How Small Manufacturers are Building a Business Case for Robotics

Smaller manufacturers are the fastest-growing area of industrial robotics today, driven by the need for new collaborative robotics systems.

EU Automation publishes new guide: How to Get Robotics Right - Avoiding the Common Costly Mistakes of Automation Adoption

The useful guide provides engineers with valuable information about how to introduce automation into manufacturing practices successfully, so they can realise the full potential of robotics

Breaking down Walls to Build e-Factories

Thomas Burke, Global Strategic Advisor at CC-Link Partner Association (CLPA), looks at how industrial automation vendors, machine builders, and end users can futureproof robotic systems with value-adding network technologies.

Is RaaS the way to go?

Back in 2017, the International Data Corporation (IDC) predicted that 30 percent of commercial robotic applications will be in the form of Robots as a Service (RaaS) by 2019. Was this forecast accurate?

The Future is Here with Robot Guidance Systems

Manufacturers are facing a number of challenges, but perhaps the biggest of them all is the implementation of automated material handling solutions. SICK, Inc. has the answer to this problem with a system-solution approach.

Innovative Manufacturers Should Embed Automated Systems in Production Processes

Precision tools improve process control and result in higher product quality.

ManufacturingTomorrow - Special Tradeshow Coverage

IMTS 2018

IMTS 2018 takes place at McCormick Place in Chicago, IL September 10th - 15th. This ManufacturingTomorrow.com Special Tradeshow report aims to bring you news, articles and products from this years event.

Manufacturing Challenges and Industry 4.0

As we move deeper into the Industry 4.0 era, advancements in automation, artificial intelligence, machine learning, cloud computing and big data play an increasingly important role in how factories operate.

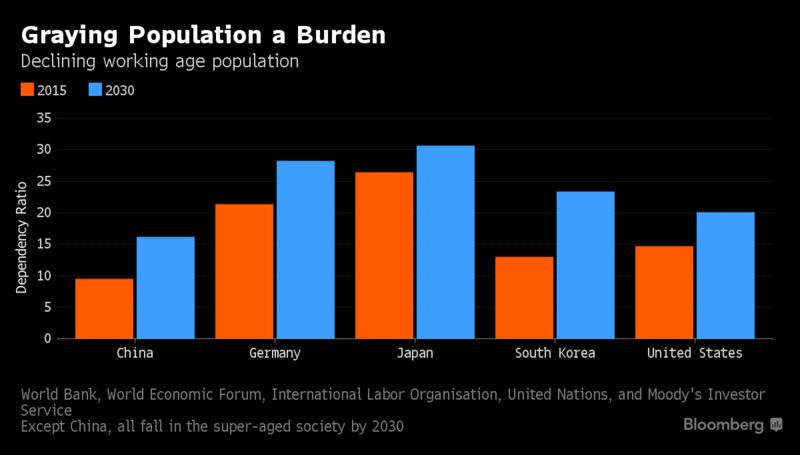

Robots May Help Defuse Demographic Time Bomb in Japan, Germany

Anirban Nag for Bloomberg: Robots to offset negative impact of slower labor force growth. Emerging markets wont be so lucky, Moodys report says

Getting Started with Collaborative Robots - Part 4 - Assess Your Potential Applications

Documenting the actual process will allow you to evaluate if the process can be automated. This will also give you a starting point on cell performance and improvement opportunities.

Records 1 to 10 of 10

Featured Product

T.J. Davies' Retention Knobs

Our retention knobs are manufactured above international standards or to machine builder specifications. Retention knobs are manufactured utilizing AMS-6274/AISI-8620 alloy steel drawn in the United States. Threads are single-pointed on our lathes while manufacturing all other retention knob features to ensure high concentricity. Our process ensures that our threads are balanced (lead in/lead out at 180 degrees.) Each retention knob is carburized (hardened) to 58-62HRC, and case depth is .020-.030. Core hardness 40HRC. Each retention knob is coated utilizing a hot black oxide coating to military specifications. Our retention knobs are 100% covered in black oxide to prevent rust. All retention knob surfaces (not just mating surfaces) have a precision finish of 32 RMA micro or better: ISO grade 6N. Each retention knob is magnetic particle tested and tested at 2.5 times the pulling force of the drawbar. Certifications are maintained for each step in the manufacturing process for traceability.

.jpg)