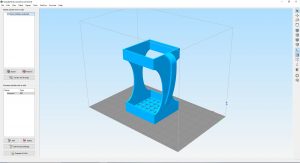

One of A3D’s engineers met with the individual to best understand their specific situation and designed a handle that could attach to standard milk and juice cartons. A3D then used Simplify3D to print the handle.

3D Printing Assistive Devices for People with Disabilities

3D Printing Assistive Devices for People with Disabilities

Case Study from | Simplify3D

Access 3D Services is a rapid prototyping and engineering firm using additive manufacturing to empower people with disabilities. The firm designs and produces custom assistive devices and durable medical equipment for people living with a disability. They also provide a wide range of 3D printing services to a variety of industries including academia, business, and medicine.

3D Printing for a Cause

Access 3D Services (A3D) is a subset of Access Independence, a nonprofit organization dedicated to “promoting independence and opportunities for people with disabilities through advocacy, empowerment, and education,” explains Joe Eckert, Operations Director of A3D. Originally a 3D printing services bureau, the firm has expanded to include engineering, design, 3D printing, CNC services, and 3D scanning. A3D provides these services to a wide range of clients and industries and donates all proceeds to people living with disabilities.

3D model of a handle that can attach to a carton

A3D stays connected to the disability community by “exploring potential solutions to everyday problems encountered by individuals with disabilities and how our 3D services program can help to make those solutions a reality,” describes Eckert. When an individual with a spinal cord injury was unable to grip a beverage container without a handle, A3D was determined to find a solution. One of A3D’s engineers met with the individual to best understand their specific situation and designed a handle that could attach to standard milk and juice cartons. A3D then used Simplify3D to print the handle and ensured a snug fit, allowing the individual to pour their own drinks from a carton again.

Saving Time with Simplify3D

Four years ago, A3D switched from an open-source slicer to Simplify3D. Their previous slicer made it difficult to keep up with printer updates, new machines, and repairs. After trying Simplify3D, A3D adopted it as their exclusive slicer for all of their 3D printers. “We have separate profiles set up for each machine with different bed surfaces, materials, and other specifications, which allows us to easily switch between different machines and materials,” Eckert describes.

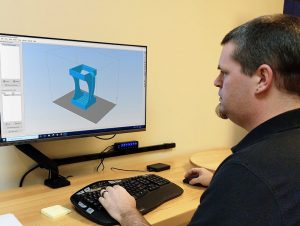

A3D Engineer using Simplify3D Software

The A3D team uses a variety of Simplify3D tools to save time and resources for the company and its clients. They frequently use multiple processes to quickly test and optimize settings for their models. “By setting up multiple processes and applying each to a different model on the same build plate, we can take a trial and error approach and reach optimized settings much faster than having to print a single model at a time.”

Taking Complexity to the Next Level

With a team of talented experts coupled with a powerful slicing software, A3D has been able to take on very complex projects for other businesses and clients. When Quinnipiac University was unable to successfully print a difficult model of an ancient infant skull with their own engineering team, they contracted A3D to print it for them. “The model was generated from a CAT scan and was extremely thin-walled with countless holes and disconnected surfaces within the model,” Joe elaborates. “Simplify3D allowed us to separate the disconnected surfaces, remove them, and create multiple processes to set appropriate settings for different parts of the model so that it would print properly with dissolvable HIPS supports. The University was extremely pleased with the results.” Projects like this allow A3D to generate additional funding for people with disabilities. Going forward, A3D continues to support their clients and the disabilities community in every way they can through the power of 3D printing and engineering.

3D printed replica of an ancient artifact for client

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product