The most compact Motion Control System on the market

FAULHABER is introducing a new Motion Control System. More precisely: The world's smallest Integrated Motion Controller.

Unlocking Customer Experience: The Critical Role of Your Supply Chain

Cost implications play a pivotal role in delivering exceptional experiences for end-users. By optimizing expenses, businesses can allocate resources to enhance product quality and service delivery, ensuring customer satisfaction.

Three layers of predictive maintenance - New horizons in a world of AI and Big Data

The key difference between preventive maintenance and predictive maintenance is that the latter means completing maintenance only when needed, as opposed to scheduled intervals.

Revolutionizing Sustainability: igus Unveils AI-Driven Solutions for Industry 4.0 at Hannover Messe

Smart maintenance, low-cost robotics, AI-based online tools: igus® showcasing pioneering solutions for the lubrication-free and CO2-neutral industry and automation of tomorrow at the Hannover Messe

Lean is the Future of Manufacturing

Reducing wait times and eliminating extraneous handling and labor through lean improves your bottom line. The capital saved can then be reinvested in new and better products and processes to further improve the customer experience, which in turn fuels business growth.

How Small Manufacturers are Building a Business Case for Robotics

Smaller manufacturers are the fastest-growing area of industrial robotics today, driven by the need for new collaborative robotics systems.

How ML helps manufacturers maintain safer workplaces

This article covers the concept of machine-learning in manufacturing and highlights four use cases of ML improving workplace safety.

Factories of the future - What will manufacturing facilities look like in 2044

The landscape of manufacturing is set to evolve dramatically over the next two decades, as cutting-edge technologies redefine the way we produce goods. To envision what the future may look like, we do not need to rely solely on idle speculation.

Don't let delayed ROI delay your investment in smart connected products

Smart connected products can unlock new ways to generate revenue and cost efficiencies. While the payoff may be years away, companies need to invest today to remain not just competitive, but relevant.

The Benefits of MOM & MES and Why the Differences Matter

Mike Bradford Strategic Business Development Director at DELMIA, takes a closer look at some of the biggest differences between MES and MOM, and why these differences are critical to manufacturing success.

AI Capabilities Your Manufacturing Organization Likely Hasn't Thought About

Aside from its data-rich mining and productivity enhancements, AI can provide advantageous returns to further aid and elevate day-to-day processes.

Foundations for Success In Industrial Automation: A Guide for Small to Medium Manufacturers, Part III

Once you've pinpointed what you will automate, it's time to develop a project roadmap. Here is how to best transform your preparatory efforts into an actionable plan:

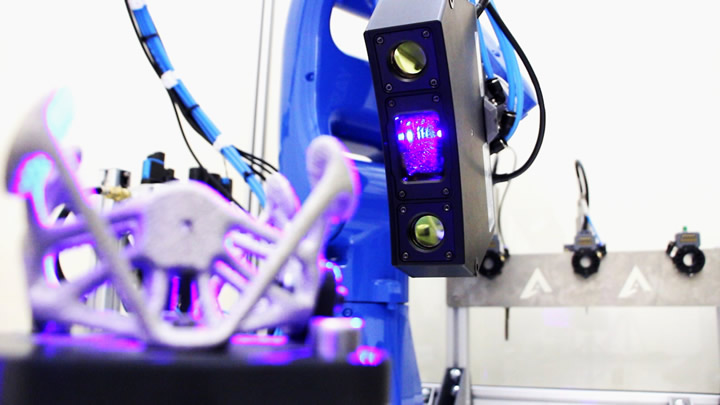

The Evolution of Additive Manufacturing: How Automation Redefines Post-Processing Standards

In 2024, post processing metal parts is still a bottleneck in the AM process chain because it is still very often a manual, labor-intensive, messy (filthy, actually) and sometimes risky task.

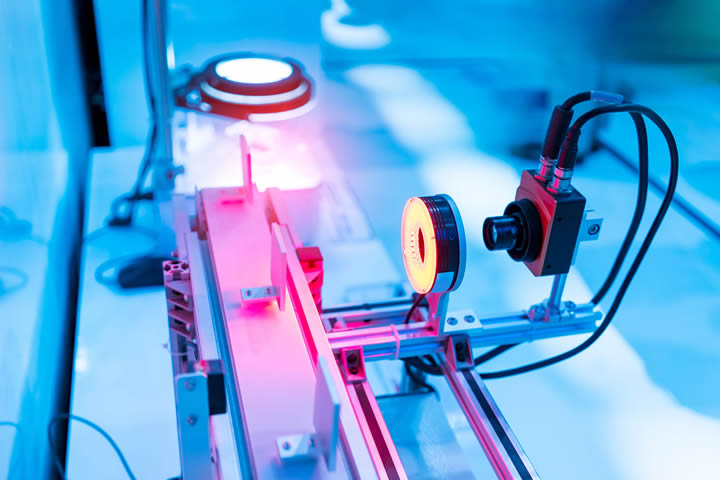

The secret lives of manufacturing defects - How defects pass through the system undetected

Here Zohar Kantor, chief revenue officer at quality inspection pioneer QualiSense, traces how defects enter the manufacturing process and avoid detection.

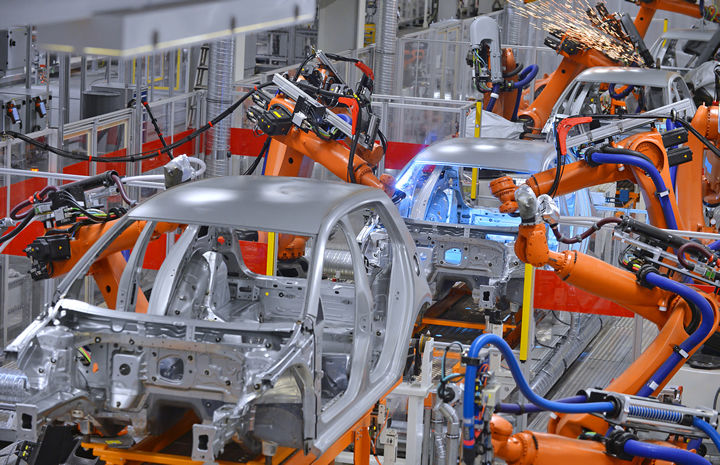

7 Reasons Cloud Data is Driving the Future of Auto Manufacturing

Storing and analyzing auto manufacturing data in the cloud has several advantages automakers can't afford to miss. Here's a closer look at these benefits and why cloud data will drive the future of auto manufacturing.

Records 1 to 15 of 543

Automation & IIoT - Featured Product

CIMON Xpanel eXT & nXT Series HMI

Introducing the Xpanel eXT and nXT series, advanced industrial HMI solutions that set a new standard for performance and usability. Utilizing our brand new Canvas HMI software for project creation, the Xpanel eXT and nXT series deliver a seamless and efficient user experience. They combine industrial-grade touch technology, powerful embedded OS hardware with a quad-core CPU, and an easy-to-use runtime platform. The Xpanel eXT and nXT series are specifically designed to optimize and streamline industrial operations, enhancing your HMI experience.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)