling up supplies of essential drugs. By modeling various procurement and manufacture situations, the firms were in a position to ensure continuity amid disruptions across the world.

Sustainability and Efficiency: A Dual Mandate

Energy prices in most emerging markets are higher than they should be. By optimizing energy use, cutting down energy wastage, AI contributes greatly to sustainability objectives. Smarter energy management technology has the ability to read consumption trends and make recommendations about adjustments in operations, lowering energy consumption 10–20%.

In water-stressed locations, AI also helps monitor use of water, detection of leaks, and adherence to environmental permits in manufacture facilities. These processes are not merely about compliance—they help corporate reputation as well as global market competitiveness where criteria around ESG (Environmental, Social, Governance) are becoming an important factor.

Workforce Transformation: Human + Machine Synergy

Arguably the most under covered area of AI-driven manufacturing innovation is the evolution of the workforce. Instead of making workers redundant, Industry 4.0 is providing new jobs—data interpreters, robot trainers, digital maintenance technicians—particularly in large technological talent pools like countries.

To realize this potential, however, companies require investment in upskilling. Industry-academia collaboration and public-private partnerships are emerging in Southeast Asia and India to get workers ready for AI, data analytics, and human-machine interaction. The future factory isn't workerless but smart and inclusive.

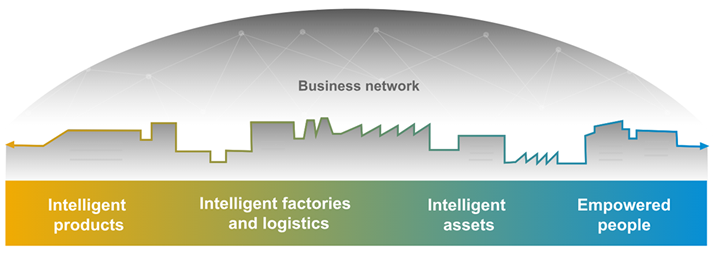

Figure Source: Winning Strategic Initiatives by SAP

Barriers to Scale—and the Path Forward

Despite the promise, it's tough to scale AI adoption across emerging markets without dismantling major barriers: data silos, cybersecurity, lack of funds, and resistance to change. A step-by-step approach, however, starting with pilot projects, demonstrating quick ROI, and gradually building digital maturity—has succeeded.

Policies of the government should also adapt to promote interoperability standards of data, AI ethics, and industrial cybersecurity. Industry leaders should also undergo a paradigm shift—cost-oriented automation to value-oriented transformation.

Conclusion: A New Global Manufacturing Order

Emerging markets are going from being merely passive players in global supply chains to innovation centers. Led by AI, smart manufacturing isn’t merely an option, it’s a necessity.

By incorporating AI into the very essence of operations, new market manufacturers can bypass old constraints, create sustainable and agile businesses, and set the new world standard of excellence. The era of Smart Manufacturing 4.0 has arrived—and its strongest narratives are emerging where you least expect them.

I, Tejas Vaidya, have brought over 16 years of experience in Enterprise Resource Planning (ERP) IT implementations and global roll outs, with a focus on applying industry specific supply chain solutions to modernize ERP technologies through SAP APO (Advanced Planning and Optimization), SAP S4 HANA, SAP IBP and SAP ECC. As a Sr SAP APO/S4 HANA Consultant/Solution Architect, my cross-industry impact spans to various industrial sectors like Pharmaceuticals, Automotive, Food & Beverages, and medical device manufacturing, where I have consistently delivered operational improvements through digitization and IT transformation of legacy systems into efficient, transparent and user-friendly solutions targeted for Advanced Production Planning & Scheduling, Supply Network Planning as well as Demand Planning/Forecasting functions including AI-driven automation and smart digital platforms.

By integrating renowned ERP systems offered with AI, Machine Learning and cloud-based technologies, along with business specific custom enhancements/developments to address complex supply problems, I have enabled measurable outcomes for several Fortune 500 companies.

Featured Product