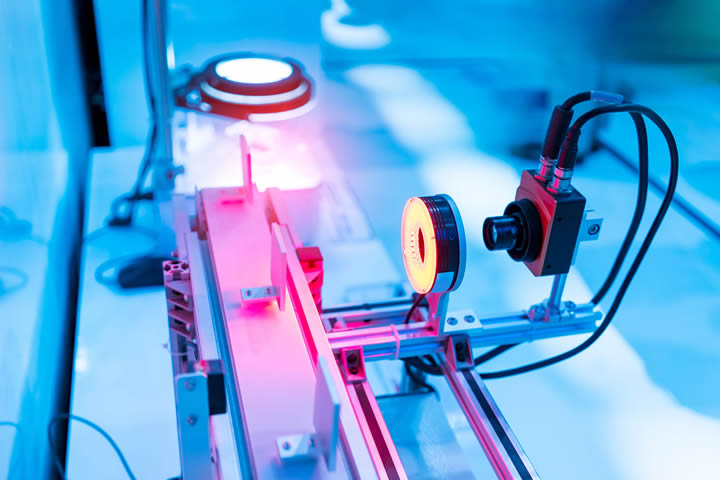

The secret lives of manufacturing defects - How defects pass through the system undetected

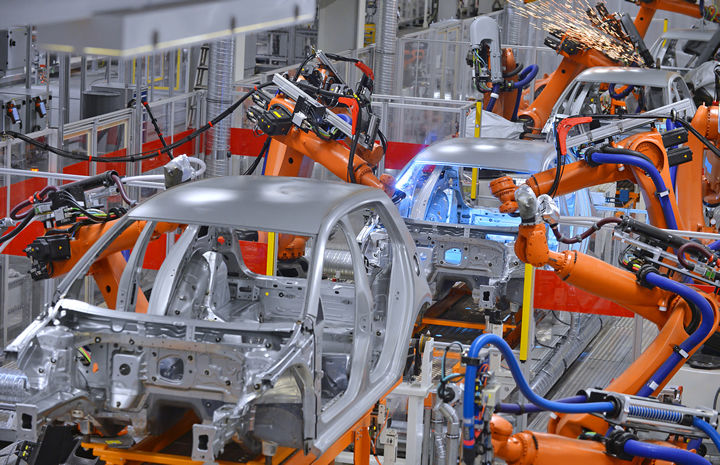

7 Reasons Cloud Data is Driving the Future of Auto Manufacturing

Waste not, want not - rapid identification of metals in scrap

The "Most Expensive Software" Holding Our Factories Back

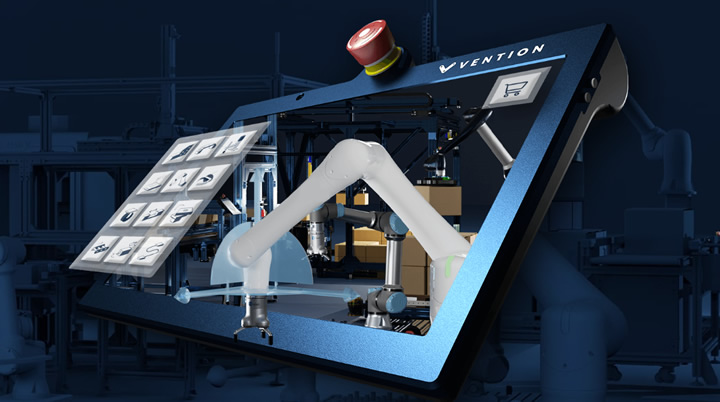

Foundations for Success In Industrial Automation: A Guide for Small to Medium Manufacturers, Part II

Using AI to Fill Blind Spots and Revolutionize Manufacturing Processes

IMTS 2024 Offers Hidden Technology Gems, New Exhibitors

Why More Manufacturers Will Turn to No-Code Platforms in 2024

Foundations for Success In Industrial Automation: A Guide for Small to Medium Manufacturers

A Culture of Proactive Compliance

More assembly processes in a smaller space and using less energy

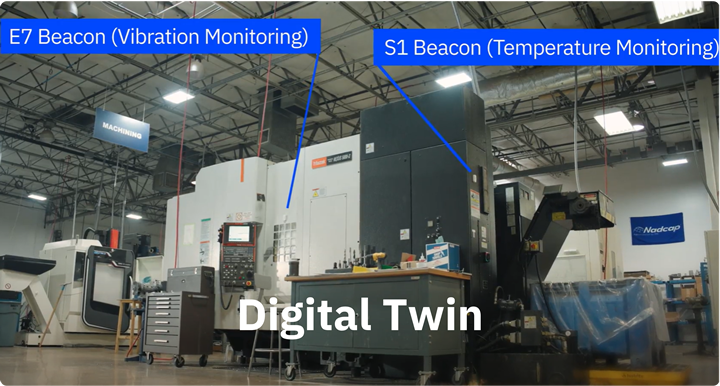

Navigating the future of metalworking in 2024 - Manufacturers turn to digitalised CNC machining and interconnected smart factories

The Whats and Hows of the Ultimate Dashboard for Industrial IoT

Best Practices for Safer Factories in 2024: How to Improve Material Handling Applications

Integrating Heat Pumps in Industrial Processes: 5 Notable Changes

Records 16 to 30 of 545

First | Previous | Next | Last

Automation & IIoT - Featured Product

.jpg)

.jpg)