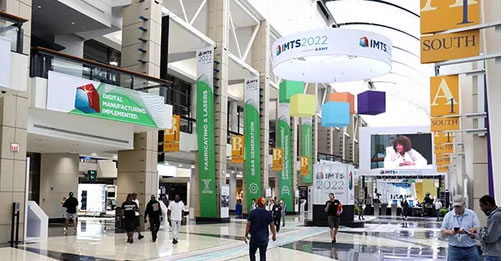

IMTS 2022 Opens Sept. 12, Showcases Digital Tech That Address Manufacturing’s Biggest Challenges

Manufacturing is back, and Chicago will be the epicenter, as an estimated 90,000 people will attend IMTS – The International Manufacturing Technology Show, which runs from Sept. 12-17 at Chicago’s McCormick Place. IMTS is the largest manufacturing technology show in North America. With more than 1.21 million square feet of exhibit space representing 1,815 exhibitors, the show features digital technologies that offer the fastest and most efficient means of solving the challenges faced by manufacturers and their suppliers.

Nine technology pavilions feature solutions such as multi-tasking machining centers, robots/cobots, digital twin, manufacturing software, controls, additive manufacturing, and quality control/inspection. More than 75,000 people have preregistered for the show, which attracts OEMs, tier suppliers, contract manufacturers/fabricators, jobs shops, sourcing/purchasing agents, investors, students, and technical educators.

“The advances in digital manufacturing technology on display at IMTS 2022 will amaze even industry veterans,” says Peter R. Eelman, chief experience officer at AMT – The Association For Manufacturing Technology, which owns and produces IMTS. “If OEMs and job shops can digitize it, they should. Digital tech is the best way to increase productivity with an existing talent pool, control costs, make reshoring/near-shoring more attractive, reduce time to market, and respond with agility to volatile markets.”

Eelman notes that the affordability and ease-of-implementation now puts advanced solutions within reach of small and medium-sized businesses.

“IMTS exhibitors have blown away existing barriers to technology acquisition,” says Eelman. “For example, visitors can learn how to set up and run an entry-level automation solution in 30 minutes. Computed tomography inspection systems now operate with almost push-button simplicity, and digital twin technology is as easy to use as your favorite CNC control or CAD/CAM program.”

Keynote Presenters

Highlights of the show will include keynote conversations on the IMTS+ Main Stage in the Grand Concourse with industry luminaries at 9:30 a.m. Featured speakers include:

- Monday opening ceremony: Douglas K. Woods, president of AMT, and Dr. Jochen Koeckler, chairman of the managing board of Deutsche Messe AG, Hannover, Germany (the HANNOVER MESSE USA Conference is co-located with IMTS).

- Tuesday: Stephen Hooper, vice president of design and manufacturing at Autodesk.

- Wednesday: Barbara Humpton, CEO of Siemens USA, and Tim Shinbara, chief technology officer at AMT.

- Thursday: Manufacturing USA network speakers Dr. Diana Bauer, acting deputy director of the Advanced Manufacturing Office within the Office of Energy Efficiency and Renewable Energy at the Department of Energy; Tracy Frost, director of the Department of Defense Manufacturing Technology Program; Mike Molnar, founding director of the Advanced Manufacturing National Program Office; and John Wilczynski, executive director at America Makes.

- Friday: Dr. Jeffry Ahrstrom, CEO of Ingersoll Machine Tools.

Additional IMTS+ Main Stage presentations include a conversation with Andrew Crowe, founder of the New American Manufacturing Renaissance, and Dr. Onome Scott-Emuakpor, founder of Hyphen Innovations, about their journeys into manufacturing and engaging underserved communities; the National Metalworking Reshoring Awards winners presentation; and a conversation on using robotics to solve manufacturing challenges, featuring executives from Knapheide, FANUC America, Acieta, SCHUNK, and Silicon Valley Robotics.

Visual Attractions

On Wednesday at 9:30 a.m., 11:30 a.m., and 1:30 p.m. at the McCormick Place Square entrance, manufacturer, technologist, and founder of Gravity Industries Richard Browning will fly his patented Jet Suit over McCormick Square. The Jet Suit relies heavily on 3D-printed parts that conserve weight. On Thursday at 2:00 p.m. on the IMTS+ Main Stage, Boston Dynamics will discuss mobile robots in manufacturing and feature Spot, the famous quadruped robot dog.

AMT’s Emerging Technology Center (ETC), located at the entrance to the North Building, will feature a scaled section of the 23-foot-tall Rosenberg Space Habitat, the world’s tallest 3D-printed polymer structure. The ETC will also feature live demonstrations of the robotic 3D printing technology used to make the space habitat and the manufacturing technologies being used to create the 138-foot-tall Giant Magellan Telescope. IMTS exhibitors Ingersoll Machine Tools (booth #338004) and Siemens Industry (booth #133346 and #433028) collaborated to produce the space habitat, and Ingersoll is machining the telescope mounting system at its facilities in Rockford, Illinois.

Specialty Programming

The Smartforce Student Summit at IMTS will attract approximately 9,000 STEM students, including thousands each day from Chicago-area schools. It features more than 60 exhibitors that represent a who’s who of manufacturing technology leaders who will provide interactive demonstrations with a heavy emphasis on automation and virtual reality. Presentations in the Smartforce Theater offer professional development sessions for educators.

IMTS also offers a multitude of educational conferences and networking events designed to appeal to highly diverse audiences. Highlights include:

- The AM4U Stage presented by Formnext, a new event for IMTS, will feature daily presentations on adopting industrial AM into production processes, as well as entrepreneurship and business models. AMT and Gardner Business Media have collaborated with the organizers of Formnext to launch the Formnext Chicago event in spring of 2025.

- The Women Make Manufacturing Move luncheon and reception, both with a full panel of presenters.

- The Job Shops program, which covers such topics as talent retention, taking the traditional job shop digital, marketing, 3D printing for job shops, and the Top Shops award winners and benchmarking program presented by AMT and Modern Machine Shop magazine.

- The Smarter Sourcing Symposium for supply chain strategies.

- The Additive Manufacturing Conference by Gardner Business Media.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product