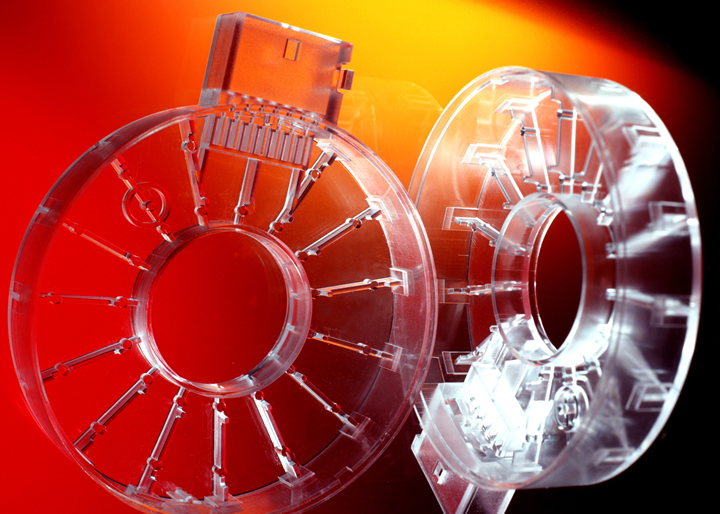

THE IMPACT OF 3D PRINTING ON MICRO MOLDING - A SYNERGISTIC APPROACH

The Benefits of MOM & MES and Why the Differences Matter

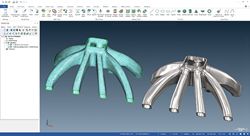

Practical Reverse Engineering - Choosing the Right Tools for the Job

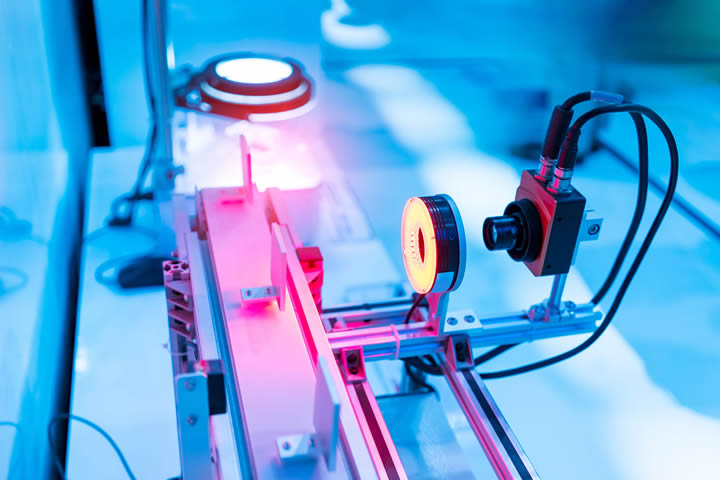

How Ethernet Cameras Are Making a Comeback with New, Powerful Features

3D Printing Powers Wind Turbine Research At TU Berlin

AI Capabilities Your Manufacturing Organization Likely Hasn't Thought About

Foundations for Success In Industrial Automation: A Guide for Small to Medium Manufacturers, Part III

A Packaging Look-Ahead for 2024 and Beyond

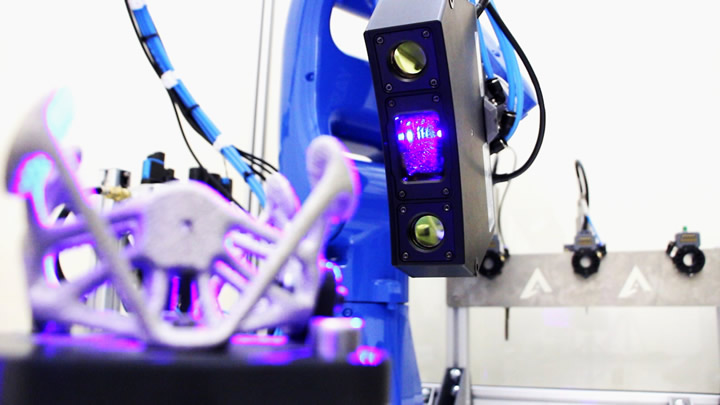

The Evolution of Additive Manufacturing: How Automation Redefines Post-Processing Standards

Industrial AI begins: Curse or blessing?

MODEX 2024 - Special News Feature

The secret lives of manufacturing defects - How defects pass through the system undetected

Specialty Food Manufacturer Meets FDA Requirements and Sustains Growth with MRP Software

Preparation - Is a Key. How to Address Challenges of IoT Development at Discovery

Daifuku-Wynright: Manufacturing Visibility & Control with Quickbase

Records 31 to 45 of 2672

First | Previous | Next | Last

Featured Product

.jpg)

.jpg)