Additive Manufacture: In-house 3D Printing versus Outsourced 3D Printing Service

In this 3-part series of articles, we will embark on a comprehensive exploration of 3D printing / additive manufacturing (AM), where our main focus is empowering you to make informed decisions about how to engage with the technology across an ever-evolving landscape.

Winds Of Change For Vestas: 3D Printed Tooling Transforms Wind Turbines

There aren't a lot of technologies that can propel towering wind turbines to new heights of time and cost efficiencies, but large-format additive manufacturing rose to the challenge and delivered with its eclectic range of applications.

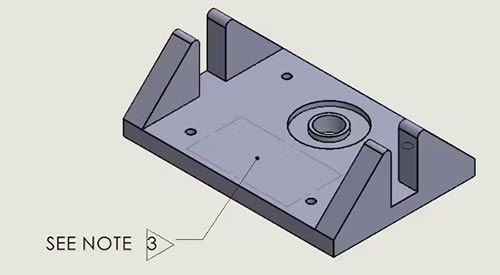

How to Create A Good Technical Drawing

Make sure your drawing undergoes all quality assurance and approval procedures. A drawing that is easy to follow and clearly defines your requirements is one of the first steps to a successfully manufactured part.

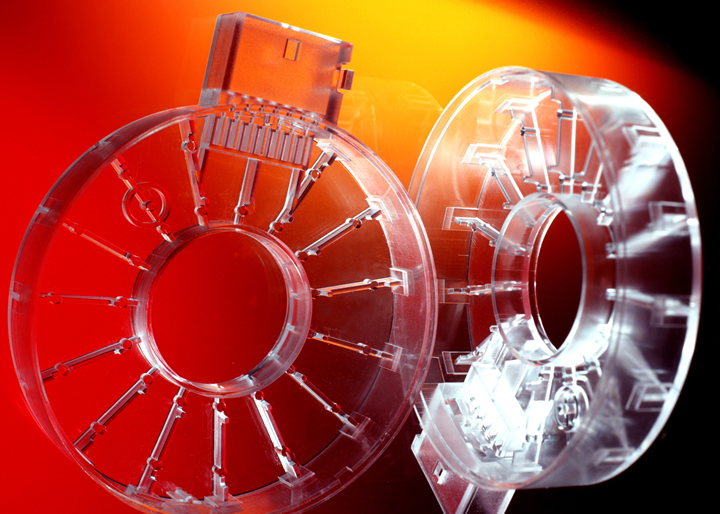

THE IMPACT OF 3D PRINTING ON MICRO MOLDING - A SYNERGISTIC APPROACH

The precision achieved in micro molding is not just about miniaturization, it's about reproducing complex shapes with exacting tolerances that are measured in microns repeatably.

3D Printing Powers Wind Turbine Research At TU Berlin

On average, wind turbine blades are a massive 80 meters long. When it comes to reengineering these towering blades, no other technology offers the freedom, precision, and adaptability to scale parts quite like 3D printing.

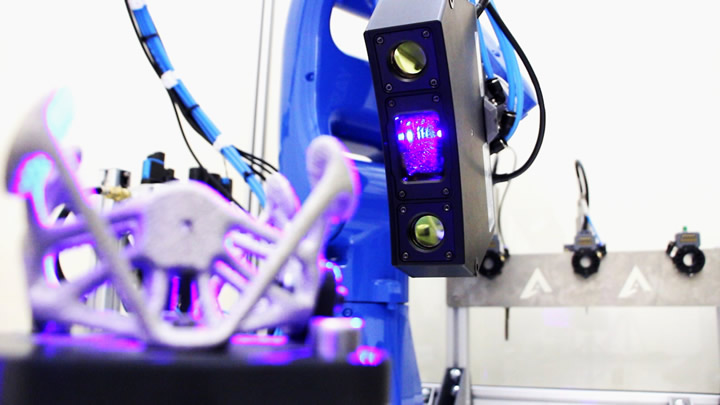

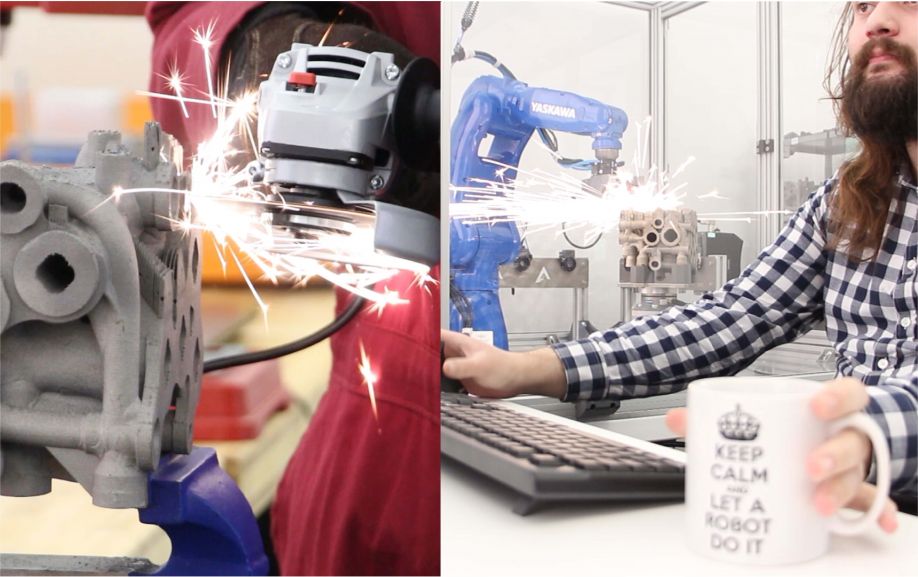

The Evolution of Additive Manufacturing: How Automation Redefines Post-Processing Standards

In 2024, post processing metal parts is still a bottleneck in the AM process chain because it is still very often a manual, labor-intensive, messy (filthy, actually) and sometimes risky task.

THE RISE OF AUTOMATION IN METAL AM POST-PROCESSING - TRANSFORMING THE INDUSTRY WITH PRECISION AND EFFICIENCY

We delve into how automation in metal AM post processing is setting a new industry standard, and how companies like Rivelin Robotics are leading this change with their Netshape® Robots to unlock new productivity and efficiency gains.

NANO DIMENSION'S TERA 250vx ENHANCES ACCUMOLD'S MICRO INJECTION MOLDING SERVICE

Today, Micro-Additive Manufacturing (Micro-AM) solution like the Tera 250vx from Nano Dimension can additively manufacture or 3D print micro parts and components only previously possible through the use of micro injection molding.

The Future of Computer Aided Manufacturing & Fabrication

Playing a key role in ensuring that automation is incorporated into the fabrication process helps to keep things moving along as quickly and efficiently as possible for manufacturing businesses around the world.

What's in store for 2024: Top 5 industry trends

The manufacturing industry is undergoing significant changes due to the swift advancement of technology and evolving global dynamics.

This 3D printer can watch itself fabricate objects

Computer vision enables contact-free 3D printing, letting engineers print with high-performance materials they couldn't use before.

Expanding US-based Additive Manufacturing Services

Fictiv's robust digital supply chain infrastructure is growing every day. We have a highly vetted network of US-based additive manufacturing partners like Jabil Additive that enable customers to get the highest quality 3D printed parts delivered quickly

Companies Collaborate to Build Giant Guitar Installation in Liverpool

Diamond Precision Engineering was tasked with making a giant guitar to mark the 80th birthday of Sir Paul McCartney.

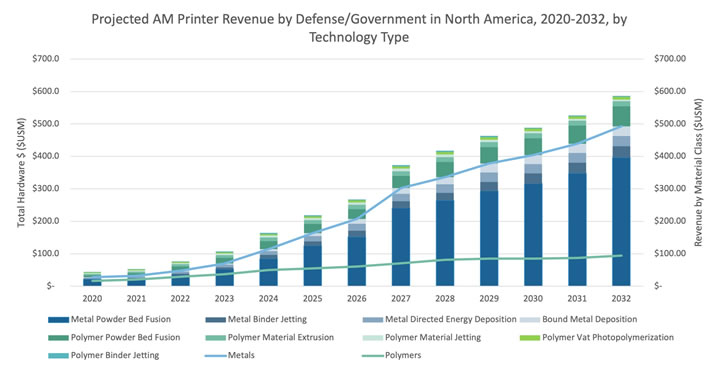

AM Research Publishes In-Depth Market Study on Additive Manufacturing for Military and Defense; Estimates $0.3B in Direct DoD Spend in 2023, Growing to $1.8B in 2032

The comprehensive study sheds light on the rapid evolution and potential impact of additive manufacturing technologies on the defense and military landscape.

Why 3D Metal Printing Is Key to the Future of Aerospace Engineering

The aerospace industry constantly pushes the boundaries of what's possible, and the demand for advanced manufacturing techniques has never been more critical. This pursuit of innovation has led to a significant shift toward 3D metal printing.

Records 1 to 15 of 754

Additive & 3D Printing - Featured Product

bigrep PRO - INDUSTRIAL QUALITY MEETS COST EFFICIENCY. COMPLEX PARTS IN LARGE SCALE.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

.jpg)

.jpg)