BTM INDUSTRIAL IS HOSTING AN ONLINE SALE OF INDUSTRIAL ROBOTS ON DECEMBER 17-18, 2025

Includes more than 200 robots designed to automate tasks, such as welding, manufacturing, packaging, warehousing, and food processing. This court-authorized sale requires the liquidation of all assets, regardless of price.

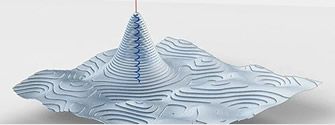

NewsFender's 3D Printed Ballistic Fender Charts a New Course in Maritime Defense

Discover how NewsFender's 3D printed customizable, eco-friendly fenders and boat parts are making waves in the maritime defense industry.

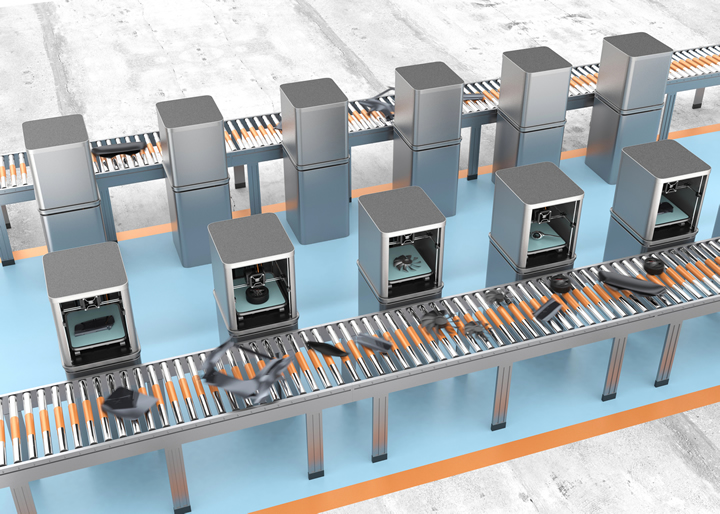

9 Evidence-Backed Predictions for the Next Decade of Auto Part Manufacturing

As the industry navigates the next decade, it will adapt to the digital transformation and the emergence of smart vehicles. Here are nine evidence-backed predictions for the next 10 years of auto part manufacturing.

Photonics Array Alignment: Precision Active and Passive Techniques for High-Throughput PIC Production

In this post, we explore the evolution of photonics alignment - from early manual single-fiber setups to today's fully automated FAU (Fiber Array Unit) alignment systems.

3D Printing Revolution: How Localized Manufacturing Is Reshaping Global Trade

In the realm of advanced manufacturing, robotic large-format additive manufacturing (LFAM) is rapidly emerging as a strategic tool for businesses seeking to bypass traditional trade constraints and build more resilient operations.

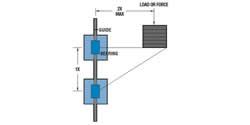

What is the 2:1 Ratio For Linear Plain Bearings?

The 2:1 Ratio represents the maximum allowable moment arm distance relative to bearing length without causing binding or motion restriction, ensuring optimal performance in plain linear bearings.

ProMat Q&A with binder USA

We are exhibiting for the first time and offering exclusive opportunities to connect directly with our experts in circular connectivity. This is the perfect chance to familiarize yourself with our high-quality products, including our new launches.

How 3D Printing is Paving the Way for Grading Contractor, C.J. Moyna & Sons

At C.J. Moyna & Sons, being on the lookout for disruptive technologies is a part of his everyday routine. When they set on a path to integrate additive manufacturing into their daily processes, the work became easier for C.J. Moyna & Sons and their sister companies.

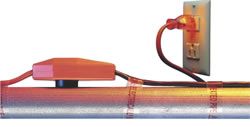

Heat Tracing in Hydrogen Processing, Storage & Transportation

In this article, we look at hydrogen's path forward to a sustainable, clean hydrogen future, and address current industry requirements for safe and efficient production, conversion, transportation, and storage.

3D Printing and Sustainable Auto Manufacturing: A Glimpse into the Future

The excitement around 3D printing in the automotive industry is easier to understand in light of growing sustainability needs. While vehicles themselves may be the most obvious target for emissions reductions in this sector, the production side needs improvement, too.

Audi Sport Accelerates Design and Production Processes with trinckle Software and UltiMaker 3D Printers

When the new Audi E-Tron GT was introduced, the Audi Sport BÃ'llinger Höfe location in Heilbronn, Germany, rapidly needed almost 200 new tools, jigs and fixtures for its production. Designing these tools costs a lot of time.

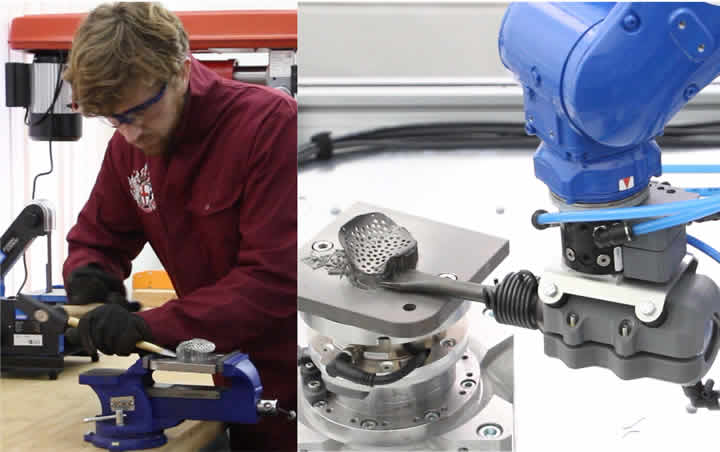

CLEANING UP AM'S DIRTY SECRET

The fact that post processing metal parts requires such intensive manual intervention throws up a series of follow-on problems. These include part-to-part quality inconsistencies, repetition fatigue, significant health & safety risks.

The Use of Gearboxes in Warehouse Automation

It's crucial to prioritize data management before jumping into implementing analytics. Because different departments and processes produce different data types, a common data language is a good place to start to help structure the data and break down silos.

Thermal Imaging Technology in Lithium-ion Battery Manufacturing

Thermal imaging technology enhances battery quality during manufacturing by identifying material discrepancies and thickness variations in battery electrodes. This ensures that only high-quality electrodes are used, improving battery performance and safety.

Selecting the Right Adhesive-backed Mounts for the Best Use

Adhesive-backed mounts, or "sticky-backs" as they are sometimes referred to, come in three types: rubber-based, acrylic-based, and high bond (which is an enhanced acrylic-based adhesive). Each of these are unique and provide their own set of strengths and drawbacks.

Records 1 to 15 of 84

Featured Product

Elevate your manufacturing processes with data-driven insights

Join Emerson and discover how embracing a Floor to Cloud™ strategy can revolutionize your operations. This strategy integrates on-site devices and technologies with cloud analytics, providing the insights needed to enhance manufacturing efficiency, maximize workforce potential, and achieve sustainability targets. Our team of experts have a commitment to innovation and look forward to discussing your challenges to develop a customized solution.

Manufacturing and Automation - Featured Company

Teledyne FLIR

Teledyne FLIR designs, develops, manufactures, markets, and distributes technologies that enhance perception and awareness. We bring innovative sensing solutions into daily life through our thermal imaging, visible-light imaging, video analytics, measurement and diagnostic, and advanced threat detection systems. Teledyne FLIR offers a diversified portfolio that serves a number of applications in government & defense, industrial, and commercial markets. Our products help first responders and military personnel protect and save lives, promote efficiency within the trades, and innovate consumer-facing technologies. Teledyne FLIR strives to strengthen public safety and well-being, increase energy and time efficiency, and contribute to healthy and intelligent communities.

.jpg)

.jpg)