Preparation - Is a Key. How to Address Challenges of IoT Development at Discovery

Despite the redoubled efforts made to fix issues, more than half of the IoT projects are considered unsuccessful by their initiators. For some reason, companies often prefer to ignore this fact.

State of Reliability and Hardware Design

Every industry we serve-from high-performance computing and consumer devices to automotive, electrification and connected healthcare-is impacted greatly by user experience

Reverse Engineering for a Model-Based World

The list of reverse engineering applications is long and will continue to grow as engineers create new and creative ways to use the technology.

Looking to the Future: Visual Commerce in Manufacturing

The reality is B2B buyers increasingly expect interactive and engaging commerce offerings. It's time for manufacturers to up their digital commerce game to keep B2B customers coming back.

New Ideas, Collaboration Help Brenton Drive Four Major Product Handling Upgrades to KW Container

This cell included four robots picking lids and packing them into one of four SKUs. This cell, encapsulated in a small footprint, also included an auto adjustable case sealer to accommodate the four different SKU boxes, a palletizer and stretch wrapper.

Exploring Manifold Design

Manifolds are complex parts that require several levels of expertise to optimize. At Inkbit, we are optimizing the manufacturing of manifolds that finally unlock the geometric freedom of additive manufacturing.

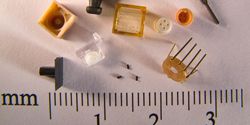

How to Approach Make Vs. Buy Decisions for Optic Assembly

Before making a decision, it's important to analyze whether making or buying optical parts and components is the best approach for your team, budget, and business goals.

Overcome Automation Challenges to Create a Better Smart Factory

Manufacturers must know what challenges they face and how to overcome them to make the most of these investments. Here are the most common automation challenges and how to address them.

Exploring Additive Manufacturing Opportunities: Optimizing Production with Hyundai Lifeboats

The journey to finding success in AM is no simple task. Materialise Mindware, our 3D printing consultancy team, outlined the various steps to steer customers through this journey. Discover how they guided Hyundai Lifeboats through the first phase.

When Should You Use 3D Printing for Production?

There are many reasons why 3D printing may be suitable for your hardware design and development cycle. But what about using 3D printing for full-scale production? Here are some considerations when deciding whether to use 3D printing for high-volume, end-use custom parts.

Risk Mitigation in Micro Molding

In applications where overall tolerances are measured in microns, there are various ways that micro molders mitigate the risks associated with each step of the design-to-manufacturing cycle.

Rittal Automation Handbook Identifies Areas of Improvement and Efficiency

You can lower labor costs, increase accuracy and reduce processing time by automating the control panel modification process. The Rittal Automation Systems Handbook identifies products that provide solutions to all of these plus more.

Decoding Business Valuation: What Manufacturers Need to Know (Part 3)

In part three of this article series, we highlight the overall valuation process, as well as an analysis of factors both internal and external to the business. Here are part one and part two of this series.

ManufacturingTomorrow - Special Tradeshow Coverage

FABTECH 2018

FABTECH takes place in Atlanta, GA November 6th - 8th. This ManufacturingTomorrow.com Special Tradeshow report aims to bring you news, articles and products from this years event.

Advanced Software Design Technology Leads GM into Next Generation of Vehicle Lightweighting

Alliance with Autodesk includes advanced AI-based generative design technology and 3D printing advancements to help lighten and transform future vehicles

Records 1 to 15 of 18

Featured Product

bigrep PRO - INDUSTRIAL QUALITY MEETS COST EFFICIENCY. COMPLEX PARTS IN LARGE SCALE.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

.jpg)