New 3D Printing Technique Significantly Strengthens Materials

Kenny Walter for R&D Magazine: A major hurdle regarding 3D printing may soon be overcome.

Kenny Walter for R&D Magazine: A major hurdle regarding 3D printing may soon be overcome.

Researchers from Texas A&M University have strengthened 3D printed parts by applying traditional welding concepts to bond the submillimeter layers in a 3D printed part together.

“I was able to see the amazing potential of the technology, such as the way it sped up our manufacturing times and enabled our CAD designs to come to life in a matter of hours,” Brandon Sweeney, a doctoral student in the Department of Materials Science and Engineering at Texas A&M, said in a statement. “Unfortunately, we always knew those parts were not really strong enough to survive in a real-world application.”

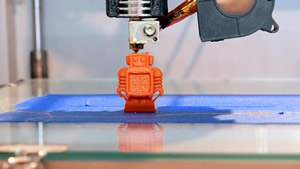

Objects printed with a 3D printer are comprised of several thin layers of materials—often plastics—deposited on top of each other to form a desired shape. However, the layers are prone to fracturing, which causes issues with the durability and reliability of the part when used in real-world applications like a custom printed medical device.

“I knew that nearly the entire industry was facing this problem,” Sweeney said. “Currently, prototype parts can be 3D printed to see if something will fit in a certain design but they cannot actually be used for a purpose beyond that.

“The basic idea is that a 3D part cannot simply be stuck into an oven to weld it together because it is plastic and will melt,” he added. Full Article:

Featured Product