What role does automation play in the manufacturing supply chain?

Adrian Wood, Strategic Business Development Director at DELMIA, gives us some very informative and interesting insights into automation's integral role in the manufacturing supply chain.

CAPTURE 3D Enables Fast Digitalization of Extra-Large Objects with the ZEISS ATOS LRX

CAPTURE 3D makes the fast digitalization of very large parts possible with the ZEISS ATOS LRX accurate 3D scanner engineered for fields such as heavy casting, shipbuilding, aerospace structures, automotive and wind energy.

Reaping Good Harvest: Artec Leo Offers Innovation to Improve Harvesting in France

The company 3D scans parts with high precision to adapt or reproduce them for machine modifications like a core cleaning module or an enhanced sowing system.

3D Laser Scanning for 2D Applications for the Liquid Storage Petrochemical Industry

Think of a liquid fuel/petrochemical storage facility as a living, breathing entity. And the P&ID is the roadmap for how its innards function and how these disparate physical parts work and fit together.

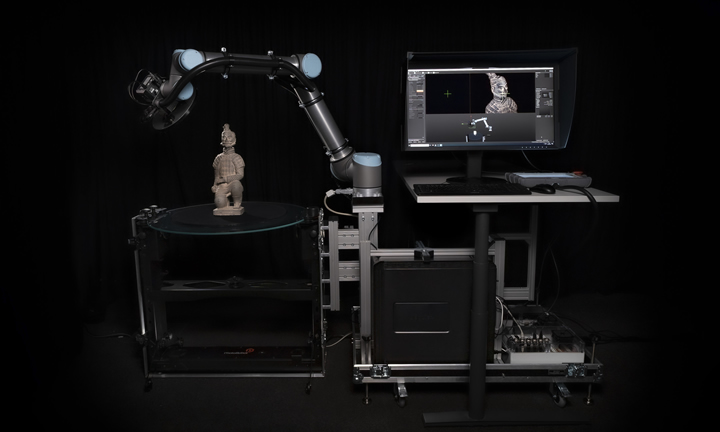

Fraunhofer IGD Develops Automated Robotic Arm to Scan Cultural Objects in 3D, Now Cooperating With Phase One

The Fraunhofer IGD has developed a product to make it easier for museums to digitize their collections and is now cooperating with Danish camera manufacturer Phase One. The mobile scanner CultArm3D delivers precise 3D models of exhibits of various sizes at the push of a button.

Records 1 to 5 of 5

Featured Product

T.J. Davies' Retention Knobs

Our retention knobs are manufactured above international standards or to machine builder specifications. Retention knobs are manufactured utilizing AMS-6274/AISI-8620 alloy steel drawn in the United States. Threads are single-pointed on our lathes while manufacturing all other retention knob features to ensure high concentricity. Our process ensures that our threads are balanced (lead in/lead out at 180 degrees.) Each retention knob is carburized (hardened) to 58-62HRC, and case depth is .020-.030. Core hardness 40HRC. Each retention knob is coated utilizing a hot black oxide coating to military specifications. Our retention knobs are 100% covered in black oxide to prevent rust. All retention knob surfaces (not just mating surfaces) have a precision finish of 32 RMA micro or better: ISO grade 6N. Each retention knob is magnetic particle tested and tested at 2.5 times the pulling force of the drawbar. Certifications are maintained for each step in the manufacturing process for traceability.