The ALTRA 280 was engineered to solve a challenge that’s persisted for years: reliably and affordably producing large, complex parts in both engineering-grade and high-performance polymers.

BigRep ALTRA 280, the Ultimate High-Temperature Industrial 3D Printer

BigRep ALTRA 280, the Ultimate High-Temperature Industrial 3D Printer

Product Q&A with Silas Dortmann, Product Lifecycle Manager | BigRep

Tell us about yourself and your role with BigRep.

My name is Silas Dortmann, and I am the Product Lifecycle Manager at BigRep. I’m responsible for connecting technical expertise with market needs to help strategically manage our product portfolio.

I work closely with colleagues across our engineering, marketing and sales teams to support products throughout their entire lifecycle, from pre-development planning to product launch, market presence, and eventual phase-out. This includes creating technical content for global marketing initiatives and gathering market feedback to drive continuous improvements. I also contribute to the product roadmap to ensure our portfolio remains competitive in the market and aligned with customer needs.

Can you share some details on high-temperature Fused Filament Fabrication (FFF) 3D printers and their uses?

High-temperature FFF 3D printers are designed to process high-performance thermoplastics that require much hotter extrusion and chamber temperatures than standard machines provide. Our BigRep ALTRA 280 and our IPSO 105 are examples of such printers.

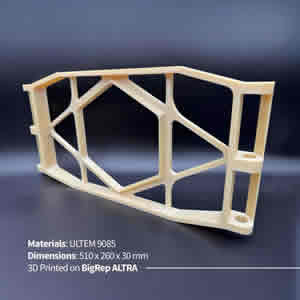

The advantages of these polymers, such as polycarbonate (PC), PEKK or PEI 9085, are that they combine recyclability and processability with high stiffness, strength, thermal stability, and chemical resistance. These are qualities that common thermosets and elastomers cannot offer in the same balance.

By enabling the reliable printing of such materials, high-temperature FFF systems unlock the production of strong, lightweight and durable parts that can withstand demanding environments, the likes of which are commonly found in aerospace and automotive applications.

The ALTRA 280 you mentioned was released last year (2024) as BigRep’s first step into this field of additive manufacturing. What sets it apart from other machines on the market, or in your own portfolio?

The ALTRA 280 was engineered to solve a challenge that’s persisted for years: reliably and affordably producing large, complex parts in both engineering-grade and high-performance polymers. These polymers are difficult even on smaller systems, and the problems only multiple at scale.

The ALTRA 280’s generous 280 liter build volume (hence the name) and welded steel frame create a stable thermal environment, while the water-cooled DSX extruders ensure reliable processing of demanding polymers (up to 450°C). The combination makes printing large, complex components or even several parts at once much more reliable.

Add to that CNC-grade precision and speed thanks to ball screws and servo motors, and you have a system that combines the reliability of industrial machining and flexibility of additive manufacturing.

Who is the ideal customer (industry/application) for the ALTRA 280? Who was this engineered for?

I’d say the ALTRA 280 is meant for industrial users who need to produce larger parts in engineering-grade and high-performance materials. It’s a good fit for sectors like aerospace, automotive, or general manufacturing, where reliability and material performance are important. It can also be very useful for research institutions that explore advanced materials or develop new applications. It was engineered for organizations that want a robust system for both versatile prototyping and end-use parts.

Most extrusion-based 3D printers typically have two extruders, max. The ALTRA 280 has four of them (DSX extruders). What are the benefits of having the four extruders on this machine?

With four extruders, you not only gain material flexibility, such as multiple structural materials in a single print or a combination of structural and soluble support material, but you also gain built-in redundancy. If a spool runs out of material or a nozzle gets clogged, another extruder automatically takes over in Relay Mode, keeping the print going without interruption.

For industrial users running long builds, this increases their efficiency, while also delivering greater uptime. It makes additive manufacturing more viable in demanding production environments.

The ALTRA 280 is designed for “high-performance 3D printing”. Historically materials like PEI 9085 and PEKK are difficult to print with, let alone at this size. What is it about the ALTRA 280 that makes it well equipped to handle these materials?

Materials like PEI 9085 and PEKK are challenging because they require very high and stable process temperatures due to their high glass transition temperatures. Even small fluctuations can cause warping or poor layer adhesion. The ALTRA 280 is designed with that in mind: It has a high-temperature print chamber, extruders that can maintain the necessary processing temperatures, and a rigid frame that keeps the whole system stable.

Materials like PEI 9085 and PEKK are challenging because they require very high and stable process temperatures due to their high glass transition temperatures. Even small fluctuations can cause warping or poor layer adhesion. The ALTRA 280 is designed with that in mind: It has a high-temperature print chamber, extruders that can maintain the necessary processing temperatures, and a rigid frame that keeps the whole system stable.

On top of that, the large build volume is paired with active thermal management, so heat is distributed evenly throughout the print. That combination makes it possible to process these demanding polymers reliably, even at a larger scale.

What does material management look like for the ALTRA 280? Does it offer any protection for moisture-sensitive materials?

The ALTRA 280 is set up with sealed filament bays that keep the material dry and protected, which is important for moisture sensitive polymers. For customers with even stricter requirements, there is also the option to feed the printer directly from the BigRep DRYCON, our external drying cabinet. That way you can make sure the material stays in optimal condition right up to the point of printing.

The ALTRA 280 is set up with sealed filament bays that keep the material dry and protected, which is important for moisture sensitive polymers. For customers with even stricter requirements, there is also the option to feed the printer directly from the BigRep DRYCON, our external drying cabinet. That way you can make sure the material stays in optimal condition right up to the point of printing.

Where are you seeing the most opportunities for a product like the ALTRA 280 to be used? Can you share any use cases?

We see the biggest opportunities in industries that need large, strong, and/or heat-resistant parts, where traditional 3D printers are either too small or not capable of processing high-performance thermoplastics. Aerospace and automotive are clear examples where companies use it for lightweight structural components, housings or ducting.

We’re also seeing use cases in tooling and jigs for industrial production, where the combination of size, reliability, and engineering-grade materials can replace metal tools in certain applications.

And in research institutions, it’s being used to explore new materials and validate designs at full scale. The common thread is applications that demand both material performance and large build capacity.

How does BigRep help customers bridge the gap between a customer’s traditional fabrication process and these more advanced manufacturing methods like the ALTRA 280?

Transitioning from traditional fabrication methods to additive manufacturing can be a big step, so we put a lot of focus on customer support and application training. The process often starts with a member of our application engineering team, who will provide a part and application analysis, and share best practices, such as designing for additive manufacturing.

In addition, our Customer Experience team and global network of resellers provide both remote and on-site technical support. Customers can also make use of our PartLab print services to test or validate applications before scaling up or investing in a BigRep printer of their own.

By combining that support with real use cases, we help them integrate the machine into their workflow step by step and build confidence in the technology.

To learn more about the BigRep ALTRA 280 and BigRep’s large-format 3D printing solutions, visit bigrep.com.”

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

BigRep

Founded in 2014, BigRep set sail to transform the 3D printing and manufacturing business. With its 1m3 volume, the BigRep ONE opens the gateway to a new dimension of 3D printing and 3D manufacturing, while the BigRep STUDIO allows fast and precise large-scale 3D printing. From furniture to vehicles to robotics, we think everything is possible. We want you to envision everything from human scale robot parts, sculptural artworks in all their full-dimensional glory, and dream the impossible world-changing designs of tomorrow while enabling you to print them today using one of our 3D printers.

Other Articles

How 3D Printing is Paving the Way for Grading Contractor, C.J. Moyna & Sons

3D Printing Produces Engine Covers To Accelerate Aircraft Maintenance

3D Printing Powers Wind Turbine Research At TU Berlin

More about BigRep

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product