Winds Of Change For Vestas: 3D Printed Tooling Transforms Wind Turbines

New Cutting Parameters AI solution automatically generates appropriate physics-based precision machining feeds and speeds, transforming CNC machining

VAC-U-MAX, GEMCO, VORTI-SIV Team Up to Unveil AM-MPRR at Rapid + tct 2024

ZYGO WORKS HARD TO SECURE SIGNIFICANT COST SAVINGS FOR ZEGAGETM PRO IN BRAZIL

CRP Technology Showcases Cutting-Edge 3D printed Solutions for Drones and Aerospace at AERO 2024

Anycubic Unveils 2024 Strategy to Refine 3D Printing Experience

Velo3D Announces Bookings Totaling $27 Million Since Mid-December - Backlog Now Totals $23 Million

Prima Additive announces the entry of Sodick into its share capital and a Business Alliance

RAPID + TCT 2024: North America's Largest Additive Manufacturing Event Returns to the West Coast With New Features and Experiences

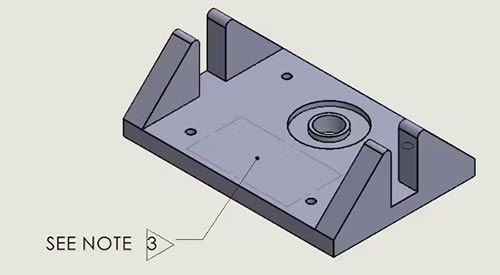

How to Create A Good Technical Drawing

Solar Panel 500w 590w 600w Manufacturer

Excellent Electrical Insulation Performance for Windform Composites

Bally Ribbon Mills Highlights High Performance 3-D Woven Composites

Stratasys Establishes New Customer Advisory Board to Drive Collaboration and Innovation in Additive Manufacturing

Records 16 to 30 of 4535

First | Previous | Next | Last

Additive & 3D Printing - Featured Product