Factories of the future - What will manufacturing facilities look like in 2044

The landscape of manufacturing is set to evolve dramatically over the next two decades, as cutting-edge technologies redefine the way we produce goods. To envision what the future may look like, we do not need to rely solely on idle speculation.

Don't let delayed ROI delay your investment in smart connected products

Smart connected products can unlock new ways to generate revenue and cost efficiencies. While the payoff may be years away, companies need to invest today to remain not just competitive, but relevant.

The Role of Industrial PCs (IPCs) In Today's Smart Factories

The harsh conditions of factories such as extreme vibrations that may cause screens to crack, drastic changes in temperature and humidity levels, and physical debris have shown us that standard computing devices simply fall short in industrial environments.

Avoiding the Pitfalls: The Biggest Mistakes Manufacturers Make When Creating a Smart Factory

In this article, I will delve into the most common errors manufacturers make when working to create a smart factory, along with advice on how to prevent these mistakes.

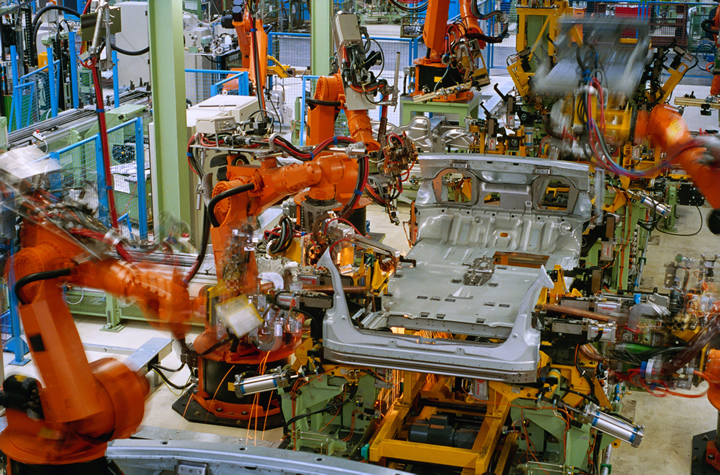

Why Manufacturers Should be All-in on Automation

Over the next five years, it's estimated that 25% of industrial spending will go toward automation. This spending will impact everything from logistics to retail to auto manufacturing and is expected to help improve several areas, including speed, safety, and product quality.

Robotics Providers: Challenges and Opportunities in a Dynamic Industrial Equipment Market

In this blog post, we'll explore some of the key trends and challenges facing robotics providers today, and offer insights into how they can navigate this dynamic landscape to build successful businesses.

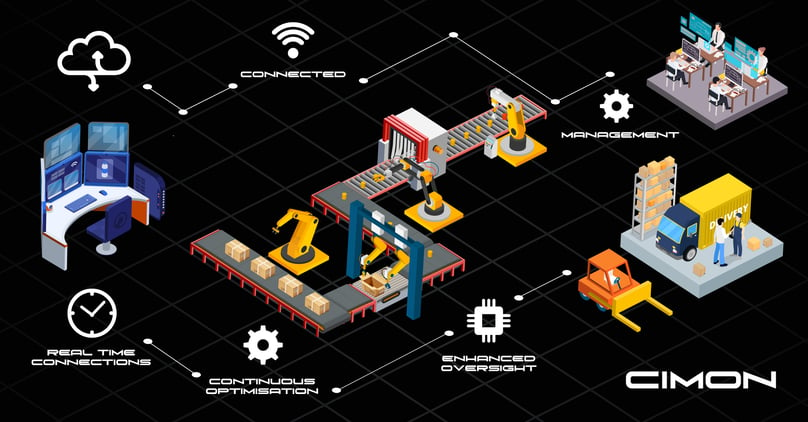

Why smart interconnection is essential for building the factories of the future

Today, the super-high bandwidth and low latency of 5G have tremendous potential to transform all industries, especially manufacturing. They need intelligent networks to ensure manufacturers get the most from their 5G campuses.

INVENTEC COLLABORATES WITH MICROSOFT TO DELIVER SMART FACTORY SOLUTIONS ON MICROSOFT AZURE PRIVATE 5G CORE

The solutions integrate Inventec's 5G private network solutions, NEXCOM's top notch AIoT (AI + IoT) Industry 4.0 cross-border integration systems and solutions, and Microsoft HoloLens to build smart factories.

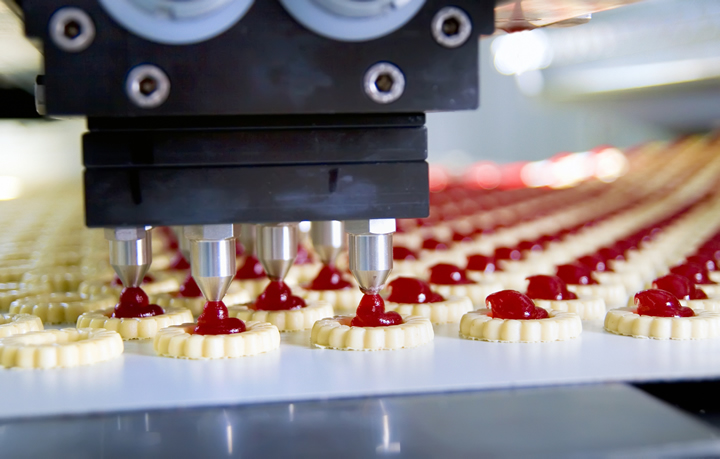

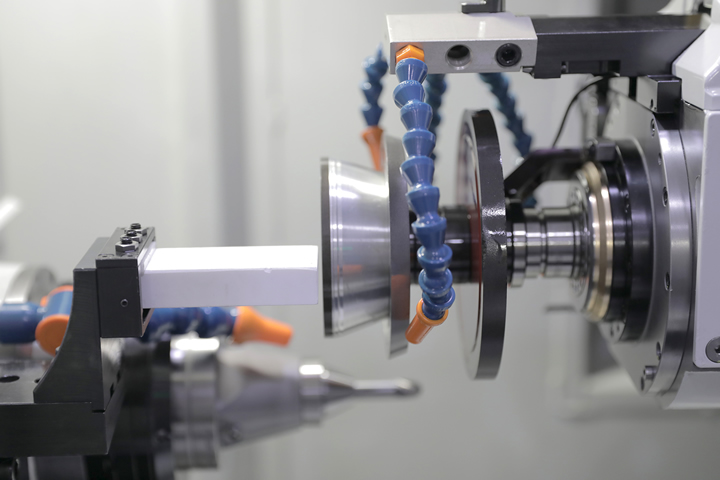

What types of CNC machines will smart factories demand? Will software or hardware rule?

Different types of CNC machines will appear in smart factories. Here's what you need to know about

upgrading and updating your machines.

2022 Top Article - Protect Your Factory Floor Against the Next Global Emergency with IoT

Introducing simple and effective technologies in the right ways can enable manufacturers to get more from their existing operations while also attracting and retaining talent for the long term.

Digi-Key Launches Factory Tomorrow Season 2 Video Series

The three-episode series will take a closer look at the driving forces behind Industry 4.0, interviewing experts in the field about how artificial intelligence (AI), connectivity and edge computing technologies are shaping the next major leap forward for manufacturing.

ASE Unveils Plans for the World's First 5G mmWave NR-DC SA Smart Factory

The collaboration will focus on enabling the digital transformation of factory processes that are highly secured and highly reliable through facilitating 5G wireless infrastructure integration, smart heterogeneous equipment integration and OT security system integration.

Automating Risk Management to Improve Employee Safety in Warehouses

In Guidance Automation's 2022 research, 64% of respondents said that safety concerns around physical accidents caused by automated systems were preventing them from implementing warehouse or manufacturing plant automation.

Three Ways Authentication Technologies Help Smart Factories Cut Costs

Modern authentication and access control systems can help by preventing unauthorized use of machines and ensuring that the correct parts and consumables are used.

Keys to Building More Autonomous Systems Into Manufacturing

Both autonomous manufacturing and hybrid autonomous manufacturing introduce a level of automation never seen before. The system does all the work, with machines and technology as a strong foundation, and people are relegated to monitoring and support.

Records 1 to 15 of 147

Featured Product

Pleora Technologies - Digitize Manual Manufacturing

Vaira™ helps manufacturers digitize, automate, and upgrade error-prone manual processes and decisions to boost productivity and increase profits by helping humans make decisions consistent, reliable, and traceable. The camera-based solution is powered by a scalable suite of shop floor-ready apps built on proven machine vision and AI expertise for frontline manufacturing operations, with two-way integration to resource planning tools to help drive continuous analysis, insight, and improvements. Start digitizing immediately, streamlining processes customized to your unique requirements and reduce errors that lead to costs, delays, and quality concerns.

.jpg)

.jpg)